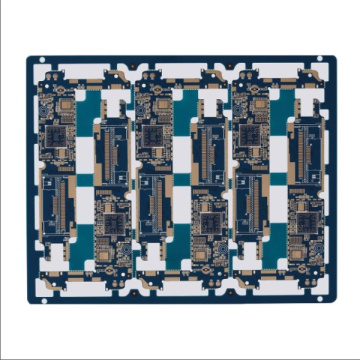

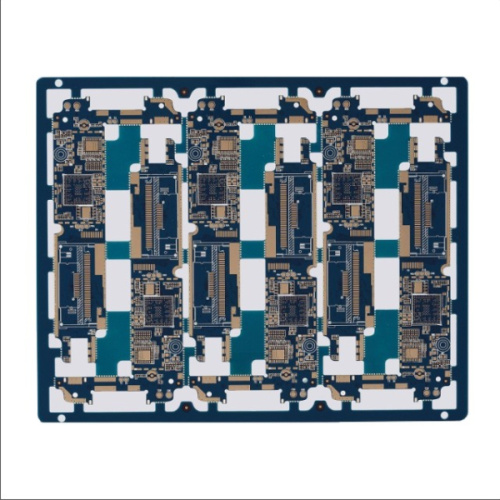

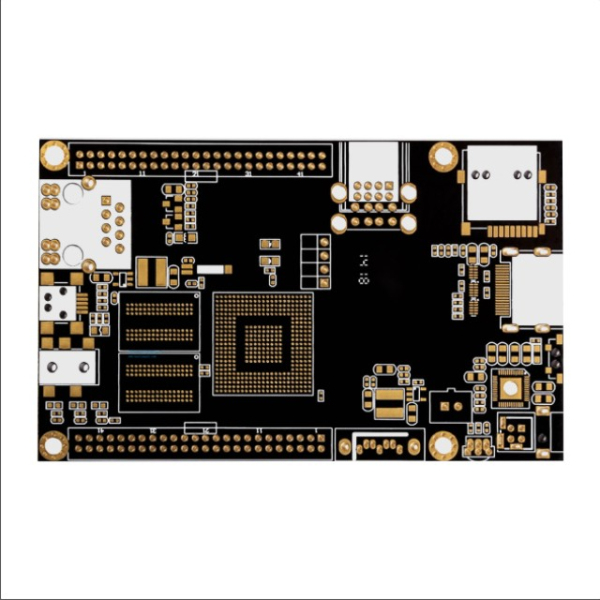

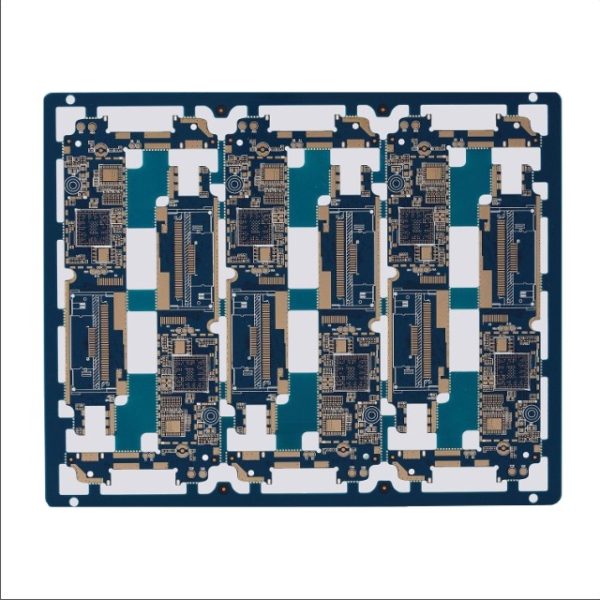

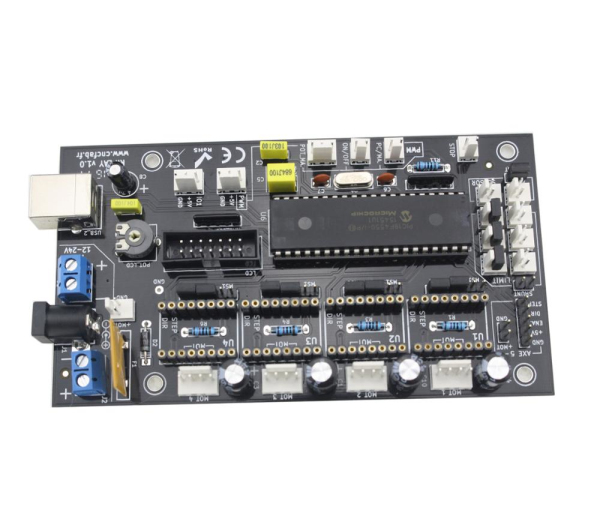

Multilayer Electronic PCBA Printed Circuit Board Assembly

-

$0.50≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact NowHow do you assemble the circuit board?

The PCB assembly or PCBA Manufacturing process of a printed circuit board (PCB) includes many steps. All these steps should go hand in hand to achieve good PCB assembly (PCBA). The synergy between one step and the previous step is very important. In addition to this, the input should receive feedback from the output, which makes it easier and more convenient to track and resolve any errors in the early stages. What steps are involved in the PCB assembly process?

Step 1: Add solder paste: This is the initial stage of the assembly process. At this stage, solder paste is added to the component pads wherever soldering is required. Put the solder paste on the pad and paste it in the correct position with the help of the soldering screen. This screen is made of PCB files and has holes.

Manual: This kind of inspection is usually carried out for smaller components, and the number of components does not exceed one hundred.

Related Keywords