Factory Of Origincheap custom pcb fabrication

-

$0.21≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express, Others

- Port:

- shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 10000pcs/day |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,EXW |

| Transportation: | Ocean,Land,Air,Express,Others |

| Port: | shenzhen |

How can I make PCB cheaper?

As a hardware designer, the job is to develop PCBs on time and within budget, and they need to be able to work normally! In this article, I will explain how to consider the manufacturing issues of the circuit board in the design, so that the cost of the circuit board is lower without affecting the performance. Please keep in mind that many of the following techniques may not meet your actual needs, but if circumstances permit, they are a good way to reduce costs.

If there is enough space available, all SMT components can be placed on one side of the circuit board. In this way, the circuit board only needs to go through the SMT manufacturing process once. If there are components on both sides of the circuit board, it must go through twice. By eliminating the second SMT run, manufacturing time and PCBA Manufacturing can be saved.

Although this will not save any actual manufacturing costs, even if the replaceable parts are out of stock, there is no need to redesign and redesign the circuit board. As most engineers know, it is in everyone's best interest to avoid redesigning!

Here are some tips for selecting easy-to-replace parts:

1. Choose parts with standard dimensions to avoid the need to change the design every time the part becomes obsolete. If the replacement product has the same footprint, you only need to replace a new part to complete!

2. Before selecting components, please visit some manufacturer's websites to see if any components are marked as "obsolete" or "not recommended for new designs".

Choosing smaller components can save valuable board space, but this design choice has a drawback. They require more time and effort to be placed and placed correctly. This leads to higher manufacturing costs.

It's like an archer who shoots an arrow at a target that is 10 feet wide and can hit it without having to concentrate too much. Archers can shoot continuously without losing too much time and energy. However, if your target is reduced to only 6 inches, then the archer must concentrate and spend a certain amount of time in order to hit the target correctly. Therefore, parts smaller than 0402 require more time and effort to complete the installation, which means that the cost will be higher.

Four, understand and follow the manufacturer's production standards

Follow the standards given by the manufacturer. Will keep the cost low. Complex projects usually cost more to manufacture.

When designing a project, you need to understand the following points:

● Use a standard stack with standard materials.

● Try to use 2-4 layers of PCB.

● Keep the minimum trace/gap spacing within the standard spacing.

● Avoid adding special requirements as much as possible.

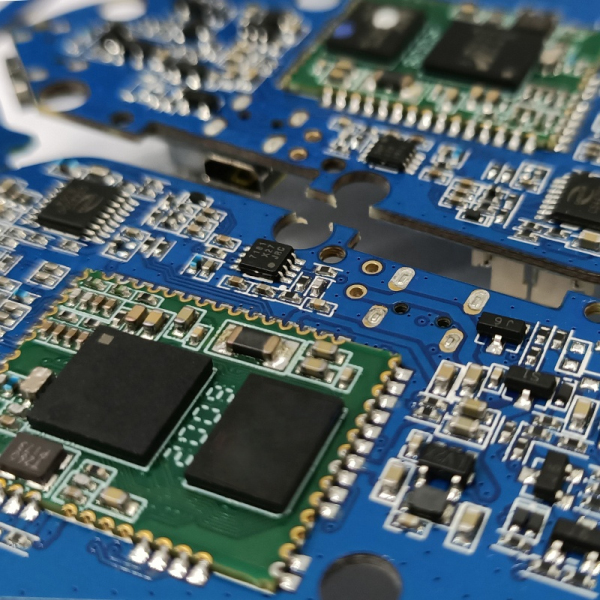

5. Try to use surface mount and assembly (Surface-Mount (SMT) &BGA Assembly)

Use SMT components instead of through holes whenever possible. This will not only reduce the cost of making circuit boards, but also reduce delivery time. SMT and communication PCB components are almost completely regarded as independent manufacturing processes.

Therefore, if all SMT components can be used in the entire design, the entire communication PCB manufacturing process will be eliminated. Of course, this may not be possible, but it is worth trying.

This method has two issues that need attention:

1. Not all equivalent SMT and through-hole Electronic Components are priced the same. Sometimes, the cost of SMT components is higher, so the cost of manufacturing savings must be weighed against the cost difference of the part price.

2. If you want to replace through-hole Cable Connectors I/O Connectors with equivalent SMT, pay attention to whether someone will deal with the connectors regularly. SMT parts do not have the mechanical strength of their communication PCB similar parts, and generally cannot withstand the same amount of wear.

Follow the above suggestions to design, you can reduce the manufacturing cost of your PCB project, but maintain the same performance.

Related Keywords