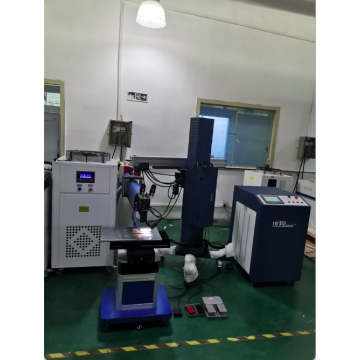

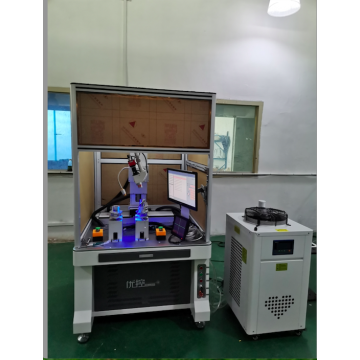

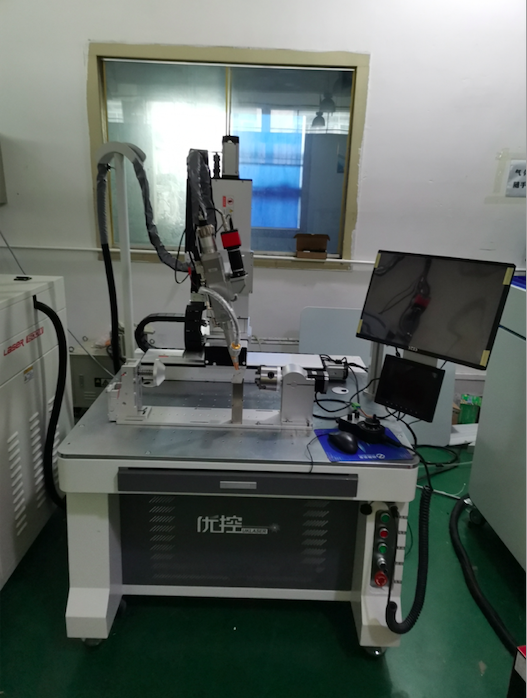

Multifunctional integrated mold laser welder

-

$10000.00≥4000 Set/Sets

- Min. Order:

- 4000 Set/Sets

- Min. Order:

- 4000 Set/Sets

- Transportation:

- Ocean, Land, Express

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | L/C,T/T,D/P,D/A |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP |

| Transportation: | Ocean,Land,Express |

Mold laser welder model features:

1. The mold laser welding machine provides different laser pulse waveform settings. Laser processing parameters with different waveforms can be selected for steel, aluminum and copper to improve the penetration of laser welding and the controllability of the influence of cooling time on the hardness of materials. Archive the preset waveform, so that beginners can also operate conveniently.

2. Mold laser welder system provides up to 50 groups of waveform parameter storage. Because different materials can be welded at any time during mold laser welding, the system parameters can be accessed and used at any time without re editing the waveform, which is convenient and fast.

3. The mold laser welding machine provides the time setting of liquid crystal eye protection gate. For different pulse width, different light blocking time can be set to protect the operator's eyes from the uncomfortable feeling of laser flash.

4. It can set the argon delayed gas closing time after the laser is turned off. This function can effectively protect the welding position during high-power welding, always be protected by argon during cooling, always maintain the primary metal color, and greatly improve the welding quality of high-power laser welding.

Application fields:

The host machine is equipped with manual lifting of laser head and electric lifting of worktable button to realize laser welding of molds with different thickness. This model is more suitable for all kinds of high-power and large-area laser repair molds.

Because of the high laser power, beryllium copper mold, aluminum mold or aluminum parts can be welded by laser at the same time. In large area laser repair mold, thicker welding wire can be used, and the laser welding efficiency can be greatly improved.

Pre sales service

1. Free proofing for customers and help customers overcome process difficulties.

2. Provide customers with technical consulting services free of charge to ensure that the equipment selected by customers can really meet their needs.

Related Keywords