Current and line width in PCB design

-

$2.00≥2 Piece/Pieces

- Min. Order:

- 2 Piece/Pieces

- Min. Order:

- 2 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express, Others

- Port:

- shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | T/T,Paypal |

|---|---|

| Incoterm: | FOB,EXW,FCA |

| Transportation: | Ocean,Land,Air,Express,Others |

| Port: | shenzhen |

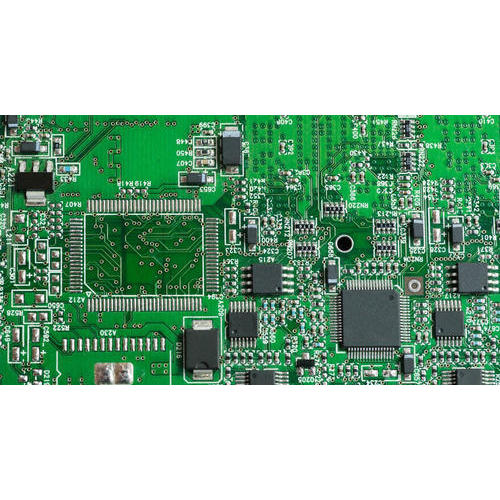

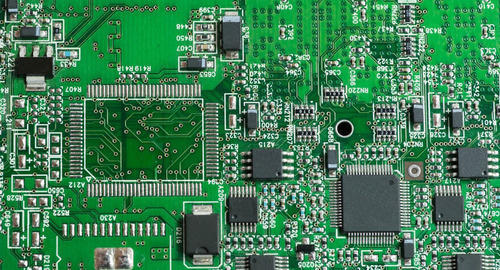

What's the relationship between current and line width in PCB design?

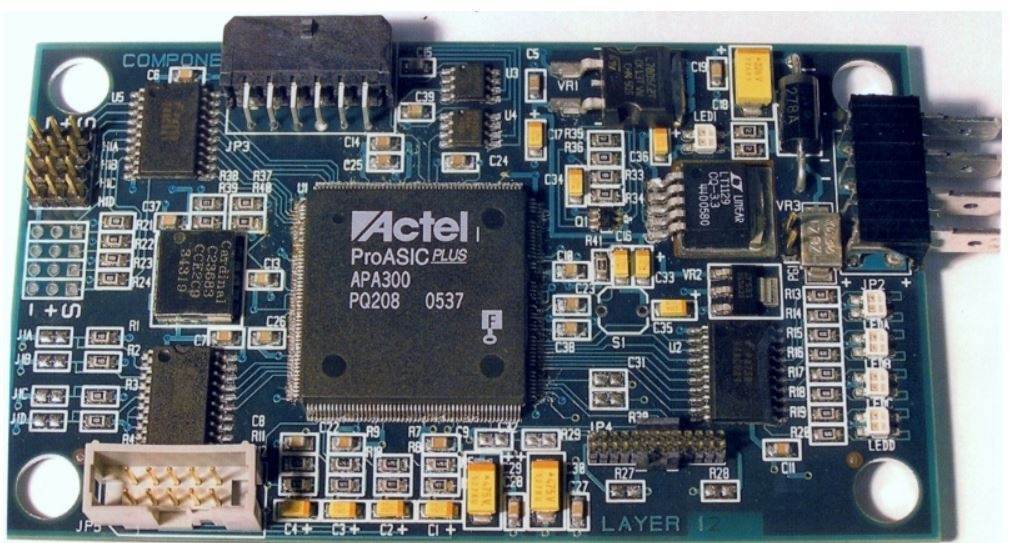

PCB design copper platinum thickness, line width and current relationship

Before understanding the relationship between PCB design copper platinum thickness, line width and current, let us first understand the conversion between ounces, inches and millimeters of PCB copper thickness: "In many data sheets, PCB copper thickness is often used in ounces. As a unit, its conversion relationship with inches and millimeters is as follows:

1 ounce = 0.0014 inches = 0.0356 millimeters (mm)

2 ounces = 0.0028 inches = 0.0712 millimeters (mm)

Ounce is a unit of weight, and the reason why it can be converted to millimeters is because the thickness of the copper coating of the PCB is ounces/square inch"

You can also use the empirical formula to calculate: 0.15 × line width (W) = A

The above data are all line current carrying values at a temperature of 25°C.

Wire impedance: 0.0005×L/W (line length/line width)

In addition, the relationship between the current carrying value of the wire and the number of vias pads of the wire

There is a direct relationship between the current carrying value of the wire and the number of vias on the wire.

In the actual design, various factors such as the environment, manufacturing process, sheet technology, sheet quality, etc. must also be considered. In the actual design, each wire will also be affected by the pads and vias. For example, the line segment with a lot of pads, after tinning, the current carrying value of the pad section will greatly increase, and there may be many people I have seen that a certain section of the line between the pad and the pad in some high-current boards is burned. The reason is very simple. The pad has component feet and solder to enhance the current carrying value of that section of the wire after the soldering is completed. , And the maximum current carrying value of the pad between the pad and the pad is also the maximum current carrying value allowed by the wire width. Therefore, when the circuit fluctuates momentarily, it is easy to burn the section of the line between the pad and the pad. The solution: increase the width of the wire. A wire of about 0.6 Solder layer can be added to the wire, of course, you also add a 1mm Solder layer wire) So after tinning, this 1mm wire can be regarded as a 1.5mm~2mm wire (depending on the wire) The uniformity and amount of tin when tin is passed)

Related Keywords