Compressed Air Filter Regulator Combo

-

$287.381-19 Piece/Pieces

-

$273.00≥20 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- SHENZHEN, GUANGZHOU, SHANGHAI

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 500pcs per day |

| Supply Ability: | 500pcs per day |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF,EXW,CFR |

| Certificate: | CE |

| HS Code: | 8421399090 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | SHENZHEN,GUANGZHOU,SHANGHAI |

Sources of compressed air pollutants

Air compressors suck in and compress a large amount of atmosphere. They continue to fill the system while bringing in extremely small pollutants. These pollutants include: water vapor, atmospheric dirt, dust and pollen particles, oil vapor, and microorganisms.

In addition to the pollutants inhaled from the atmosphere, the air compressor will also mix a small amount of oil into the compressed air flow during the air compression process. This oil may exist in the form of liquid oil, aerosols and oil vapor. It is also worth noting that although so-called oil-free compressors do not directly inject oil into the airflow, they still compress the same contaminated air like an air compressor, so any oil vapor in the surrounding environment will still be affected. It is compressed and enters the downstream system. After the compression stage, the aftercooler cools the air, which can condense any water vapor and mix it into the compressed air stream in the form of liquid water or aerosol.

Why need desiccant air filter?

Air Compressor Filter is essential for any air compressor for many reasons. Providing your pneumatic tools with clean air will extend their lifespan significantly.

When you use a compressor, every cubic foot of air that passes through contains millions of foreign particles, all of which can collect and damage or inhibit your tools. These particles include water droplets, oils, dirt, dust, bacteria and, potentially, pieces of heavy metals, such as lead, mercury and cadmium.

If the air passes through unfiltered, it can cause contamination of the control valves, swell the protective seals and cause premature wear, all potentially leading to equipment failure and increase repaired cost.

By implementing the proper filtration system for protection and purification, you can reduce machine downtime and overall cost, as well as limit the amount of necessary maintenance, repair and energy use. But you also need to maintain the filters for the best results, as clogged or worn filters can cause a significant pressure drop, making your compressor less effective.

Feature & benefit

①Integrated die-casting technology, filter housing with 90 kg.f burst pressure-bearing, enjoy 15 years warranty for filter housing

②High filtration performance. With borosilicate fiber glass material, 96% porosity dirst holding ability. 7 layer design for filter element

③Anti-corrosion treatment for inside and outside, prevent second pollution, decrease maintenance cost for owership

④Low Pressure Drop COntrolled, saving energy and saving money

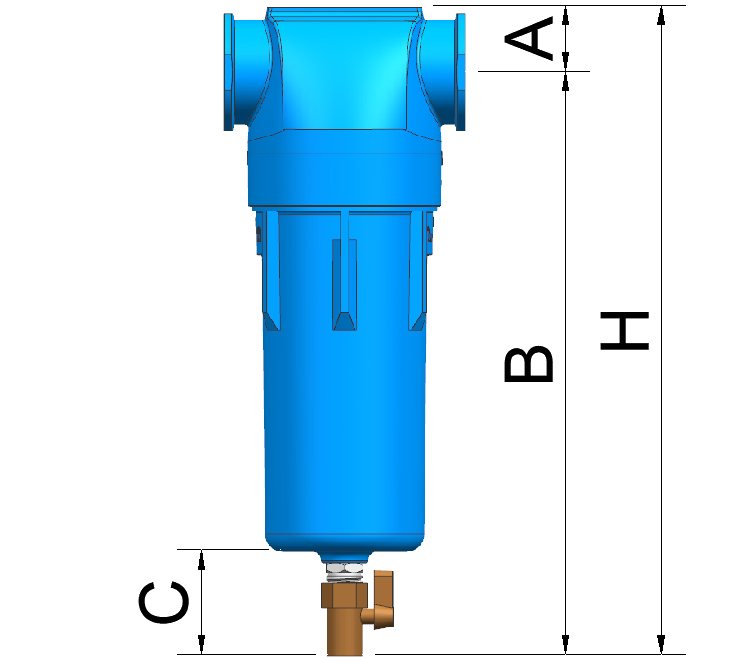

Technical Specification

Model

Pipe size

Flow rates

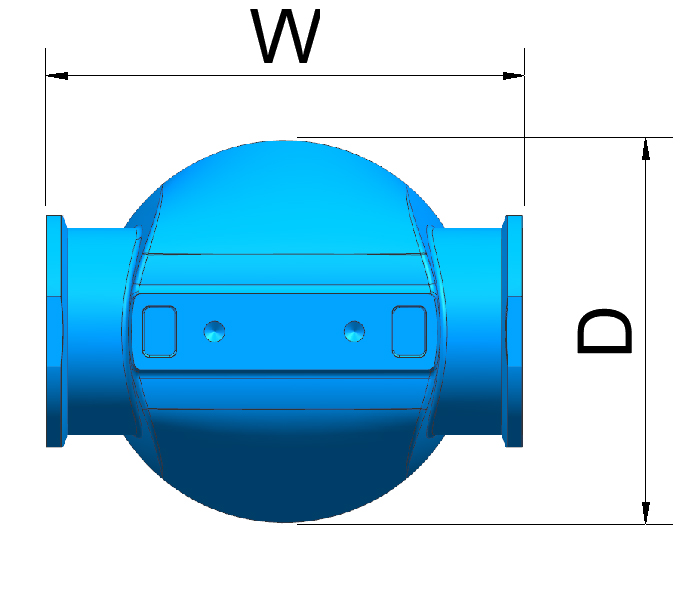

Dimension (mm)

L/S

m³/min

scfm

W (Width)

D (Depth)

H (Height)

A

B

C(clearance for housing)

YFB010

RC1/2"

16.7

1.0

35.5

96

79

252

29

223

118

YFB020

RC3/4"

25.0

1.5

53.0

96

79

252

29

223

118

YFB030

RC3/4"

30.0

1.8

63.6

96

79

286

29

257

153

YFB040

RC1"

33.3

2.0

71.0

96

79

286

29

257

153

YFB060

RC1"

60.0

3.6

127.0

138

111

357

37

320

208

YFB070

RC1"

83.3

5.0

177.0

138

111

458

37

421

303

YFB080

RC1-1/2"

125.0

7.5

265.0

138

111

458

37

421

303

YFB090

RC2"

166.7

10.0

353.1

174

142

558

58

500

467

YFB100

RC2-1/2"

216.7

13.0

459.0

174

142

558

58

500

467

YFB110

RC2"

283.3

17.0

600.0

174

142

838

58

780

794

YFB120

RC2-1/2"

316.7

19.0

671.0

174

142

838

58

780

794

YFB130

RC3"

416.7

25.0

883.0

220

184

645

74

571

514

YFB140

RC4"

466.7

28.0

989.0

220

184

645

74

571

514

YFB150

RC3"

683.3

41.0

1448.0

220

184

902

74

828

764

YFB160

RC4"

800.0

48.0

1695.0

220

184

902

74

828

764

Technical requirements

Maximum operating pressure: 16 barg Maximum operating temperature: 80°C Minimum operating temperature:1.5°C

Pressure

Barg

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Psig

15

29

44

59

73

87

100

116

131

145

160

174

189

203

219

232

Correction factor

0.38

0.53

0.65

0.76

0.85

0.93

1.00

1.07

1.13

1.19

1.23

1.31

1.36

1.41

1.46

1.51

Related Keywords