Durable Screw Compressor Parts - Compression Line Filter

-

$236.001-49 Piece/Pieces

-

$100.00≥50 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- YANTIAN, SHEKOU, QINGDAO

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 500pcs per day |

| Supply Ability: | 500PCS PER DAY |

| Payment Type: | T/T |

| Incoterm: | EXW |

| HS Code: | 8421399090 |

| Transportation: | Ocean,Land,Air |

| Port: | YANTIAN,SHEKOU,QINGDAO |

Product Description

Product Description

Do you know how important of compressed air filter?

Here is several function of compressed air filter you have to know.

1. Purify the air and remove impurities: The filter can effectively remove dust, particulate matter, oil mist and other impurities in the compressed air. If these impurities enter the system, they will pollute the equipment, affect product quality, and even cause equipment failure and increase maintenance costs. Through the fine filtration of the filter, the cleanliness of the compressed air can be ensured, and high-quality air can be provided to the system;

2. Protect equipment and reduce wear: While purifying the air, the filter is also silently protecting the equipment inside the system. For example, the air compressor is the core component of the compressed air system, and its internal precision parts have extremely high requirements for air quality. If there are impurities in the air, these impurities will accumulate inside the compressor, accelerate the wear of parts, and reduce equipment performance. The existence of the filter can effectively prevent this from happening and extend the service life of the equipment;

3. Improve efficiency and save energy: The filter can reduce the obstruction of impurities in the air to the flow of the system, allowing the air to flow more smoothly, thereby improving the operating efficiency of the system. At the same time, the smoother operation of the system can also save energy to a certain extent and reduce operating costs;

4. Reduce maintenance costs: The filter can reduce the failure rate of equipment and reduce maintenance costs. During the operation of pneumatic equipment, impurities such as oil, water, and dust may cause equipment failure and increase maintenance costs. By using compressed air filters, the equipment failure rate can be reduced, thereby reducing maintenance costs;

5. Ensure product quality: In the production process of food, medicine, etc., there are high requirements for compressed air quality. Compressed air filters can ensure air quality, avoid pollution caused by impurities, and ensure product quality;

6. Energy saving and environmental protection: Filters can reduce the energy consumption of pneumatic equipment, reduce operating costs, and reduce emissions, which is beneficial to environmental protection.

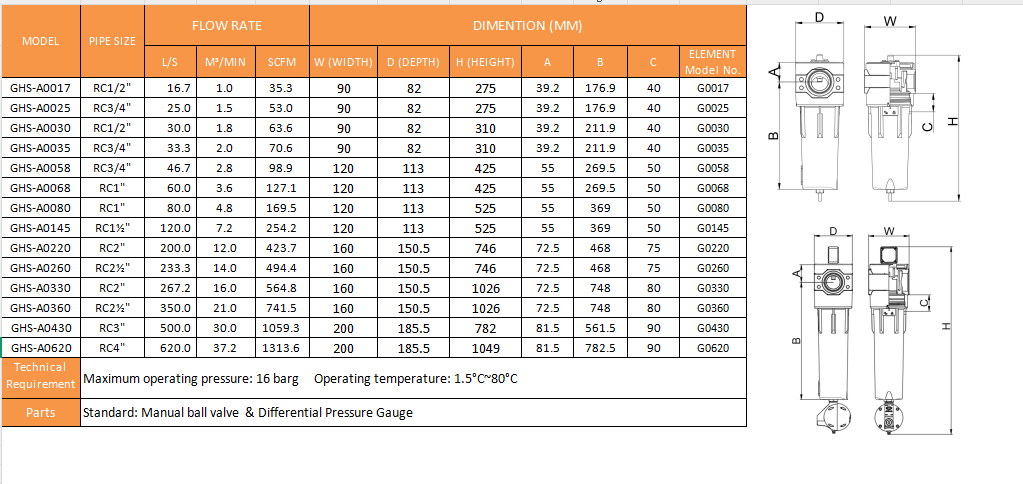

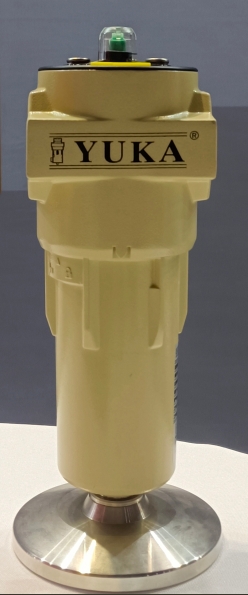

GHS series Compressed Air Filter are design for new automation application, Nitrogen Generator, Oxygen Generater, air compressor, etc. With higher filtration performance which could improve your production for different industries, Choose right compression air filter will help you save money.

SPECIFICATION

Related Keywords

Related Keywords

You May Also Like

You May Also Like