Compressed Air Filter With Floating Drain

-

$449.111-19 Piece/Pieces

-

$426.66≥20 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou , Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 20,000pcs per Month |

| Supply Ability: | 20,000PCS Per Month |

| Payment Type: | T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | CE |

| HS Code: | 8421399090 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou ,Shanghai |

Efficient air filtration is the cornerstone of any industrial operation, and our Coalescing Compressed Air Filter stands as a testament to this necessity. Designed for precision and reliability, this filter ensures that your compressed air systems remain free from contaminants, delivering clean and dry air consistently.

Our Compressed Air Dryers And Aluminum Air Filter are engineered with advanced technology to handle a variety of applications, from manufacturing to pharmaceuticals. The Air Compressor Filtration System we offer is tailored to meet the demands of modern industries, providing a comprehensive solution for air purification.

This product line encompasses a range of solutions including coalescing filters, which trap minute particles and oil droplets, ensuring the highest quality of compressed air. The Compressed Air Dryers And Filters in our portfolio are equipped with state-of-the-art desiccant or refrigeration technologies, offering unparalleled performance in moisture removal. The Air Compressor Filtration System integrates seamlessly with existing infrastructure, enhancing efficiency while minimizing downtime.

Key features of our Coalescing Air Filter include multi-stage filtration, corrosion-resistant materials, and easy maintenance access.

The Compressed Air Dryers And Filters boast energy-efficient designs, rapid cycle times, and user-friendly controls.

The Air Compressor Filtration System offers customizable configurations, durable construction, and a low total cost of ownership.

These products are built to withstand rigorous operational conditions, ensuring longevity and consistent performance.

Our Air Compressor Filter is designed to optimize air quality by removing liquid aerosols and particulates down to sub-micron levels. It employs a highly efficient coalescing medium that captures even the finest contaminants, preventing damage to downstream equipment.

The Compressed Air Dryers And Filters utilize advanced desiccant beds or heat exchangers to achieve dew point suppression, protecting sensitive processes and components. The Air Compressor Filtration System combines multiple filtration stages with drying capabilities, delivering air purity levels suitable for critical applications such as food processing and electronics manufacturing.

The ideal use case for our Coalescing Compressed Air Filter arises in environments where air cleanliness is paramount, such as automotive assembly lines or medical facilities. The Compressed Air Dryers And Filters find their application in scenarios requiring consistent moisture control, like paint spraying operations or laboratory settings. The Air Compressor Filtration System is particularly beneficial in large-scale industrial plants where multiple compressors are employed, providing centralized air treatment solutions.

User reviews highlight the robustness and effectiveness of these filtration systems. Many operators praise the ease of installation and maintenance, noting significant improvements in system reliability and reduced operating costs. Testimonials also emphasize the durability of the materials used, which contribute to extended service life and minimal wear over time.

Frequently asked questions often revolve around the maintenance intervals of these systems. Users inquire about the optimal cleaning frequency for coalescing filters and the replacement schedule for dryer cartridges. Another common query pertains to the noise reduction capabilities of the Air Compressor Filtration System, with users seeking assurance that it will not disturb workplace acoustics. Additionally, there is interest in the compatibility of these products with various compressor brands and models.

Feature & Benefit

15 Year spanlife: Aluminum Alloy materia under working condition from temperature 1.5ºC~80ºC.Maxi. Pressure is 1.0Mpa.

6000~8000 hours serve life for filter element,filtering performance up to 99.99%

Integrated die-casting filter up to 4 inch, flow rate up to 48m³/min.

