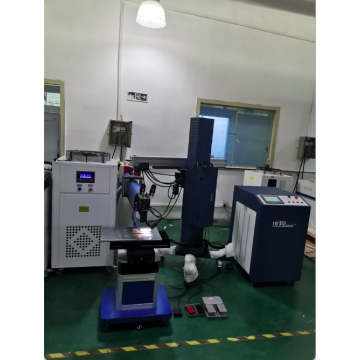

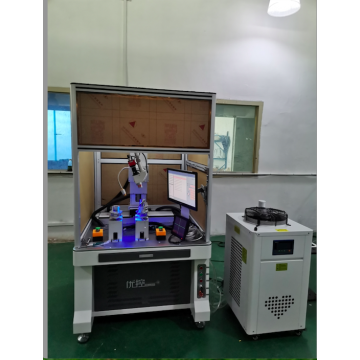

Large mold laser welding machine

-

$10000.00≥4000 Set/Sets

- Min. Order:

- 4000 Set/Sets

- Min. Order:

- 4000 Set/Sets

- Transportation:

- Ocean, Land, Express

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | L/C,T/T,D/P,D/A |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP |

| Transportation: | Ocean,Land,Express |

The laser condensing cavity, the core component of stainless steel laser welding machine, adopts imported ceramic reflective condensing cavity, single / double pulse xenon lamp, light on power supply, LCD motion control system, X / Y-axis electric platform / rotating axis (optional), CCD monitoring system (optional), and special laser chiller.

Performance characteristics of stainless steel laser welding machine:

1. High processing efficiency: the laser realizes the rapid movement of laser points through the oscillation of galvanometer, which greatly reduces the space positioning time, and the production efficiency is 4-10 times higher than that of ordinary laser spot welding

2. Uniform spot and good welding effect: the laser beam is collimated into parallel light through the collimating lens, and then focused on the workpiece for welding

3. Simple and convenient operation: stainless steel laser welding machine provides special laser welding software based on Windows platform. Welding points or graphics can be directly input and edited in its special software, or edited by AutoCAD, CorelDRAW and other software, and then imported and processed through its special software.

4. High stability: double closed-loop precision control is adopted to ensure that the energy of each solder joint is uniform.

Industry applications:

Stainless steel laser welding machine is suitable for mold manufacturing and forming of gold, silver, silver, stainless steel, titanium steel, digital products, toys, automobiles, motorcycles, sensors and meters, precision machinery, hardware, auto parts, computer accessories, and welding of non-standard metal materials and devices. It is also suitable for aluminum, copper, titanium, and other metals and alloys, It can realize the welding between different materials, such as low carbon steel steel, titanium gold, copper brass, copper titanium, etc.

Pre sales service

1. Free proofing for customers and help customers overcome process difficulties.

2. Provide customers with technical consulting services free of charge to ensure that the equipment selected by customers can really meet their needs.

Related Keywords