4" Pipeline Air Filter With Floating Drain

-

$1199.861-19 Piece/Pieces

-

$1139.87≥20 Piece/Pieces

- Transportation:

- Land, Ocean, Air, Express, Others

- Port:

- Shenzhen, Guangzhou , Shanghai

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | CHINA |

|---|---|

| Productivity: | 500pcs per day |

| Supply Ability: | 500PCS Per Days |

| Payment Type: | T/T,L/C |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | CE |

| HS Code: | 8421399090 |

| Transportation: | Land,Ocean,Air,Express,Others |

| Port: | Shenzhen,Guangzhou ,Shanghai |

Product Description

Product Description

YUKA Aluminum Air Filter Selling Point

① 7 Layers for filter element, fiber glass material, PF/AO/AA/AX with 4000-6000 hours spanlife.

② Meet the standard of ISO8573.1-2010Effectively filter solid particles up to 0.01 microns, suspended oil up to 0.001mg/m³.

③ 15 years warranty for air filter case, integrate die-casting technology with aluminum alloy material.

International test and measurement standard ISO12500

>ISO 12500 has made clear a general test and definition method for the Air Compressor Filter manufacturers. The main performance

parameters are the air inlet oil content and particles size distribution of the solid particles.

>ISO12500-1 specifies the test requirements for the filtration performance of oil aerosol in the coalescing filter.

>ISO12500-2 specifies the test requirements of adsorption filters for the removal performance of steam adsorption.

>ISO12500-3 specifies the requirements for removal of particulate matter from solid pullutants.

Product are test with the international advanced testing equipment based on standard ISO12500, Which is equivalent to the standard ISO8573.1-2010 quality standard, and provide filter performance test report.

International test and measurement standard ISO12500

>ISO 12500 has made clear a general test and definition method for the Air Compressor Filter manufacturers. The main performance

parameters are the air inlet oil content and particles size distribution of the solid particles.

>ISO12500-1 specifies the test requirements for the filtration performance of oil aerosol in the coalescing filter.

>ISO12500-2 specifies the test requirements of adsorption filters for the removal performance of steam adsorption.

>ISO12500-3 specifies the requirements for removal of particulate matter from solid pullutants.

Product are test with the international advanced testing equipment based on standard ISO12500, Which is equivalent to the standard ISO8573.1-2010 quality standard, and provide filter performance test report.

| Filtration Grade | PF | AO | AA | AX | ACS | AR | AAR |

| Size of solid particles(ISO12500-3) | 5μm | 1μm | 0.01μm | 0.01μm | - | 1μm | 0.01μm |

| Filtration performance of solid particles(ISO12500-3) | - | 99.999+% | 99.999+% | 99.999+% | 99.999+% | 99.999+% | 99.999+% |

| Filtration performance of oil(ISO12500-1) | 50% | 80+% | 99.9+% | 99.99+% | - | - | - |

| Residual oil content(ISO12500-1) | 5mg/m³ | 0.6mg/m³ | <0.01mg/m³ | <0.001mg/m³ | <0.004mg/m³ | - | - |

Coalescing Air Filter's Feature& Benefit

1. Aluminum Alloy material, 15 years serve life for filter housing under working condition from temperature 1.5ºC~80ºC.Maxi. Pressure is 1.0Mpa.

1. Aluminum Alloy material, 15 years serve life for filter housing under working condition from temperature 1.5ºC~80ºC.Maxi. Pressure is 1.0Mpa.

2. 6000~8000 hours serve life for filter element,filtering performance up to 99%

3. Integrated die-casting filter up to 4 inch, flow rate up to 48m³/min.

4. Top cap of filter element with diversion fins, which will let the air come inside the filter more smooth, less pressure loss.

3. Integrated die-casting filter up to 4 inch, flow rate up to 48m³/min.

4. Top cap of filter element with diversion fins, which will let the air come inside the filter more smooth, less pressure loss.

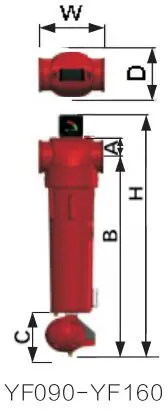

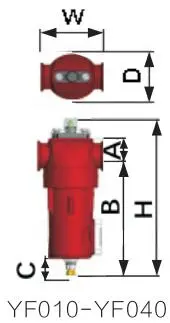

Technical Specification

The flow rate below is the treatment capacity of compressed air under rated working pressure 7 barg (100psi g).

For application in other working pressure, please refer to the correction factors.

| Model | Pipe size | Flow rates | Dimension (mm) | |||||||

| L/S | m3/min | scfm | W(Width) | D(Depth) | H(Height) | A | B | C(clearance for housing) | ||

| YF010 | RC1/2" | 16.7 | 1.0 | 35.3 | 96 | 79 | 261 | 29 | 198 | 118 |

| YF020 | RC3/4" | 25.0 | 1.5 | 53.0 | 96 | 79 | 261 | 29 | 198 | 118 |

| YF030 | RC3/4" | 30.0 | 1.8 | 63.6 | 96 | 79 | 295 | 29 | 233 | 153 |

| YF040 | RC1" | 33.3 | 2.0 | 71.0 | 96 | 79 | 295 | 29 | 233 | 153 |

| YF060 | RC1" | 60.0 | 3.6 | 127.0 | 138 | 111 | 403 | 37 | 296 | 208 |

| YF070 | RC1" | 83.3 | 5.0 | 177.0 | 138 | 111 | 503 | 37 | 396 | 303 |

| YF080 | RC1-1/2" | 125.0 | 7.5 | 265.0 | 138 | 111 | 503 | 37 | 396 | 303 |

| YF090 | RC2" | 166.7 | 10.0 | 353.1 | 174 | 142 | 736 | 58 | 607 | 469 |

| YF100 | RC2-1/2" | 216.7 | 13.0 | 459.0 | 174 | 142 | 736 | 58 | 607 | 469 |

| YF110 | RC2" | 283.3 | 17.0 | 600.0 | 174 | 142 | 1016 | 58 | 887 | 794 |

| YF120 | RC2-1/2" | 316.7 | 19.0 | 671.0 | 174 | 142 | 1016 | 58 | 887 | 794 |

| YF130 | RC3" | 416.7 | 25.0 | 883.0 | 220 | 184 | 793 | 74 | 649 | 514 |

| YF140 | RC4" | 466.7 | 28.0 | 989.0 | 220 | 184 | 793 | 74 | 649 | 514 |

| YF150 | RC3" | 683.3 | 41.0 | 1448.0 | 220 | 184 | 1050 | 74 | 906 | 764 |

| YF160 | RC4" | 800.0 | 48.0 | 1695.0 | 220 | 184 | 1050 | 74 | 906 | 764 |

| Technical requirements | Maximum operating pressure: 10 barg Operating temperature: 1.5°C~80°C. | |||||||||

| Pressure | Barg | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| Psig | 15 | 29 | 44 | 59 | 73 | 87 | 100 | 116 | 131 | 145 | 160 | 174 | 189 | 203 | 219 | 232 | |

| Correction factor | 0.38 | 0.53 | 0.65 | 0.76 | 0.85 | 0.93 | 1.00 | 1.07 | 1.13 | 1.19 | 1.23 | 1.31 | 1.36 | 1.41 | 1.46 | 1.51 | |

Replacements & Spare Parts

Success Cases

Related Keywords

Related Keywords