Reverse Engineering of Printed Circuit Boards

-

$32.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact NowHow do you reverse engineer multilayer PCB?

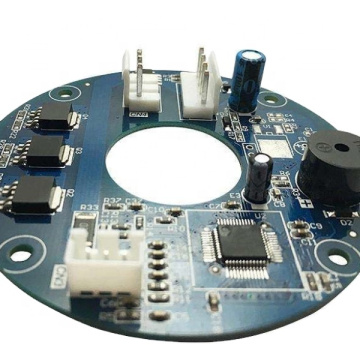

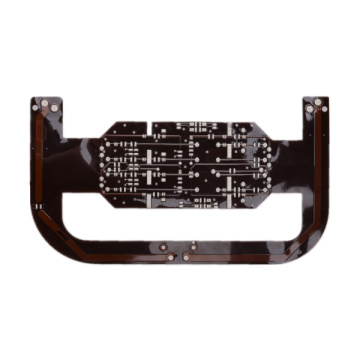

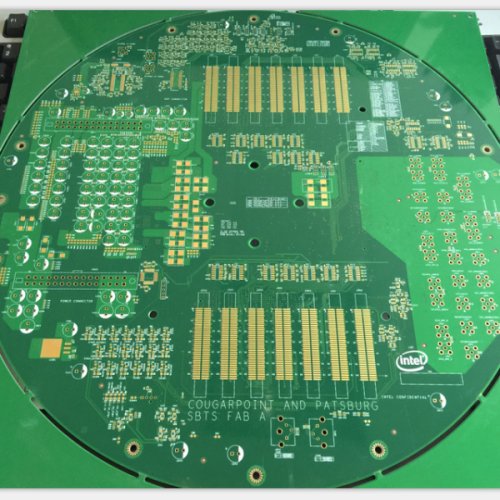

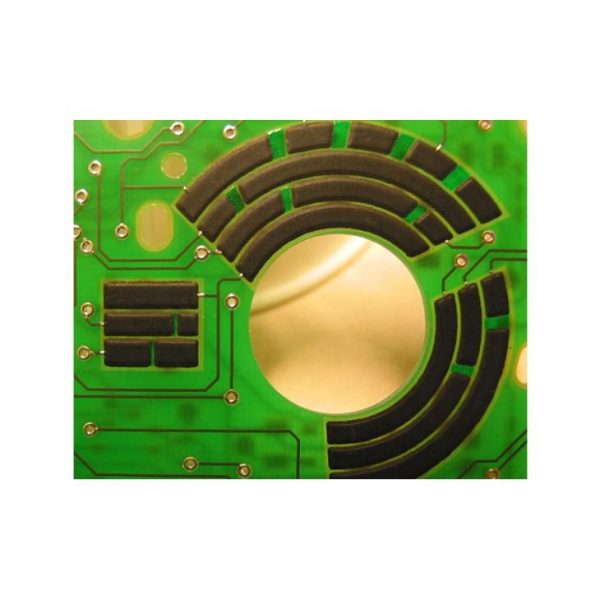

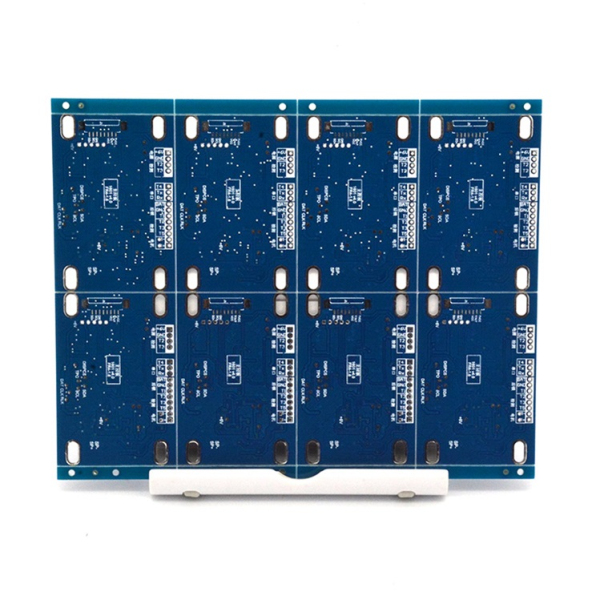

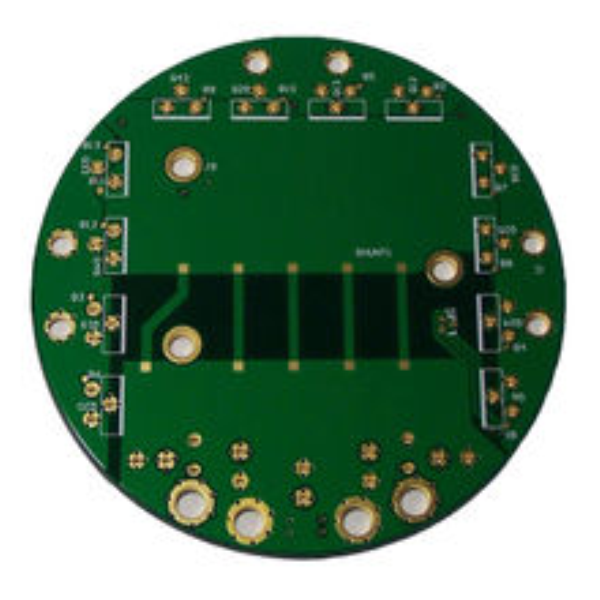

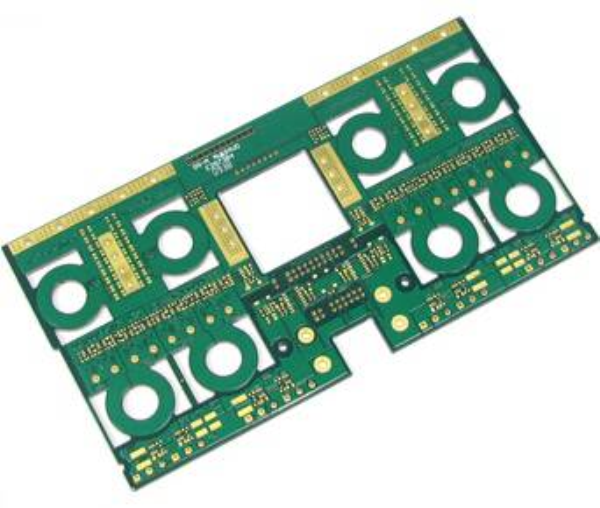

PCB reverse engineering, also known as PCB copy board, is to use reverse R&D technology to reversely analyze the circuit board on the premise that there are already physical products and circuit boards, and the original product PCB files and bill of materials ( BOM) files, schematic files and other technical files and PCB silk screen production files are restored 1:1, and then these technical files and production files are used for custom pcb fabrication, Surface-Mount (SMT) &BGA Assembly, flying probe test, circuit Board debugging, complete copy of the original circuit board template.

The technical realization process of PCB reverse engineering is simply to scan the PCBA of the board to be copied, record the detailed Electronic Components location, and then disassemble the Electronic Components to make a bill of materials (BOM) and arrange the material purchase. The scanned picture is processed by the copying software to restore the PCB board drawing file, and then the PCB file is sent to the plate making factory to make the board. After the board is made, the purchased Electronic Components are soldered to the made PCB board, and then the PCBA test and Just debug.

At the same time, reverse engineering is committed to the secondary development of the original product design ideas. Through circuit principle analysis and data extraction, new design concepts and functional modules are added to the product design to quickly achieve innovative upgrades and updates on the basis of the original product. The replacement will help enhance the overall competitiveness of the electronics industry.

Related Keywords