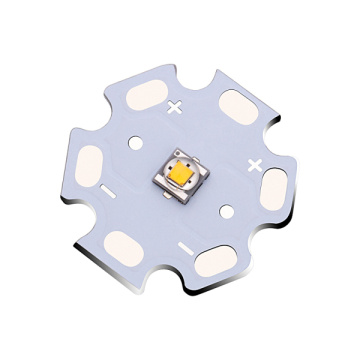

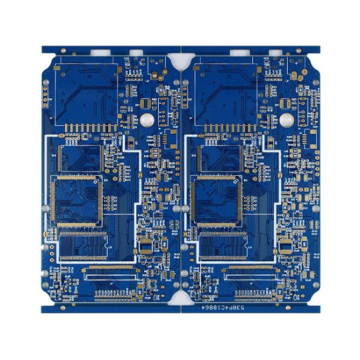

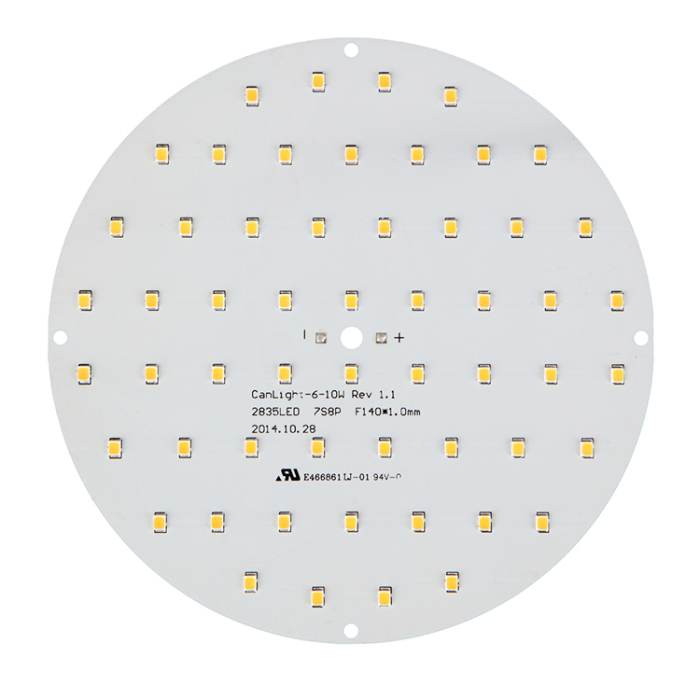

94v0 aluminum light led bulb pcb

-

$0.01≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

Product Description

Product Description

How do you solder LED lights to circuit boards?

If a customer wants to offer aluminum PCB fabrication services, in order to reduce production costs, the production process does not go through the Wave Solder for PCBA method, but uses the heating table method:

1. Turn on the heating table, adjust the temperature, and set the temperature to about 260 degrees. The temperature can be adjusted appropriately according to the size and material of the PCB.

2. After applying solder paste on a pcb board, place it on the heating table for soldering. Seeing that the tin melts, use tweezers to adjust the lamp beads that are not in the silk screen to within the silk screen.

3. After soldering, put the PCBA in a place where it is easy to dissipate heat to make it cool quickly.

4. It is easy to use the lamp bead test to test whether the lamp bead is well welded.

1. Turn on the heating table, adjust the temperature, and set the temperature to about 260 degrees. The temperature can be adjusted appropriately according to the size and material of the PCB.

2. After applying solder paste on a pcb board, place it on the heating table for soldering. Seeing that the tin melts, use tweezers to adjust the lamp beads that are not in the silk screen to within the silk screen.

3. After soldering, put the PCBA in a place where it is easy to dissipate heat to make it cool quickly.

4. It is easy to use the lamp bead test to test whether the lamp bead is well welded.

Related Keywords

Related Keywords