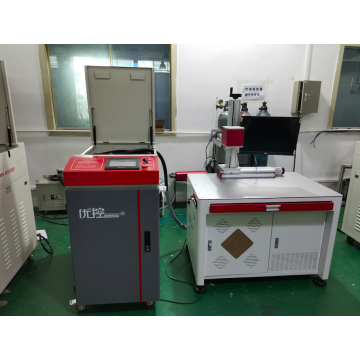

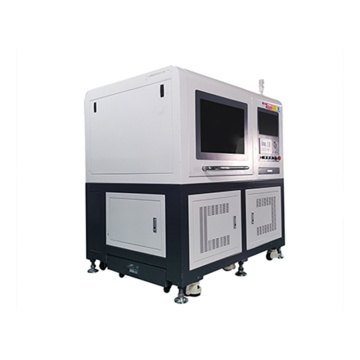

micro laser welding machine

-

$20000.00≥10000 Set/Sets

- Min. Order:

- 10000 Set/Sets

- Min. Order:

- 10000 Set/Sets

- Transportation:

- Ocean, Land, Express

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Payment Type: | L/C,T/T,D/P,D/A,Paypal |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP |

| Transportation: | Ocean,Land,Express |

Product Description

Product Description

Product introduction:

Optical fiber hand-held laser welding machine uses hand-held welding gun to replace the previous fixed light path, hand welding, flexible and convenient, welding distance is longer, overcome the limitations of the workbench space, when the size of the workpiece is not uniform, it can not be used in the case of automatic welding. Mainly for large workpieces, fixed position such as inner right angle, outer right angle, plane welding, small heat affected area, small deformation, large welding depth and firm welding. It is a flexible new welding process for long distance welding of large workpieces.

Product application:

It is used for welding shelves, kitchenware, daily kitchenware, stainless steel doors and windows, oven, power distribution box, aluminum alloy doors and windows, stainless steel furniture, stainless steel exhibition stand, etc.

Product features:

Small and beautiful, easy to move push-pull handle, universal caster, can move around, easy to weld objects that are not easy to move;

Flexible, portable and free welding hand-held laser head, light and flexible, can realize the welding of workpiece parts, and is not easy to fatigue;

Compared with traditional laser welding, hand-held laser welding has obvious advantages and low maintenance cost, which can meet the welding needs of different products;

Core accessories: double temperature and double control water cooling, with stable performance and long service life, can protect the normal operation of the machine and prolong the service life.

Optical fiber hand-held laser welding machine uses hand-held welding gun to replace the previous fixed light path, hand welding, flexible and convenient, welding distance is longer, overcome the limitations of the workbench space, when the size of the workpiece is not uniform, it can not be used in the case of automatic welding. Mainly for large workpieces, fixed position such as inner right angle, outer right angle, plane welding, small heat affected area, small deformation, large welding depth and firm welding. It is a flexible new welding process for long distance welding of large workpieces.

Product application:

It is used for welding shelves, kitchenware, daily kitchenware, stainless steel doors and windows, oven, power distribution box, aluminum alloy doors and windows, stainless steel furniture, stainless steel exhibition stand, etc.

Product features:

Small and beautiful, easy to move push-pull handle, universal caster, can move around, easy to weld objects that are not easy to move;

Flexible, portable and free welding hand-held laser head, light and flexible, can realize the welding of workpiece parts, and is not easy to fatigue;

Compared with traditional laser welding, hand-held laser welding has obvious advantages and low maintenance cost, which can meet the welding needs of different products;

Core accessories: double temperature and double control water cooling, with stable performance and long service life, can protect the normal operation of the machine and prolong the service life.

Sample display:

Related Keywords

Related Keywords