63.6CFM Activated Carbon Air Filter With Drain

-

$162.601-19 Piece/Pieces

-

$154.46≥20 Piece/Pieces

- Transportation:

- Land, Ocean, Air, Express

- Port:

- Shenzhen, Guangzhou , Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 20,000pcs per month |

| Supply Ability: | 20,000PCS Per Month |

| Payment Type: | T/T,L/C |

| Incoterm: | FOB,CFR,EXW,CIF |

| Certificate: | CE |

| HS Code: | 8421399090 |

| Transportation: | Land,Ocean,Air,Express |

| Port: | Shenzhen,Guangzhou ,Shanghai |

How does Aluminum Air Filter work?

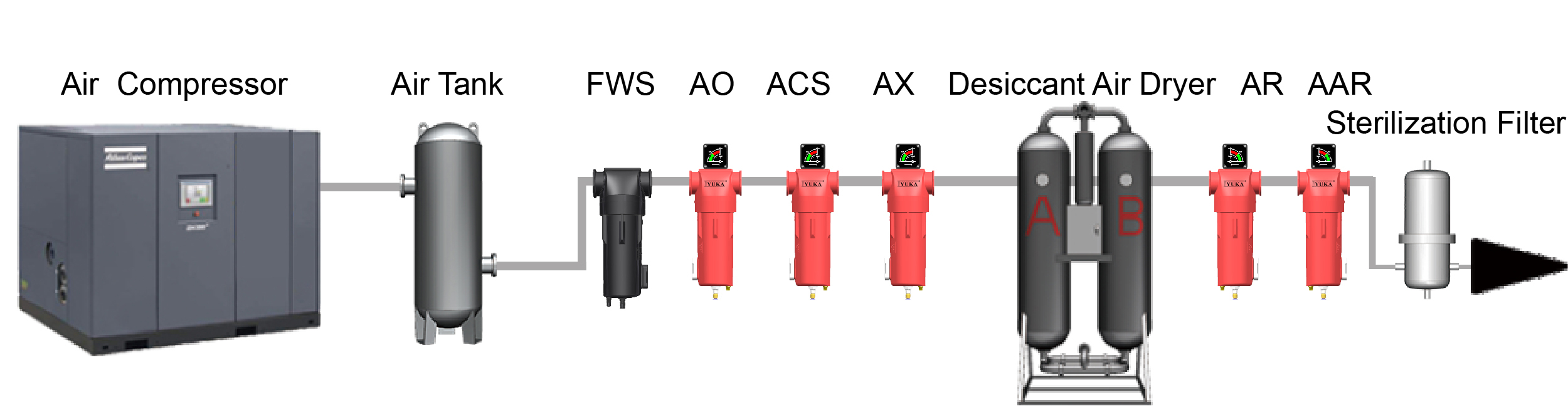

Compressed air systems require clean air to function properly and provide air to applications that does not damage machinery. Properly function air filters consist of pre-filter and after filters:

Pre-filters: These Air Compressor Filter trap and filter the wet, dirty air that enter the air dryer.

After filter: These filters then filter the dryer air as it leave from the dryer

Particulate filters capture debris, oils and other coarse contaminants. The air then enters the coalescing filter, which gets rid of fine impirities like water or oil aerosols. After the air leaves the dryer, it goes through another particulate filter to make sure the air is completely clean.

YF series Coalescing Air Filter is recommended for the industries in automation, cosmetics, blow molding, spraying etc. Feature

1. Aluminum Alloy housing Spanlife : 15 years under working condition from temperature 1.5ºC~80ºC.Maxi. Pressure is 1.0Mpa.

3. Product range: Integrated die-casting filter up to 4 inch, flow rate up to 48m³/min.

4. Top cap of filter element with diversion fins, which will let the air come inside the filter more smooth, less pressure loss.

Technical Specification

The flow rate below is the treatment capacity of compressed air under rated working pressure 7 barg (100psi g).

For application in other working pressure, please refer to the correction factors.

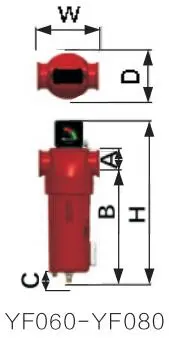

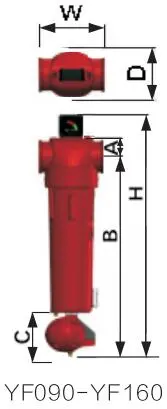

| Model | Pipe size | Flow rates | Dimension (mm) | |||||||

| L/S | m³/min | scfm | W(Width) | D(Depth) | H(Height) | A | B | C(clearance for housing) | ||

| YF010 | RC1/2" | 16.7 | 1.0 | 35.3 | 96 | 79 | 261 | 29 | 198 | 118 |

| YF020 | RC3/4" | 25.0 | 1.5 | 53.0 | 96 | 79 | 261 | 29 | 198 | 118 |

| YF030 | RC3/4" | 30.0 | 1.8 | 63.6 | 96 | 79 | 295 | 29 | 233 | 153 |

| YF040 | RC1" | 33.3 | 2.0 | 71.0 | 96 | 79 | 295 | 29 | 233 | 153 |

| YF060 | RC1" | 60.0 | 3.6 | 127.0 | 138 | 111 | 403 | 37 | 296 | 208 |

| YF070 | RC1" | 83.3 | 5.0 | 177.0 | 138 | 111 | 503 | 37 | 396 | 303 |

| YF080 | RC1-1/2" | 125.0 | 7.5 | 265.0 | 138 | 111 | 503 | 37 | 396 | 303 |

| YF090 | RC2" | 166.7 | 10.0 | 353.1 | 174 | 142 | 736 | 58 | 607 | 469 |

| YF100 | RC2-1/2" | 216.7 | 13.0 | 459.0 | 174 | 142 | 736 | 58 | 607 | 469 |

| YF110 | RC2" | 283.3 | 17.0 | 600.0 | 174 | 142 | 1016 | 58 | 887 | 794 |

| YF120 | RC2-1/2" | 316.7 | 19.0 | 671.0 | 174 | 142 | 1016 | 58 | 887 | 794 |

| YF130 | RC3" | 416.7 | 25.0 | 883.0 | 220 | 184 | 793 | 74 | 649 | 514 |

| YF140 | RC4" | 466.7 | 28.0 | 989.0 | 220 | 184 | 793 | 74 | 649 | 514 |

| YF150 | RC3" | 683.3 | 41.0 | 1448.0 | 220 | 184 | 1050 | 74 | 906 | 764 |

| YF160 | RC4" | 800.0 | 48.0 | 1695.0 | 220 | 184 | 1050 | 74 | 906 | 764 |

| Technical requirements | Maximum operating pressure: 10 barg Operating temperature: 1.5°C~80°C. | |||||||||

| Pressure | Barg | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| Psig | 15 | 29 | 44 | 59 | 73 | 87 | 100 | 116 | 131 | 145 | 160 | 174 | 189 | 203 | 219 | 232 | |

| Correction factor | 0.38 | 0.53 | 0.65 | 0.76 | 0.85 | 0.93 | 1.00 | 1.07 | 1.13 | 1.19 | 1.23 | 1.31 | 1.36 | 1.41 | 1.46 | 1.51 | |

Accessories

Related Keywords