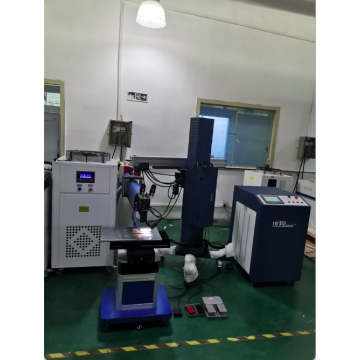

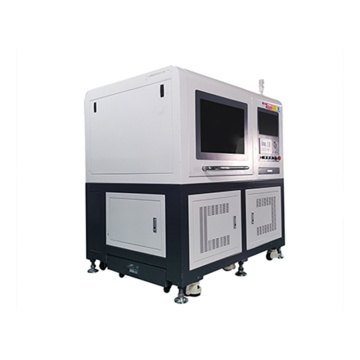

1000W laser welding machine

-

$20000.00≥15000 Set/Sets

- Min. Order:

- 15000 Set/Sets

- Min. Order:

- 15000 Set/Sets

- Transportation:

- Ocean, Land, Express

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Payment Type: | L/C,T/T,D/P,D/A,Paypal |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP |

| Transportation: | Ocean,Land,Express |

Product Description

Product Description

1000W fiber laser handheld welding machine. It has a lot of new ideas based on the humanization and effectiveness of the work in the aspects of equipment shape, structure and man-machine interface suitable for operation.

Advantages of laser welding

It is characterized by non-contact welding, without stress and deformation caused by external force;

Because the heating time is only a few milliseconds, the thermal effect on the material is only limited in the range of laser focus spot, and the welding heat affected zone is very small;

Multi point welding technology is usually used to reduce the influence of welding deformation on the performance of optoelectronic devices;

The welding process is measured in milliseconds, which has a very high production efficiency, making it possible for large-scale production.

Advantages of handheld laser welding machine

The equipment adopts integrated design with compact and beautiful structure, good beam mode, stable energy and stable performance;

Domestic 1000W fiber laser, excellent beam quality, maintenance free, photoelectric conversion efficiency more than 25%, pump life more than 100000 hours;

It is characterized by reliable use, fast welding speed, wide welding range, long service life of consumables and consumable parts, etc;

Fully consider various parameters of the equipment in batch production, and achieve the key parameters adjustable and data display closed-loop from the details.

Model characteristics

It is widely used in cabinet, kitchen, elevator, stainless steel home and other hardware industries, and can perfectly replace the traditional hydrogen arc welding;

The internal design is ingenious, the welding seam is beautiful, and the speed is fast;

Light shape, advanced structure and reliable performance;

With multiple safety alarms, it can automatically lock the light after moving the workpiece, with high safety;

Various angle nozzles can be configured to meet the welding requirements of different products.

technical parameter

Advantages of laser welding

It is characterized by non-contact welding, without stress and deformation caused by external force;

Because the heating time is only a few milliseconds, the thermal effect on the material is only limited in the range of laser focus spot, and the welding heat affected zone is very small;

Multi point welding technology is usually used to reduce the influence of welding deformation on the performance of optoelectronic devices;

The welding process is measured in milliseconds, which has a very high production efficiency, making it possible for large-scale production.

Advantages of handheld laser welding machine

The equipment adopts integrated design with compact and beautiful structure, good beam mode, stable energy and stable performance;

Domestic 1000W fiber laser, excellent beam quality, maintenance free, photoelectric conversion efficiency more than 25%, pump life more than 100000 hours;

It is characterized by reliable use, fast welding speed, wide welding range, long service life of consumables and consumable parts, etc;

Fully consider various parameters of the equipment in batch production, and achieve the key parameters adjustable and data display closed-loop from the details.

Model characteristics

It is widely used in cabinet, kitchen, elevator, stainless steel home and other hardware industries, and can perfectly replace the traditional hydrogen arc welding;

The internal design is ingenious, the welding seam is beautiful, and the speed is fast;

Light shape, advanced structure and reliable performance;

With multiple safety alarms, it can automatically lock the light after moving the workpiece, with high safety;

Various angle nozzles can be configured to meet the welding requirements of different products.

technical parameter

| ModelNo. | WY180A/WY300A | WY180B/WY300B |

| LaserPower | 180W/300W | 180W/300W |

| PowerStability | optionalenergynegative-feedbackpower:±2% | |

| LaserWavelength | 1064nm | |

| PulseWidth | ≤20ms | |

| PulseFrequency | ≤100Hz | |

| WeldingSpotDiameter | 0.2-1.5mm | |

| MaxWeldingDepth | ≤1.2mm | |

| illerWiresDiameter | 0.4-1.0mm | |

| PowerConsumption | 6KW/12KW 6KW/12KW | |

| PowerSupply | AC220V/AC380V AC220V/AC380V | |

| BenchLoad | ≤100kg | |

| BenchStroke | 250*150mm | |

| ArmStroke | / | 200*200mm, armrotatesfor3o0^hiontally |

| OperationInterface | 7”LEDtouchcontrolinterface.Chinese/Englishavailable | |

| LiftingStroke | Electricaliting250mm | |

| RepeatingAccuracy | ±0.01mm | |

| PositioningAccuracy | ±0.02mm | |

| LocatingSystem | redlaser,CCDmonitorsystem,optional fixture | |

| CoolingMethod | water cooling | |

| HostDimensions | 1600*700*1350mm | 1350*800*1420mm |

| AmbientEnvironment |

5'C-30℃,5%-75%humidity |

|

Sample display:

Related Keywords

Related Keywords