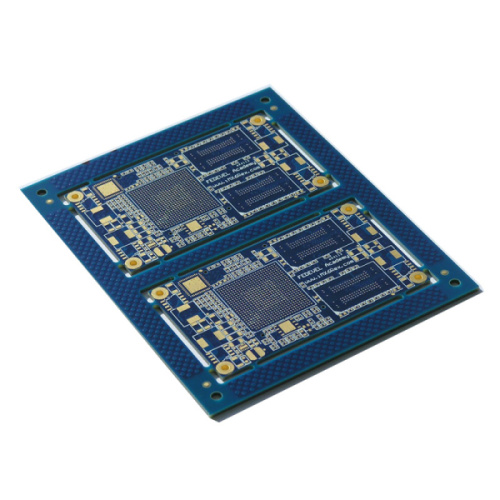

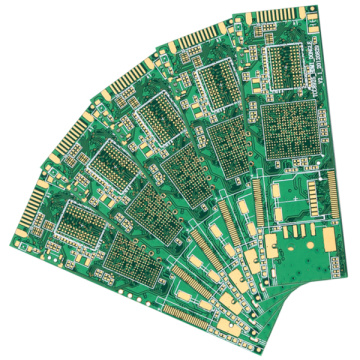

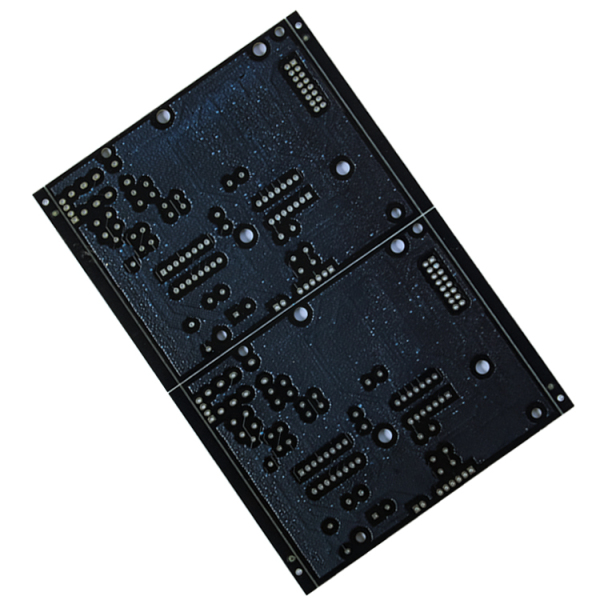

lead-free PCB is customized for American customers

-

$0.98≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

Product Description

Product Description

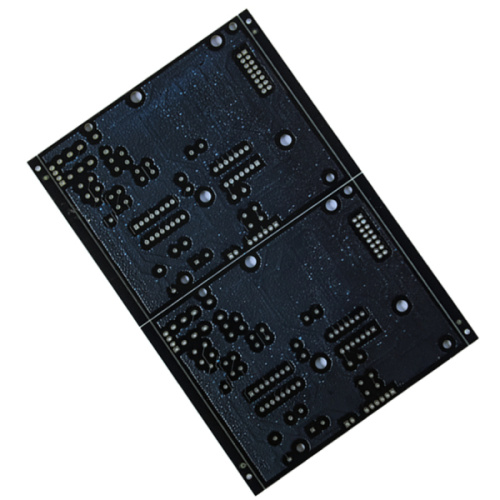

What is a lead-free PCB?

OEM circuit board applications cover a wide range of consumer and commercial products, from automobiles to microwave ovens to IoT devices that automate smart facility functions.

For many years, PCB manufacturers have been dealing with industry challenges and responding with an influx of new technologies and practices. These include miniaturization of PCBs, flex pcb, rigid flex pcb, and the growing demand for green electronic products.

What are lead and lead-free solder made of?

Lead solder (also known as SNPB solder) is a metal alloy with lead (Pb in the periodic table) and tin (Sn in the periodic table) as the basic components. Many years ago, the use of lead pipes and any water supply pipes connected with lead solder was banned in the new American piping system. Before long, the occupational risks of lead soldering were also taken into consideration, and lead-based solders became a documented health hazard in the workplace. Dust and fumes from lead soldering operations are considered toxic when inhaled.

For these reasons, lead solder continues to be eliminated due to its negative impact on the environment and health. But as a product manufacturer, you still want your contracted partners to provide components with reliable solder connections and High Quality Prototype PCB Fabrication.

Lead-free solder is an alternative to traditional 60/40 and 63/37 SnPb solder. In 2006, the European Union (EU) passed the Restriction of Hazardous Substances Directive (RoHS), followed by the United States, offering tax relief to any company to reduce the use of lead-based solder. Today's lead-free solder formulations have the following different percentages:

copper

tin

silver

nickel

Zinc

bismuth

antimony

The ultimate goal is to select high-quality solder alloys that, when combined with other trace metals, will achieve excellent mechanical properties.

When considering the soldering temperature, this will depend on the alloy combination and quality, but usually 60/40 tin/lead solder will become liquid at 361°F. The higher the tin content, the higher the melting point and product cost. Lead-tin solders are easier to use, they have good fluidity and can reach operating temperature faster.

However, in terms of safety, lead-containing solders are very risky and can only be used when permitted by regulatory agencies. It must also be handled properly. Lead is harmful to the environment, toxic to the body, and has the risk of being quickly absorbed into the blood.

Lead-free solder paste will melt at a higher temperature of approximately 422°F. Although higher temperatures require changes in soldering methods, it has been proven that joints soldered with lead-free solder paste are reliable.

