Replace Coalescing Air Filter for Compressed Air System

-

$82.501-19 Piece/Pieces

-

$78.38≥20 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- SHENZHEN, GUANGZHOU, SHANGHAI

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 500pcs per day |

| Supply Ability: | 500pcs per day |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF,EXW,CFR |

| Certificate: | CE |

| HS Code: | 8421399090 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | SHENZHEN,GUANGZHOU,SHANGHAI |

What are the benefits of compressed air line filter?

①Improves product quality: If your manufacturing processes require exceptionally clean air, a in line compressed air filter will provide clean air. Aerosols and oil vapors can damage products such as semiconductors or contaminate pharmaceuticals.

②Removes airborne leftovers: In the manufacturing process, airborne leftovers as a result of the process can be potentially harmful to employees and business activities. A filter can remove these airborne filters, making the environment of the facility safer.

③Protects your tools: An air filter can keep your compressed air tools in good working order. Contaminants could damage your tools, causing excessive repairs or early replacement.

An compressed air line water filter is more than an enhancement in an industrial facility — it’s a necessity. Poor air filtration can cause pipe corrosion and pressure drops, as well as cause your compressor to work improperly, leading to higher energy loss, unexpected downtime and expensive repairs. Compressed air particulate filter keeps your compressed air system clean and running well.

YFB Series compressed air filter separator Feature & benefit

①Integrated die-casting technology, filter housing with 90 kg.f burst pressure-bearing, enjoy 15 years warranty for filter housing.

②High filtration performance. With borosilicate fiber glass material, 96% porosity dirst holding ability. 7 layer design for filter element

③Anti-corrosion treatment for inside and outside, prevent second pollution, decrease maintenance cost for owership

④Low Pressure Drop COntrolled, saving energy and saving money.

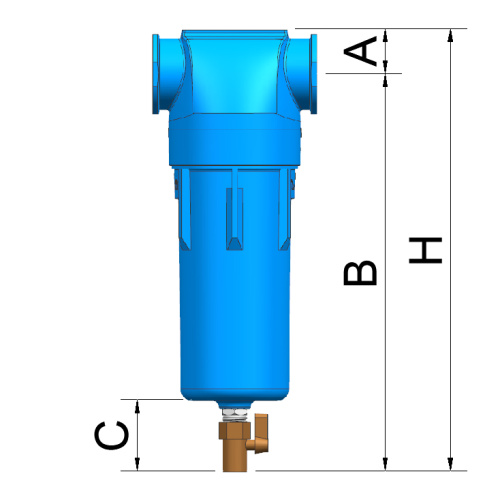

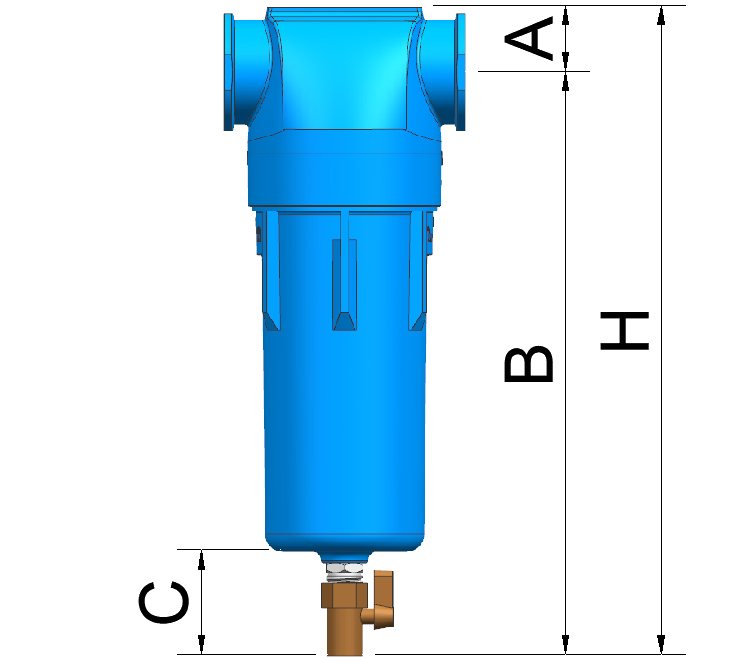

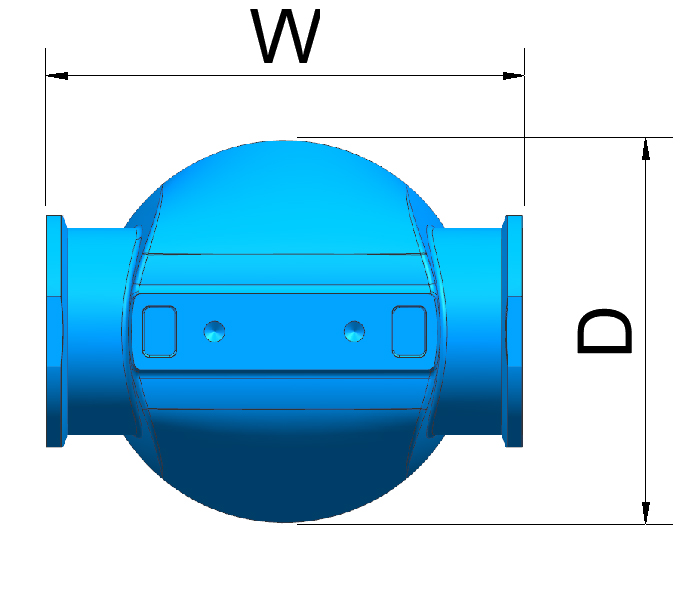

Technical Specification

Model

Pipe size

Flow rates

Dimension (mm)

L/S

m³/min

scfm

W (Width)

D (Depth)

H (Height)

A

B

C(clearance for housing)

YFB010

RC1/2"

16.7

1.0

35.5

96

79

252

29

223

118

YFB020

RC3/4"

25.0

1.5

53.0

96

79

252

29

223

118

YFB030

RC3/4"

30.0

1.8

63.6

96

79

286

29

257

153

YFB040

RC1"

33.3

2.0

71.0

96

79

286

29

257

153

YFB060

RC1"

60.0

3.6

127.0

138

111

357

37

320

208

YFB070

RC1"

83.3

5.0

177.0

138

111

458

37

421

303

YFB080

RC1-1/2"

125.0

7.5

265.0

138

111

458

37

421

303

YFB090

RC2"

166.7

10.0

353.1

174

142

558

58

500

467

YFB100

RC2-1/2"

216.7

13.0

459.0

174

142

558

58

500

467

YFB110

RC2"

283.3

17.0

600.0

174

142

838

58

780

794

YFB120

RC2-1/2"

316.7

19.0

671.0

174

142

838

58

780

794

YFB130

RC3"

416.7

25.0

883.0

220

184

645

74

571

514

YFB140

RC4"

466.7

28.0

989.0

220

184

645

74

571

514

YFB150

RC3"

683.3

41.0

1448.0

220

184

902

74

828

764

YFB160

RC4"

800.0

48.0

1695.0

220

184

902

74

828

764

Technical requirements

Maximum operating pressure: 16 barg Maximum operating temperature: 80°C Minimum operating temperature:1.5°C

Pressure

Barg

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Psig

15

29

44

59

73

87

100

116

131

145

160

174

189

203

219

232

Correction factor

0.38

0.53

0.65

0.76

0.85

0.93

1.00

1.07

1.13

1.19

1.23

1.31

1.36

1.41

1.46

1.51

Related Keywords