Water Separator On Air Compressor

-

$175.001-19 Piece/Pieces

-

$166.25≥20 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 500pcs per day |

| Supply Ability: | 500pcs per day |

| Payment Type: | L/C,T/T |

| Incoterm: | EXW,CIF,CFR,FOB |

| Certificate: | CE |

| HS Code: | 8421399090 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Shanghai |

Where to Install Water Separator On Compressed Air System?

After air compressor, before air receiver, before refrigeration air dryer to install water-gas separator.

The compressed air output from the air compressor contains a lot of harmful substances. If these impurities are not removed by proper methods, it will cause great harm to the air supply system:

>Deteriorated lubricating oil will deteriorate rubber, plastics, and sealing materials, block small holes, and cause valve action to fail.

>Moisture and dust will cause rust and corrosion of metal parts and pipelines, cause blocking or wear of moving parts, and cause malfunction and air leakage of pneumatic components.

>Moisture and dust will also block the throttle orifice or filter: In cold areas, moisture will condense. Ice can cause the pipeline to freeze or crack.

Due to poor air quality, the reliability and service life of the pneumatic system are greatly reduced, and the resulting losses often greatly exceed the cost and maintenance cost of the air source treatment device. Therefore, the correct selection of the air source treatment system is absolutely necessary.

Feature & Benefit & Advantage

> High liquid removal efficiencies at all flow conditions

> Protects coalescing filters from bulk liquid contamination

> Helps provide air quality in accordance with ISO 8573-1:2001 the international standard for compressed air quality

> Suitable for all compressed air applications, Suitable for all compressor types, including variable flow

> Low pressure losses for low operational costs, Low lifetime costs

> All FWS water separators are covered by a 15 year housing guarantee

> Reduce moisture rusting of pipelines and damage to valves, cylinders, electronic components and other equipment

