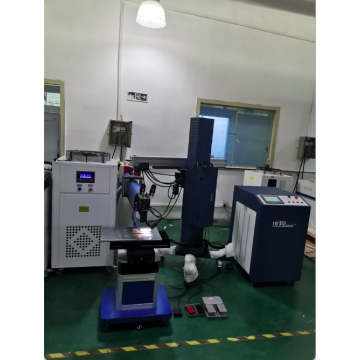

Stainless steel faucet laser welding machine

-

$20000.00≥10000 Set/Sets

- Min. Order:

- 10000 Set/Sets

- Min. Order:

- 10000 Set/Sets

- Transportation:

- Ocean

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | L/C,T/T,D/P,D/A,Paypal |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,DEQ,DDP,DDU,Express Delivery,DAF,DES |

| Transportation: | Ocean |

Machining principle of laser welding for Faucet:

The structure of the faucet is special, especially the welding at the corner, which is the difficulty of the welding process. The stainless steel faucet laser welding machine uses high-energy pulsed laser to weld the object. After the xenon lamp pulse discharge by laser power supply, the light wave with a certain frequency and pulse width is radiated to Nd3 +: YAG crystal through the concentrating cavity. The crystal emits 1064nm pulse laser after resonance, and then is welded after beam expansion, reflection and aggregation. The equipment is equipped with CNC worktable controlled by PLC or industrial PC. during welding, the laser frequency, pulse width, worktable speed and moving direction are welded with high precision.

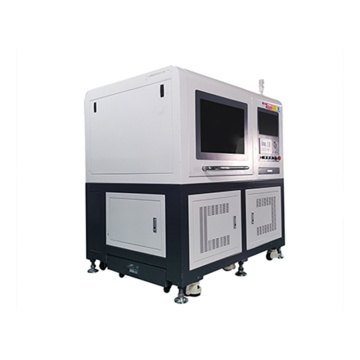

Continuous fiber laser welding machine is composed of "welding host" and "welding workbench". This series of equipment has a number of workbenches to choose from, which can fully meet the needs of users in different industries.Advantages of faucet laser welding machine:

1. It can realize automatic welding;

2. The equipment does not need technicians to operate, which saves labor cost for the enterprise;

3. High efficiency of laser welding, smooth and beautiful welding workpiece, no need to polish;

4. Laser welding belongs to non-contact welding, which can weld very narrow gap;

5. The equipment is easy to operate, without the operation of technical personnel, new employees can work quickly, saving training time for enterprises;

6. There is no radiation in the operation of the equipment and no harm to the operators. And it is safer than other welding equipment, greatly reducing the incidence of industrial injury for enterprises;

|

model |

UK-HJLX-SC500W |

UK-HJLX-SC1000W |

UK-HJLX-SC1500W |

|

|

500w |

1000w |

1500w |

|

Laser wavelength

|

1070±5 nm |

1070±5 nm |

1070±5 nm |

|

Operation mode

|

Continuous / modulation |

Continuous / modulation |

Continuous / modulation |

|

Output welding joint type |

Hand held swinging head |

Hand held swinging head

|

Hand held swinging head |

|

Output power stability |

<3% |

<3% |

<3% |

|

Power regulation range |

10~100% |

10~100% |

10~100% |

|

Weld penetration

|

0.5~2.0mm |

0.5~2.0mm |

0.5~2.0mm |

|

Spot width

|

0.2-3mm |

0.2-3mm |

0.2-3mm |

|

Cooling mode

|

Built in water cooling |

Built in water cooling |

Built in water cooling |

|

Fiber line length

|

Standard 10 meters, Max15 meters |

Standard 10 meters, Max15 meters |

Standard 10 meters, Max15 meters |

|

Blowing protection |

Argon, nitrogen |

Argon, nitrogen |

Argon, nitrogen

|

|

Electricity demand

|

AC220v/50Hz |

AC220v/380v/50Hz |

AC380v/50Hz |

|

Equipment power

|

3.5 Kw |

4.5 Kw |

5.5 Kw |

|

area covered

|

1*1.6m |

1*1.6m |

1*1.6m |

|

Overall weight |

180 Kg |

200 Kg |

200 Kg |

|

working temperature |

0~40°C |

0~40°C |

0~40°C |

|

Working humidity |

10~75% |

10~75% |

10~75% |

|

Environmental requirements

|

No vibration, no interference source, keep ventilation |

No vibration, no interference source, keep ventilation |

No vibration, no interference source, keep ventilation |

|

Consumables

|

Purified water, argon

|

Purified water, argon

|

Purified water, argon

|

Related Keywords