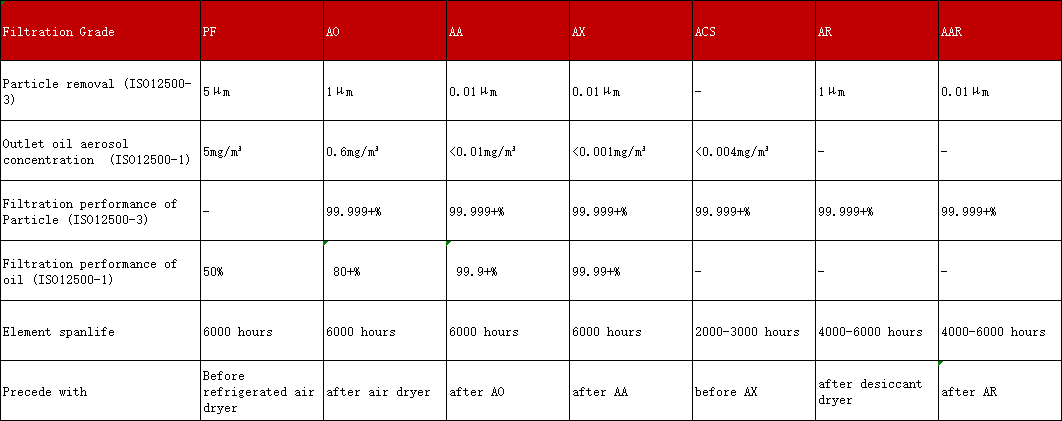

Product are test with the international advanced testing equipment based on standard ISO12500, Which is equivalent to the standard ISO8573.1-2010 quality standard, and provide filter performance test report.

Technical Specification

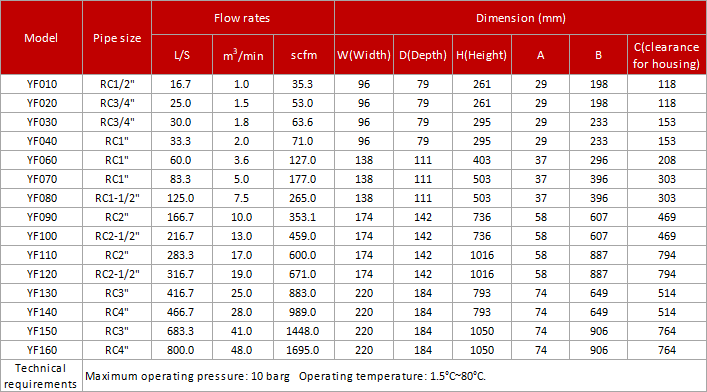

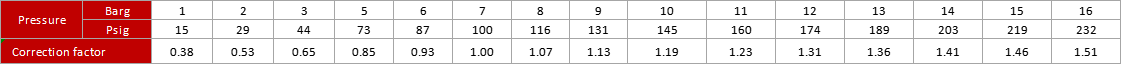

The flow rate below is the treatment capacity of compressed air under rated working pressure 7 barg (100psi g).

For application in other working pressure, please refer to the correction factors.

Accessories

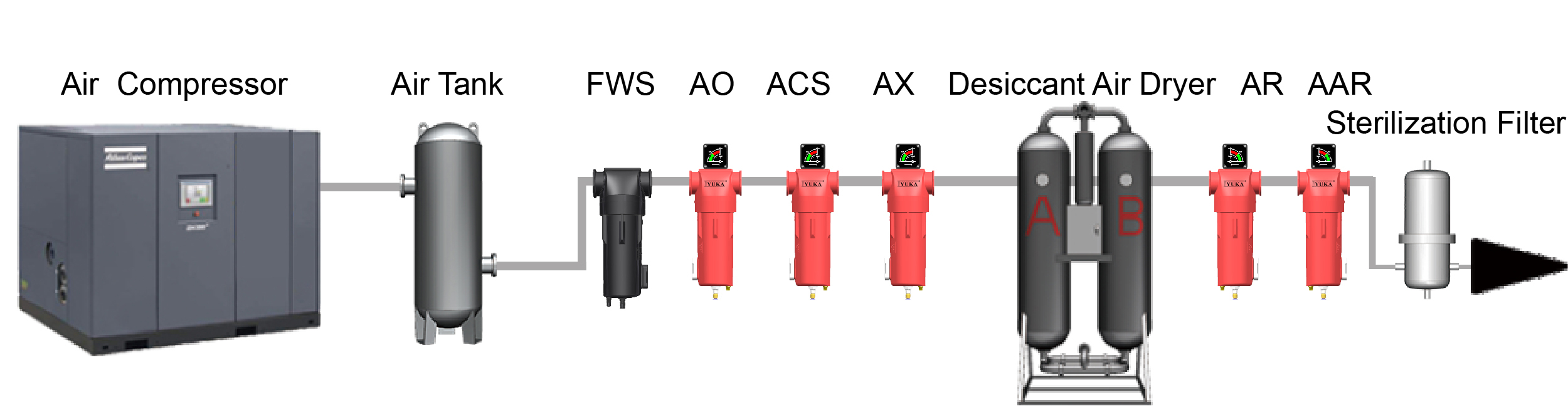

Compressed Air Solution

Related Keywords