Coalescer Filter Cartridge For Air Compressor

-

$69.221-19 Piece/Pieces

-

$65.76≥20 Piece/Pieces

- Transportation:

- Land, Ocean, Air, Express

- Port:

- Shenzhen, Guangzhou, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 500PCS Per Days |

|---|---|

| Payment Type: | T/T,L/C |

| Incoterm: | CIF,EXW,CFR,FOB |

| Transportation: | Land,Ocean,Air,Express |

| Port: | Shenzhen,Guangzhou,Shanghai |

Why are pneumatic system filters required?

In one cubic foot of atmospheric air, there are millions of particles that are potentially harmful to your machines and equipment.

The concentrated contaminates will easily find their way into your process lines, causing frequent and expensive downtime of your pneumatic equipment or adversely affecting the quality of your products. The incorporation of Activated Carbon Filter into your compressed air system will produce benefits in both productivity and product quality.

Feature & Benefit

Operating pressure: 1.6Mpa

Flow rate: 1.0 to 7.2m³/min (till now)

Filtration Rate: 5μm/1μm/0.1μm/0.01μm

Material: Aluminum alloy

Unique lock design,to ensure easy for maintenance and air tightness.

Parallel and wall connection kit available.

High Efficiency Removal of Pollutant

Our Medium & high pressure filter features efficiency fiber glass and felt media to maximize the filtration of dry and wet dust, particulates, oil suspended solids and water droplets. Minimize pressured drop and maintain economical operation costs.

Superior Air Tightness

Unique lock design,easy to replace and maintenance

Avoid Second Pollution

Inside and outside with anti-corrosion, with stainless steel manual ball valve.

Low Differential Pressure

The optimized flow design and the use of filter materials serve to keep differential pressure at a constant low level during the entire service life of the element without compromising it's dirt holding capacity.

High-tech design

It is clearly visible due to the edges at the filter head of the compressed air inlet to ensure reliable connection between the left and right filter housings and the left and right filter housing parts during the assembly process.

Compressed air provides a smooth, non-turbulent air velocity when entering the filter element.

| PF | AO | AA | AX | ACS | AR | AAR |

| As a primary filter, particles whose diameter more than 5μm can be remove,the maxi. residual oil content is negligible | High efficiency general protection, dust particles, water mist & oil mist whose diameter more than 1μm can be removed, the residual content of oil mist does not exceed 0.6mg/m³ (21℃),1ppm(w). | High effiency oil remove filtration, dust particles, water mist and oil mist whose diameter more than 0.01μm can be removed, the residual content of oil mist does not exceed 0.01mg/m³(21℃),0.01ppm(w) | Ultra-efficient filtration, dust particles, water mist&oil mist whose diameter more than 0.01μm can be removed, the residual content of oil mist does not exceed 0.001mg/m³(21℃),0.001ppm(w) | Dust particles whose diameter more than 0.01μm, oil vapor &odor can be removed, the maxi. resident content of oil vapor does not exceed 0.003mg/m³(21℃),0.003ppm(w) | Dust particles whose diameter more than 1μm can be removed | Dust particles whose diameter more than 0.01μm can be removed |

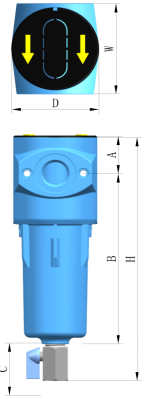

Product Specification

| Model) | Pipe size | Flow rates | Dimension (mm) | ||||||

| L/S | m³/min | scfm | W (Width) | D (Depth) | H (Height) | A | B | ||

| HFD010 | RC1/2" | 16.7 | 1.0 | 35.3 | 90 | 82 | 255 | 37 | 179 |

| HFD020 | RC3/4" | 25.0 | 1.5 | 53.0 | 90 | 82 | 255 | 37 | 179 |

| HFD030 | RC3/4" | 30.0 | 1.8 | 63.6 | 90 | 82 | 286 | 37 | 212 |

| HFD040 | RC1" | 33.3 | 2.0 | 70.6 | 90 | 82 | 286 | 37 | 212 |

| HFD050 | RC3/4" | 46.7 | 2.8 | 98.9 | 120 | 113 | 359 | 53 | 269 |

| HFD060 | RC1" | 60.0 | 3.6 | 127.1 | 120 | 113 | 359 | 53 | 269 |

| HFD070 | RC1" | 80.0 | 4.8 | 169.5 | 120 | 113 | 459 | 53 | 369 |

| HFD080 | RC1-1/2" | 120.0 | 7.2 | 254.2 | 120 | 113 | 459 | 53 | 369 |

| Technical requirements | Maximum operating pressure: 16 barg Maximum operating temperature: 80°C Minimum operating temperature:1.5°C | ||||||||

| Pressure | Barg | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| Psig | 15 | 29 | 44 | 59 | 73 | 87 | 100 | 116 | 131 | 145 | 160 | 174 | 189 | 203 | 219 | 232 | |

| Correction factor | 0.38 | 0.53 | 0.65 | 0.76 | 0.85 | 0.93 | 1.00 | 1.07 | 1.13 | 1.19 | 1.23 | 1.31 | 1.36 | 1.41 | 1.46 | 1.51 | |

YUKA service:

b. Providing timely feedback on complaints

c. Providing perfect after sales service and warranty

Q:Why choose us?

a. 22 years' practical experiences in R&D and manufacturing Compressed air treatment;

b. Founder of Compressed Air Nation Standard GB/T30475.1-2013 and GB/T30475.2-2013;

c. ISO 9001:2015, CE and product follow ISO8573-1;

d. With Germany Imported high efficiency filtration Test Instrument;

e.All goods had been 100% test before dispatched.

Frequently Asked Questions:

Q1. What kind of your company is it?

We're the manufacturer integrated with R&D, production and sales.

Q2. How about your technical conditions and production capability?

Complete process documents and equipment, mass production.

Q3. What is the delivery time?

Delivery time depends on the order quantity, normally is 3-5 working days after 30% payment.

Q4. Do you have a warranty?

Yes, for filter, it is 1 year normally.

Q5. Can you supply customized product?

Yes, we have a professional technical team to provide you with the best solution and complete production processes and control to provide you with satisfied product.