> Protect the filter in front of the dryer and suction dryer

> Efficiently remove liquid in compressed air

> Improve air quality

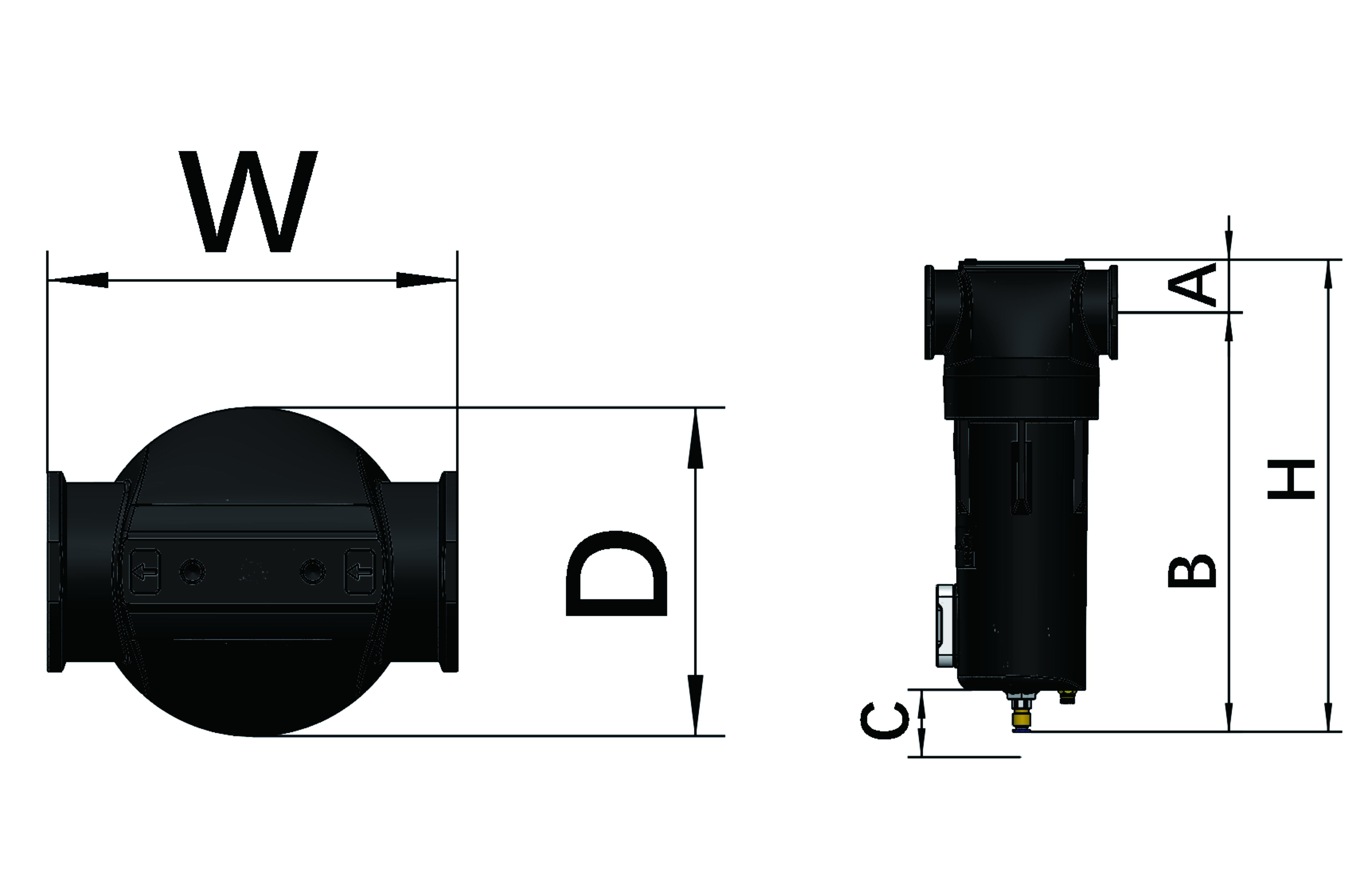

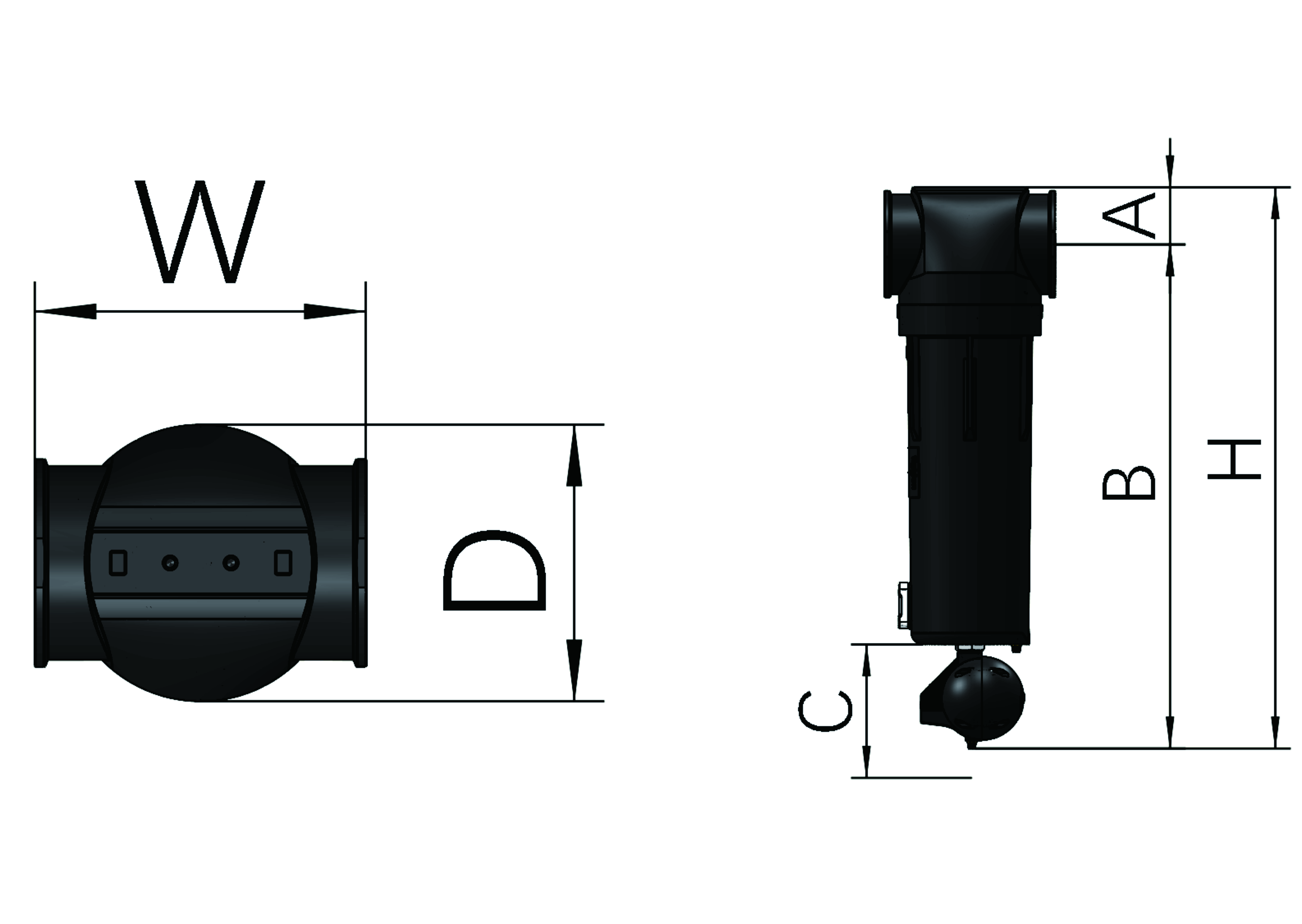

Technical Specification

Model

Pipe size

Flow rates

Dimension (mm)

L/S

m³/min

scfm

W(Width)

D(Depth)

H(Height)

A

B

C (clearance for housing)

FWS010

RC1/2"

40.0

2.4

84.5

96

79

233

29

198

118

FWS020

RC3/4"

60.0

3.6

127.1

96

79

233

29

198

118

FWS050

RC1"

75.0

4.5

158.9

96

79

268

29

233

153

FWS060

RC1"

125.0

7.5

264.8

138

111

339

37

296

208

FWS070

RC1-1/2"

166.7

10.0

353.1

138

111

339

37

296

208

FWS100

RC2"

300.1

18.0

635.6

174

142

669

58

607

469

FWS110

RC2-1/2"

416.8

25.0

882.8

174

142

669

58

607

469

FWS131

RC2-1/2"

700.0

42.0

1483.1

220

184

726

74

649

514

FWS140

RC3"

833.5

50.0

1765.6

220

184

726

74

649

514

FWS140F

DN80/DN100

833.5

50.0

1765.6

300

184

746/761

74

649

514

FWS150

RC4"

1000.2

60.0

2118.7

220

184

726

74

649

514

FWS150F

DN100/DN125

1000.2

60.0

2118.7

300

184

761/776

74

649

514

FWS170

RC4"

1166.7

70.0

2464.0

220

184

983

74

906

764

FWS170F

DN100/DN125

1166.7

70.0

2464.0

300

184

1018/1033

74

906

764

Technical requirements

Maximum operating pressure: 10 barg Operating temperature:1.5~ 80°C

Pressure

Barg

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Psig

15

29

44

59

73

87

100

116

131

145

160

174

189

203

219

232

Correction factor

0.38

0.53

0.65

0.76

0.85

0.93

1.00

1.07

1.13

1.19

1.23

1.31

1.36

1.41

1.46

1.51

Related Keywords