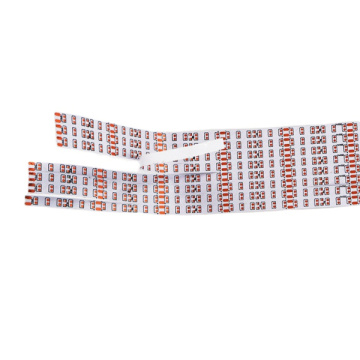

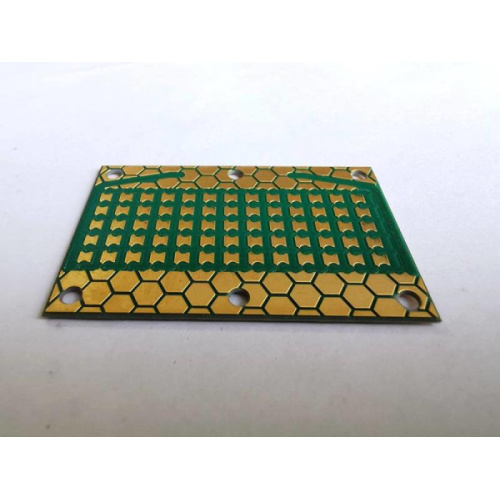

LED PCB board sensor UL Certificate aluminum pcb

-

$0.22≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact Now

How to make ceramic PCB?

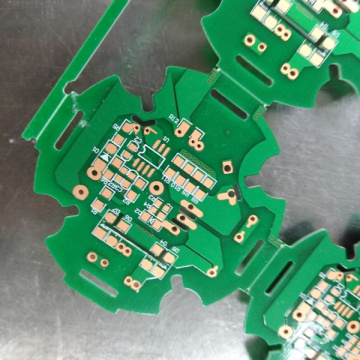

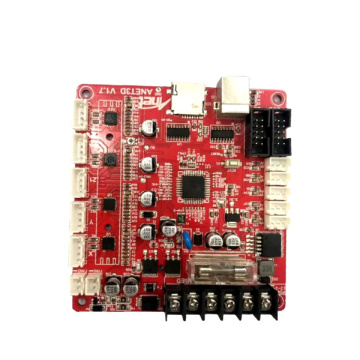

With the rapid development of power electronic circuits in the direction of integration and modularization, various new types of power Electronic Components continue to emerge, and the demand for power electronic devices continues to increase, resulting in an increasing demand for high-performance PCBs. At the same time, with the development of electronic, communication and other equipment in the direction of miniaturization, light weight, high reliability and high speed, especially to meet the needs of Surface-Mount (SMT) & BGA Assembly, the preparation of high-performance PCBs tends to be miniaturized and chip-type The development of high-quality, multi-layer, thin-film, and high-reliability directions requires PCBs with high stability, high thermal conductivity, high temperature resistance and low high-frequency loss.

Ceramics are widely used in high-power power semiconductor modules, semiconductor refrigerators, and electronics due to their high insulation, high chemical stability, high thermal conductivity, and thermal expansion coefficient matching a variety of semiconductor device materials. In heaters and high-power power electronic circuits.

The thick film method is mainly a high melting point metal method, including mo-mn method, silver-based brazing, screen printing, active metal powder sintering. It is made by coating paste on the ceramic surface and sintering in a heat treatment furnace. Part of the process needs to be carried out. Hydrogen reduction secondary treatment. This type of process has no restrictions on ceramic materials. The metal coating and ceramic have high bonding strength, but the disadvantages are very obvious. The processing temperature is above 900°C, high energy consumption, long production cycle, and low efficiency. It cannot be used to make multilayer and thin-film high-performance ceramic PCBs. It is mainly used as a seal between ceramics and metals, and has limited applications in the field of ceramic PCBs.

Thin film methods are mainly cvd/pvd, electroplating/electroless plating, and sputtering methods. This type of process can coat different types of ceramic surfaces with metal coatings, but the coating is thin, with many procedures, low efficiency, and high cost. This type of process As a supplementary process for patterning the metal layer on the ceramic surface, it has limited application in the field of ceramic pcb.

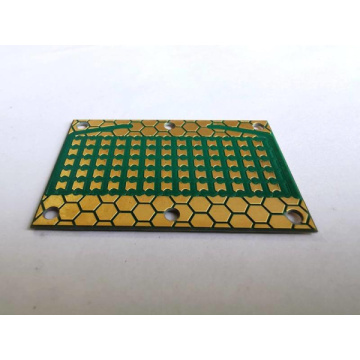

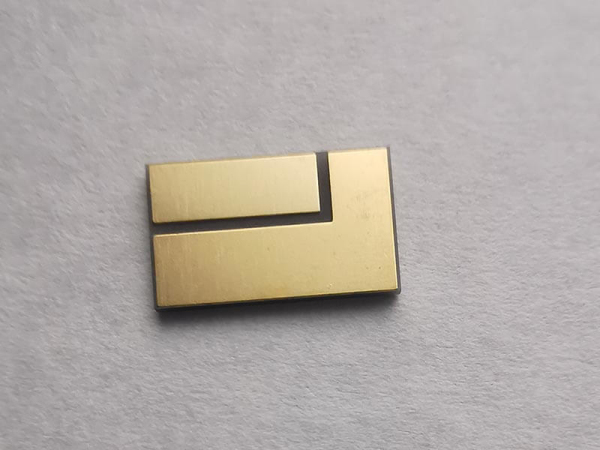

ceramics base copper-clad laminates is the abbreviation for direct bonded copper, which is a process of placing copper foil directly on alumina or aluminum nitride ceramics in a protective atmosphere, and keeping the temperature at 1065°C for 40-60 minutes. The eutectic reaction between the ceramics forms a transition layer, which is directly bonded to the ceramic surface. This process has fewer steps, can be used as a metal pattern or as a connecting metal, has high bonding strength, large current carrying, and strong solderability. It is the mainstream process for ceramic PCBs. Although this process has many advantages, it can only generate eutectic phases of complex oxides such as cu(alo2)2 and cu(alo2) on the surface of specific types of ceramics (aluminum nitride, alumina), thereby completing direct bonding on the ceramic surface. Combined with copper foil, the process is complicated and the cost is high.

Related Keywords