Remove Particles Dust Oil Aerosol Air Filter

-

$106.571-19 Piece/Pieces

-

$101.24≥20 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- SHENZHEN, GUANGZHOU, SHANGHAI

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 500pcs per day |

| Supply Ability: | 500pcs per day |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF,EXW,CFR |

| Certificate: | CE |

| HS Code: | 8421399090 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | SHENZHEN,GUANGZHOU,SHANGHAI |

How to Install Compressed Air Filter?

1. Clean the compressed air pipes and valves connected to the air inlet and outlet of the filter before installation.

2. Adopt the combination of main pipe filtration and terminal filtration to ensure the gas quality at the point of use.

3. When installing, the air inlet and outlet of the filter should be kept level, and the sewage outlet should be at the bottom. A certain space must be reserved in the vertical direction to facilitate the maintenance of the filter and the replacement of the filter element.

4. The filter of the screw air compressor should be installed in a ventilated and cool place, as close as possible to the air point, to reduce the influence of the pipeline on the quality of the filtered compressed air.

5. Install and use within the specified working pressure and working temperature range, and install all levels of filters in the correct order according to the air inlet and outlet instructions or the direction indicated by the arrow, from coarse to fine installation. Avoid bypass as much as possible during installation. Because the oil in the air is bypassed to the downstream of the filter and then sticks to the inner wall of the pipeline, it is difficult to find effective means to remove it.

YFB Series compressed air filter separator Feature & benefit

①Integrated die-casting technology, filter housing with 90 kg.f burst pressure-bearing, enjoy 15 years warranty for filter housing.

②High filtration performance. With borosilicate fiber glass material, 96% porosity dirst holding ability. 7 layer design for filter element

③Anti-corrosion treatment for inside and outside, prevent second pollution, decrease maintenance cost for owership

④Low Pressure Drop COntrolled, saving energy and saving money.

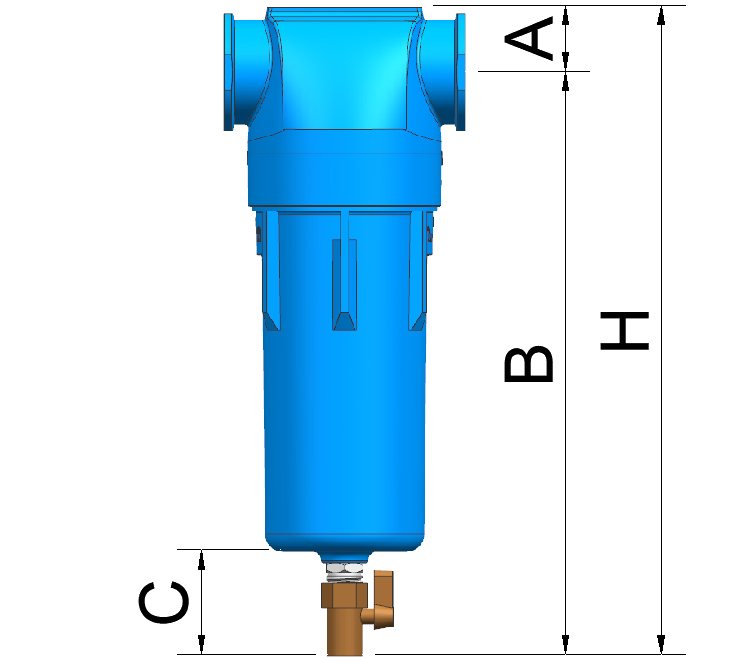

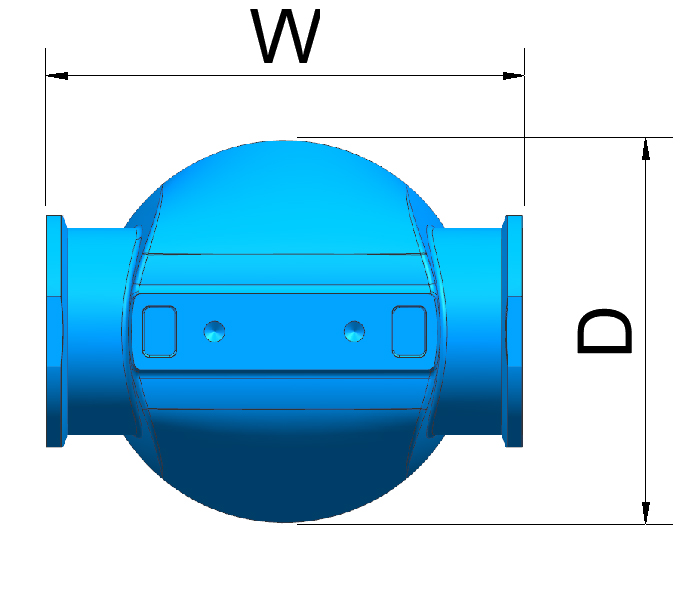

Technical Specification

Model

Pipe size

Flow rates

Dimension (mm)

L/S

m³/min

scfm

W (Width)

D (Depth)

H (Height)

A

B

C(clearance for housing)

YFB010

RC1/2"

16.7

1.0

35.5

96

79

252

29

223

118

YFB020

RC3/4"

25.0

1.5

53.0

96

79

252

29

223

118

YFB030

RC3/4"

30.0

1.8

63.6

96

79

286

29

257

153

YFB040

RC1"

33.3

2.0

71.0

96

79

286

29

257

153

YFB060

RC1"

60.0

3.6

127.0

138

111

357

37

320

208

YFB070

RC1"

83.3

5.0

177.0

138

111

458

37

421

303

YFB080

RC1-1/2"

125.0

7.5

265.0

138

111

458

37

421

303

YFB090

RC2"

166.7

10.0

353.1

174

142

558

58

500

467

YFB100

RC2-1/2"

216.7

13.0

459.0

174

142

558

58

500

467

YFB110

RC2"

283.3

17.0

600.0

174

142

838

58

780

794

YFB120

RC2-1/2"

316.7

19.0

671.0

174

142

838

58

780

794

YFB130

RC3"

416.7

25.0

883.0

220

184

645

74

571

514

YFB140

RC4"

466.7

28.0

989.0

220

184

645

74

571

514

YFB150

RC3"

683.3

41.0

1448.0

220

184

902

74

828

764

YFB160

RC4"

800.0

48.0

1695.0

220

184

902

74

828

764

Technical requirements

Maximum operating pressure: 16 barg Maximum operating temperature: 80°C Minimum operating temperature:1.5°C

Pressure

Barg

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Psig

15

29

44

59

73

87

100

116

131

145

160

174

189

203

219

232

Correction factor

0.38

0.53

0.65

0.76

0.85

0.93

1.00

1.07

1.13

1.19

1.23

1.31

1.36

1.41

1.46

1.51

Related Keywords