Since the wettability of lead-free solder paste is not as good as that of leaded solder, the appearance of solder joints will be different.

Other factors to consider

The reliability of any welded joint or circuit operation will depend on reducing or eliminating welding defects. To do this, many factors must be considered, including:

temperature

vibration

Tin whisker

Warm-up time and output

Operator skill level

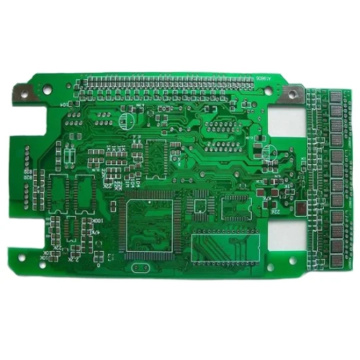

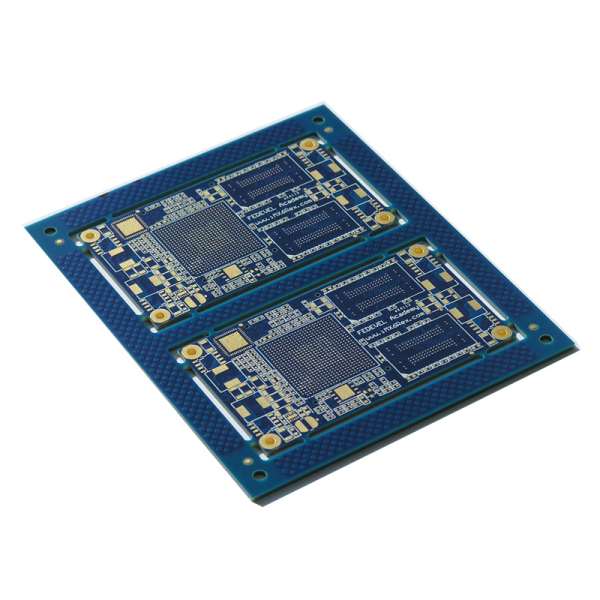

All these factors, including the use of high-quality solder paste, will play a role in the manufacture of reliable PCBs. For lead-free solder, the bottom line is to choose the right formula and match it to the right application. This is where your PCB manufacturer is a valuable asset. Ideally, your partner has extensive experience in RoHS material compliance.

When looking at solderability and the quality of lead-free solder and leaded solder joints, expect lead-free solder to have a strong mechanical connection. Lead solder forms shiny and smooth solder joints to improve appearance quality. However, for PCB and other internal PCB components, consumers rarely notice this difference.

Impact on different types of welding

The use of lead-containing solder paste and lead-free solder paste will also affect the quality of the final product. But again, when PCB manufacturers implement strictly controlled soldering parameters, the impact will be minimized. The design layout of the circuit board and the correct selection of components will overcome many quality control problems.

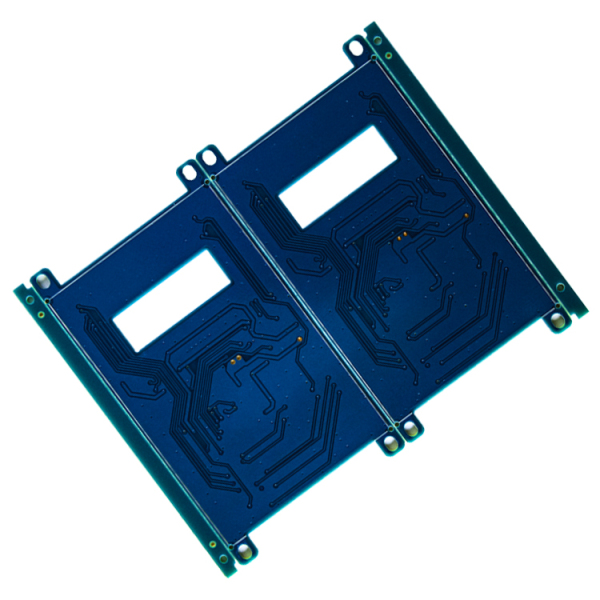

The choice of lead-free products for wave soldering or through-hole soldering is determined according to the specific design parameters of the final assembly PCB and the product usage requirements.

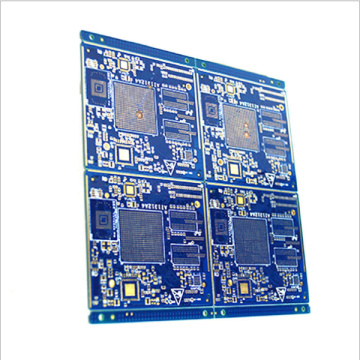

The higher temperatures associated with lead-free soldering mean that correct circuit board layout and component selection are essential to prevent metal decomposition or damage to sensitive Electronic Components. This is especially true during PCBA Manufacturing reflow, because high temperatures can exist for a long time.

ROHS and your contract PCB manufacturer

High-quality consumer products require good solder joints, will not introduce hidden resistors into the circuit, and will not act as a thermal intermediary that may promote thermomechanical fatigue. When you specify the use of lead-free solder in PCB manufacturing, the possibility of cold-dry joints that lack mechanical strength is reduced.

Your PCB manufacturer should help you deal with all RoHS material compliance issues that affect your electronic PCBs. As the US market is gradually shifting to lead-free soldering practices, many companies are following the EU's RoHS lead standard to restrict the use of lead in electronic products. This means that your device can be manufactured in the United States and sold in Europe.

A single modification of soldering materials and/or technology can change the entire PCB/device assembly and manufacturing process. Your PCB contractor’s goal is to ensure that your PCB and final product are manufactured in an efficient and economical manner without sacrificing time to market.

Related Keywords

Related Keywords