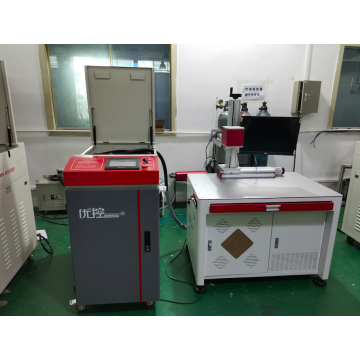

UV laser cutting machine

-

$35000.00≥8000 Set/Sets

- Min. Order:

- 8000 Set/Sets

- Min. Order:

- 8000 Set/Sets

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | L/C,T/T,D/P,D/A |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP |

| Transportation: | Ocean,Land,Air |

Model introduction of UV laser marking machine:

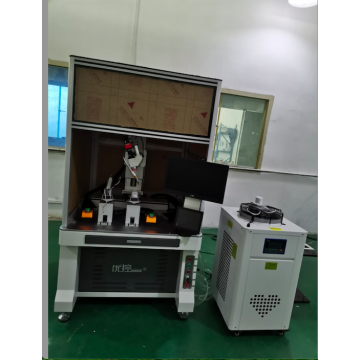

1. The marking range is wide, which can mark all metals and some non metals, and can meet the marking requirements of 95% of users' products.

2. Ultra fine marking, with small aggregation spot and small thermal effect, can carry out ultra-fine marking, which is a choice with higher demand for marking.

3. It is suitable for marking special materials. UV laser marking is cold processing with fine beam, and does not produce heating or thermal deformation on the inner layer and nearby area of the machined surface.

4. The marking effect has high engraving accuracy, and the small line width can reach 0.015mm, which can meet the needs of engraving a large amount of data on small workpieces.

5. The editing and development speed is fast, and the combination of laser technology and computer technology can realize laser printing output as long as programming on the computer, and the marking content can be changed at any time.

The UV laser marking machine is developed by using 355nm UV exciter. The machine adopts third-order intracavity frequency doubling technology. Compared with infrared laser, 355 UV focusing precursor is small, which can greatly reduce the mechanical deformation of materials and has little processing heat impact. However, the material has high absorption rate of 355nm UV light. Therefore, UV laser has wider material adaptability. Because force is mainly used for ultra-fine marking and engraving, it is especially suitable for the marking of food, pharmaceutical packaging materials, microporous, high-speed division of glass materials and complex graphic cutting of silicon wafers.

Main advantages:

Due to the small focusing spot and small processing heat affected zone, UV laser can carry out ultra-fine marking and special material marking. It is a recommended product for customers with higher requirements for marking effect. In addition to copper, UV laser is more suitable for processing materials.

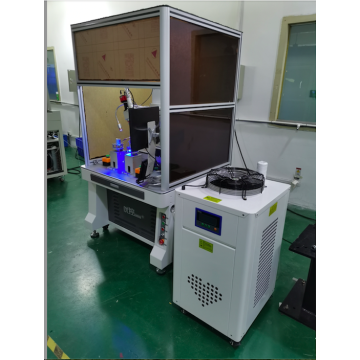

Application scope:

It is mainly used in the market of ultra-fine processing. The surface of packaging bottles of cosmetics, drugs and videos without other polymer materials has fine effect, clear and firm marking, which is better than ink pupil code and no consumables; Marking and scribing of flexible PCB; Micro hole and blind hole processing of silicon wafer; LCD LCD glass two-dimensional code marking, glass appliance surface punching, metal surface transition marking, plastic keys, electronic components, gifts, communication equipment, building materials, etc.

UV laser marking machine is used for fine marking, fine cutting and micro processing of special materials. It is mainly used for marking and surface treatment of various materials such as glass, liquid crystal screen, textiles, thin ceramics, semiconductor silicon wafer, IC grain, sapphire, polymer film and so on.

Sample display

Related Keywords