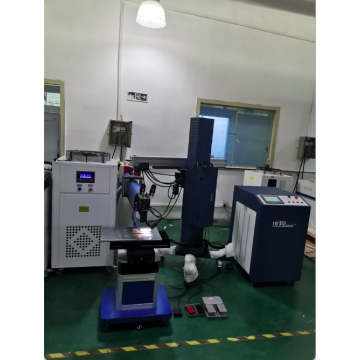

1000 laser welding equipment

-

$8000.00≥4000 Set/Sets

- Min. Order:

- 4000 Set/Sets

- Min. Order:

- 4000 Set/Sets

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | L/C,T/T,D/P,D/A,Paypal |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP |

| Transportation: | Ocean,Land,Air |

Youkonglaser to provide you with High power, high power laser welding machine product detailed parameters, real-time quotes, prices, manufacturers and other information. The welding machine of high-power and high-power fiber laser adopts 1000-3000 watt fiber laser, which has high electro-optic conversion efficiency and long laser life, with a life of 100000 hours. 25% - 30% of the energy provided by the power supply is converted into laser energy, and the photoelectric conversion rate is 10 times higher than that of YAG laser. Intelligent operation: integrated anti-static type of light, machine, water, electricity and gas.

Laser welding equipment Product introduction:

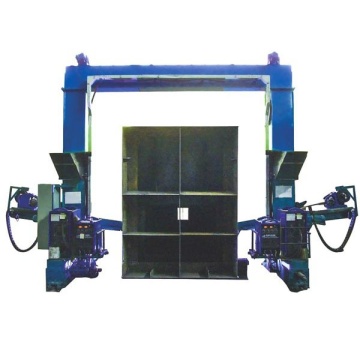

Laser welding production line can realize the welding of many types of materials, and laser welding usually has many incomparable advantages compared with other fusion welding processes, especially can weld thin plate alloy materials, such as aluminum alloy, which are difficult to weld in aviation and automotive industry, and the structure is not deformed, the joint quality is high, and the reproducibility is good. Laser welding production line has become a standard process in the automotive industry. It is used for tailor welding of body panels. Metal plates with different thickness and different surface coating can be welded together and then stamped. The panel structure made in this way can achieve reasonable metal combination.Laser welding equipment System configuration:

Fiber laser, water cooler

Precise positioning table and pressing system

With welding seam tracking and quality inspection system

Loading, unloading and other auxiliary systems

Laser welding equipment Device function:

The automatic laser tailor welding line can automatically complete a series of automatic production processes, such as stack conversion, loading positioning, laser tailor welding, seam tracking, quality detection, finished product sorting, sheet turnover, shallow pit processing, blanking stacking and stacking area automatic selection

Laser welding equipment technological process:

The feeding rotary table rotates to feed, and two pieces of material enter the working area at the same time. Two feeding robots with end pick-up at the end suck up the two pieces of material and place them on the centering clamping table. The pieces of material are positioned, clamped and centered automatically. The laser head moves along the weld line, and the two pieces of material are butt welded at the same time. The side discharge device pulls out the welded steel plate, and the steel plate enters the blanking station. The blanking robot completes the blanking, and places it on the blanking rotary table and palletizes it.

Related Keywords