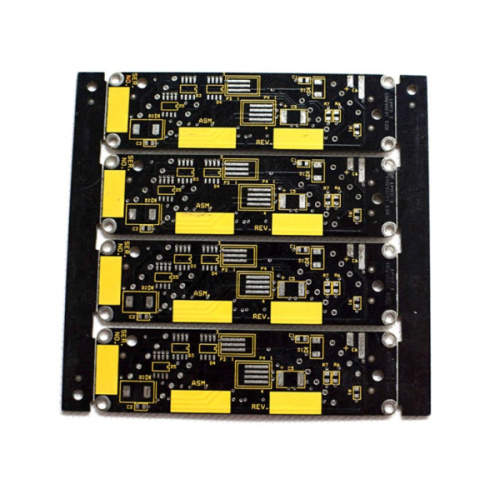

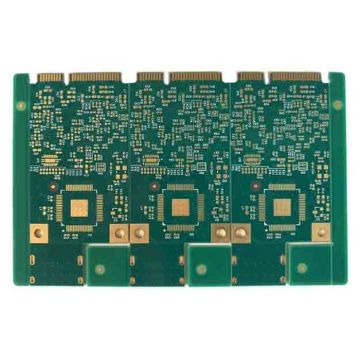

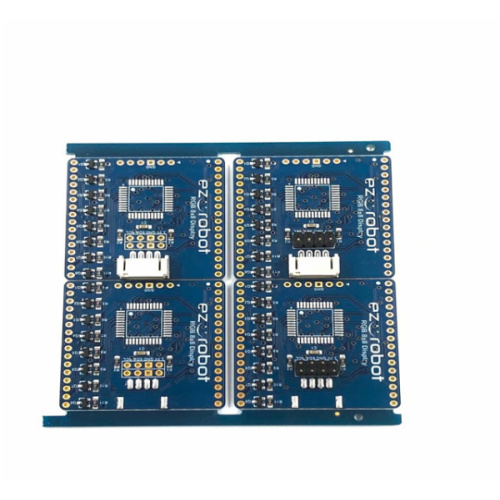

Double-sided HASL 94v0 circuit board pcb factory

-

$0.09≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express, Others

- Port:

- shenzhen

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 10000pcs/day |

|---|---|

| Payment Type: | T/T,Paypal,Others |

| Incoterm: | FOB,EXW |

| HS Code: | 853400 |

| Transportation: | Ocean,Land,Air,Express,Others |

| Port: | shenzhen |

Product Description

Product Description

How much does PCB printing cost?

In custom pcb fabrication, the main factors affecting the cost are the following four points

1. PCB layers

Generally, the more PCB layers with the same area, the higher the price. The design engineer should use a small number of layers to complete the PCB design while ensuring the High Quality Prototype PCB Fabrication of the design signal.

2. PCB size

With a certain number of layers, the smaller the size of the PCB, the lower the price. The design engineer will not affect the electrical performance when designing the PCB. If the size of the PCB can be reduced, the size can be reduced reasonably and the custom circuit board cost manufacturing can be reduced.

3. Easy to make

The main parameters that affect PCB manufacturing are the minimum line width, minimum line spacing, minimum punching, etc. If these parameters are set too small or the process capability has reached the minimum limit of the PCB factory, the yield of PCB will be reduced and the production cost will increase. . Therefore, when designing the PCB process, avoid challenging the limits of the factory, set reasonable line width and line spacing, and punch holes. Similarly, through holes can be designed, try not to use HDI blind holes, because the processing process of blind via hole PCB is much more difficult than through holes, which will increase the production cost of PCB.

4. PCB board material

There are many types of PCB boards, such as common paper-based printed circuit boards, epoxy fiberglass cloth printed circuit rice composite substrate printed circuit boards, Flame resistant PCB, special substrate printed circuit boards, Aluminum base board. The processing gap of different materials is very large, and the processing cycle of some special materials will be longer. Therefore, when designing, it is necessary to select as much as possible the more common and affordable materials that meet the design requirements, such as RF4 materials.

Related Keywords

Related Keywords