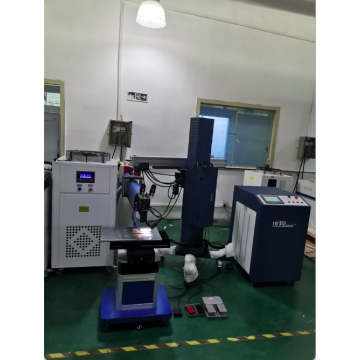

Automatic laser die welding machine

-

$25000.00≥10000 Set/Sets

- Min. Order:

- 10000 Set/Sets

- Min. Order:

- 10000 Set/Sets

- Transportation:

- Ocean, Land, Express

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | L/C,T/T,D/P,D/A,Paypal |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP |

| Transportation: | Ocean,Land,Express |

Product introduction:

After a series of processing, the light emitted by the laser generator is focused by the lens, and the energy is concentrated in a very small range. If the processed material absorbs the laser better, the material in the irradiated area will be heated to absorb the energy of the light. According to different materials and properties (such as melting point, boiling point, temperature of biochemical change), the workpiece will undergo a series of physical or chemical changes, such as melting, gasification, oxide formation, discoloration and so on.

Product features:

High speed electronic filter microscope with built-in electro-optic auxiliary protection device can effectively protect the operator's eyes.

10 times magnification of the microscope, cross cursor indication can achieve accurate alignment, and the shielding gas output synchronously with the laser can ensure the beautiful solder joint

The laser repair welding has the advantages of small heat affected zone, no deformation of precision die, large welding depth, firm welding and sufficient melting

It can be used for local heat treatment of parts, processing of complex shape parts and micro parts, and processing in vacuum

There is no pre-treatment, and the workpiece will not be annealed, deformed edge collapse, porosity and trachoma after welding

Product application:

It is suitable for laser repair welding of all kinds of high precision injection mold, precision plastic mold parts and beryllium copper plastic mold parts; It can be used to repair the wear of the mold shell in the process of using; It plays a key role in the mold modification for the mechanical machining error, EDM error, mold glue reducing design change and so on, which can make up for the huge loss caused by machining error.

Technical Parameters:

|

Parameter name |

Parameter value |

|

Maximum laser power |

500W |

|

The laser wavelength, |

1064nm |

|

Laser type |

ND :YAG |

|

Adjustable spot range |

0.1mm-3.0mm |

|

Cooling Type |

Water cooling |

|

Welding Depth |

≤3.0mm3.0 mm or less |

|

Pulse frequency |

0-100HZ |

|

Welding Wire Type |

0.1mm-0.8mm |

|

Observation system |

The microscope |

|

Position indicating |

LD 650nm |

|

Shielding gas |

Argon gas |

|

Output focal length |

80mm-200mm (80mm is standard, others are optional) |

|

Host power consumption |

≤11KW 11 kw or less |

|

Electricity Demand |

380V/50HZ/60A |

|

Workbench |

X,Y,Z/ load is less than 250KG |

|

Installation Area |

2.5mx2.5m |

|

|

|

Related Keywords