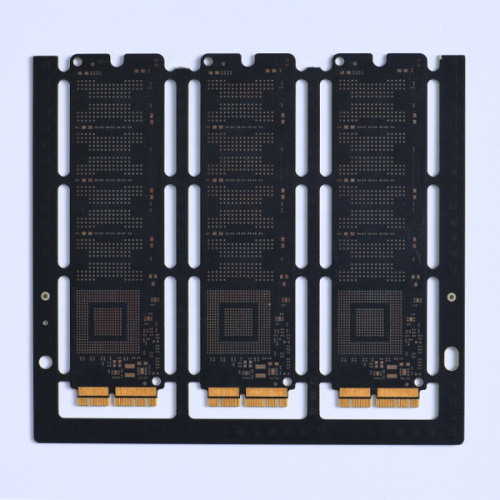

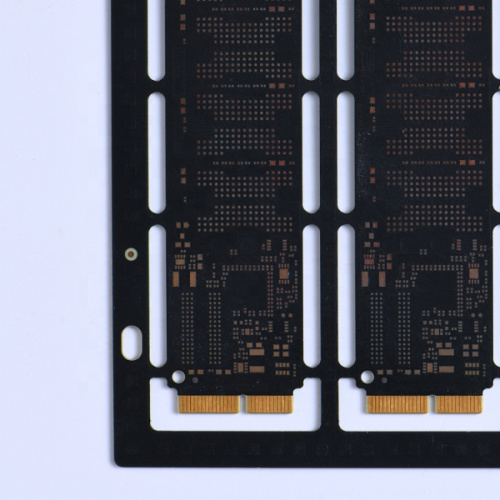

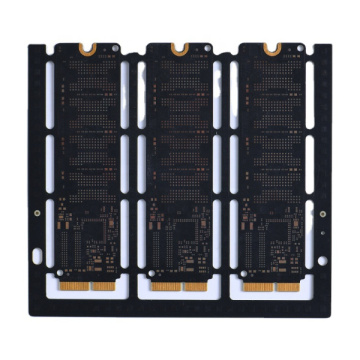

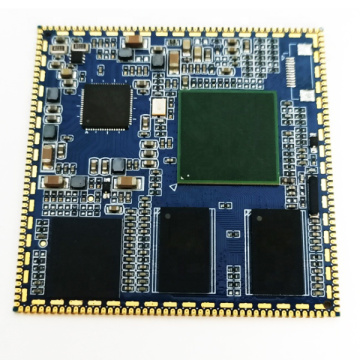

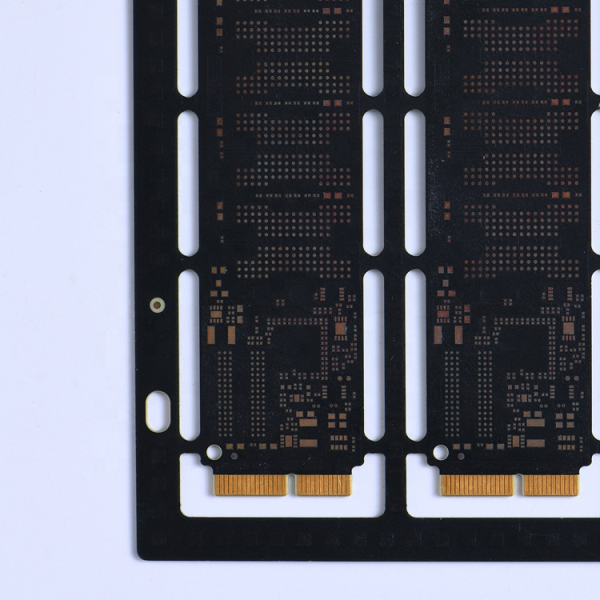

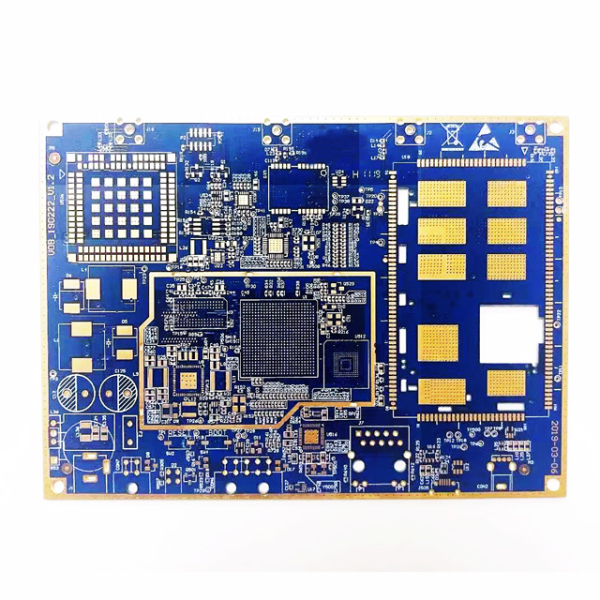

buried/blind via hole PCB PCBA

-

$120.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

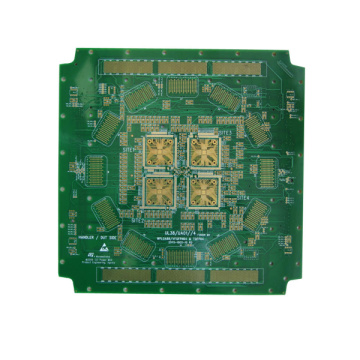

Contact NowWhat is blind via in PCB?

Blind Via Hole, which connects the outermost circuit of the PCB with the adjacent inner layer with electroplated holes. Because the opposite side cannot be seen, the Blind Via Hole PCB is called a "blind-through board." In order to increase the space utilization of the PCB circuit layer, a "blind via" process has emerged. This production method requires special attention to the depth of the drilling (Z axis) to be just right. This method often causes difficulties in electroplating in the hole, so it is almost used by no manufacturer; it is also possible to place the circuit layers that need to be connected in the individual circuit layers in advance. At that time, the holes should be drilled first, and then glued together, but a more precise positioning and alignment device is required.

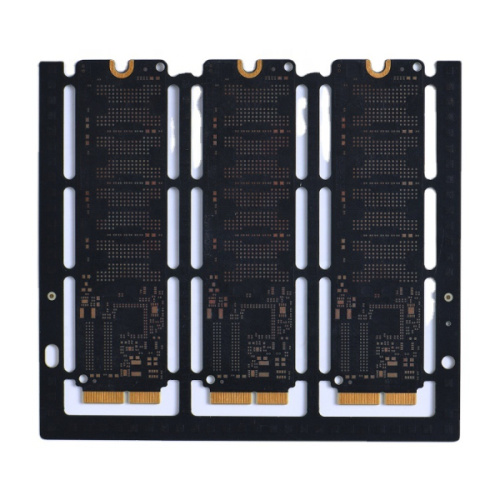

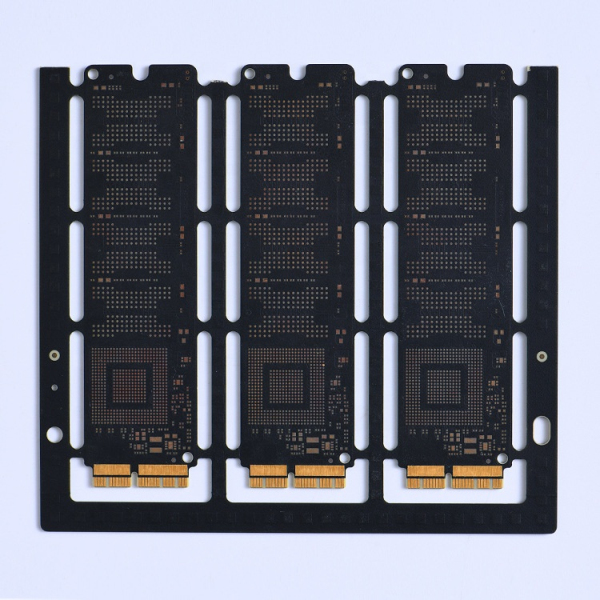

In non-through via technology, the application of blind vias and buried vias can greatly reduce the size and quality of PCBs, reduce the number of buried PCB and blind via hole PCB layers, improve electromagnetic compatibility, increase electronic product features, and reduce costs. It will also make the design work easier and faster. In traditional PCB design and processing, through holes can bring many problems. First, they occupy a large amount of effective space, and secondly, a large number of through holes are densely packed in one place, which also creates a huge obstacle to the inner layer wiring of the multilayer PCB. These through holes occupy the space required for the wiring, and they intensively pass through the power supply and the ground. The surface of the wire layer will also destroy the impedance characteristics of the power ground wire layer and make the power ground wire layer ineffective. And the conventional mechanical method of drilling will be 20 times the workload of non-through hole technology.

Due to the non-through via technology, there are few large vias on the PCB, which can provide more space for routing. The remaining space can be used for large-area shielding purposes to improve EMI/RFI performance. At the same time, more remaining space can also be used for the inner layer to partially shield the device and key network cables, so that it has the best electrical performance. The use of non-through vias makes it easier to fan out the device pins, making it easy to route high-density pin devices (such as BGA packaged devices), shortening the wiring length, and meeting the timing requirements of high-speed circuits.

Related Keywords