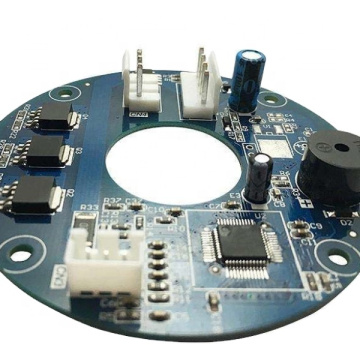

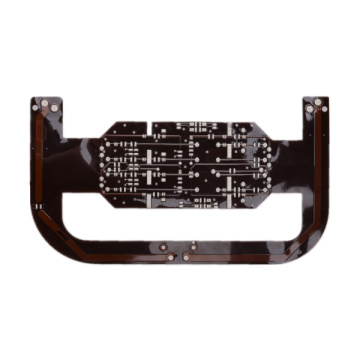

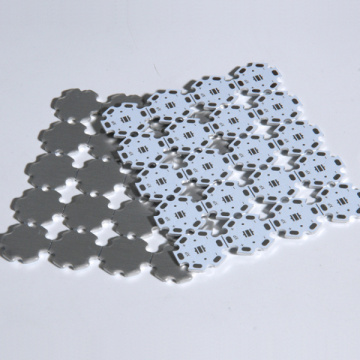

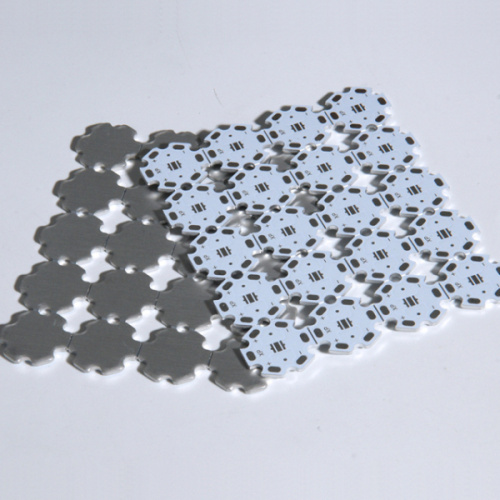

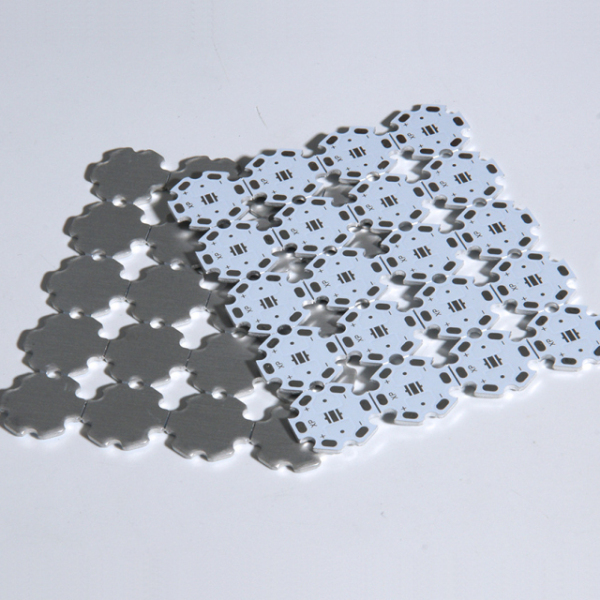

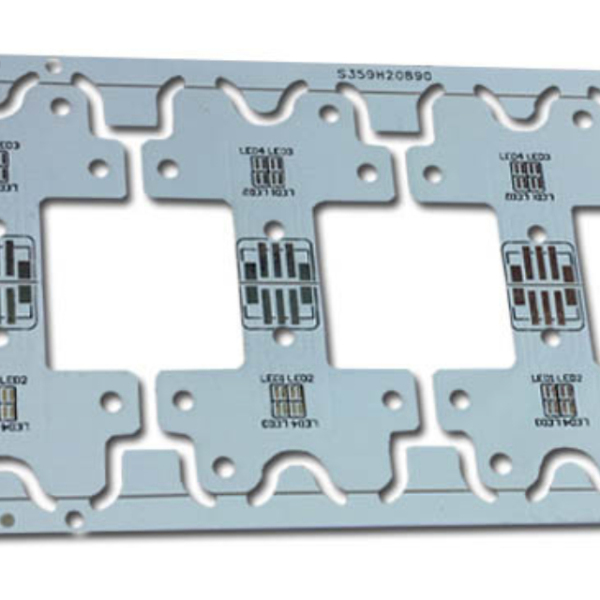

ceramics base copper-clad laminates Aluminum amplifler pcb

-

$32.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact NowWhat is the difference between through hole and surface mount soldering?

Traditionally, Through Hole Technology (THT) has been used to build most printed circuit boards (PCBs). In recent years, the use of surface mount technology (SMT) has become increasingly popular and has gradually replaced Through-Hole Assembly insertion technology.

01. What is through-hole insertion technology?

Through-hole insertion technology inserts components with tails or leads into pre-drilled through holes on the PCB. These Through-Hole Assembly are penetration components. Then the leads can be soldered to the pads or the pads on the bottom of the board, usually using the Wave Solder for PCBA process (or manual soldering).

The new development of the process is to change from ordinary drilling to plated through holes. Apply solder paste to the hole, and then pass the wire through the solder paste. Then the entire PCB is heated to reflow the solder paste, which is called through-hole reflow soldering. This development allows through-hole and surface-mounting to build circuit boards together, because these two types of components can be soldered in one process.

Through-Hole Assembly technology can produce a powerful mechanical combination, so it is very reliable and a mature process. Compared with surface mount technology, Through-Hole Assembly technology has fewer variables that may cause soldering problems, and they are usually fully studied and understood. However, this process makes the bare board more expensive due to the additional drilling and possible requirements of the PCB printed on both sides. It is also difficult to automatically arrange the components on the PCB, because many penetrating board components are loosely packaged or packaged in batches in other ways.

02. What is surface mount technology? How to do it?

Surface mount technology is a method for assembling electronic circuits in which components are directly mounted or placed on the top surface of a printed circuit board.

Surface mount devices (SMD) have flat coplanar tails or leads that allow components to be placed on flat exposed tracks on the PCB. There is no need for small holes on the PCB, and the exposed area is covered by applying solder paste through the template. Then put the component (usually by machine) into the solder paste, and then heat the PCB to reflow the solder paste.

No small holes are required, and surface mount components are sometimes smaller than through-hole components because they use smaller leads or contact bottom surfaces instead of leads. This allows the PCB to become smaller and more compact, with higher circuit density, or at least a cheaper design, with no small holes, and circuit printing on only one side of the circuit board.

Although PCB surface mount technology costs are often lower than through-hole mounting technology, the capital investment required for machinery is often higher. In addition, the design, production, skills and technical level of surface mount technology are usually more advanced than through-hole mounting technology. However, this will be offset by higher throughput with fully automated settings, and the investment will also be paid off by speeding up production.

Related Keywords