Laser spot welding machine for jewelry

-

$20000.00≥15000 Set/Sets

- Min. Order:

- 15000 Set/Sets

- Min. Order:

- 15000 Set/Sets

- Transportation:

- Ocean, Land, Express

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Payment Type: | L/C,T/T,D/P,D/A,Paypal |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP |

| Transportation: | Ocean,Land,Express |

Product Description

Product Description

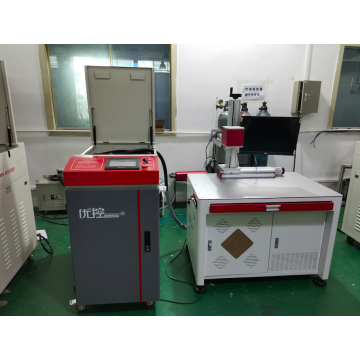

Integrated laser welding machine for jewelry

Jewelry laser welding machine, using laser deposition welding, uses laser high thermal energy and centralized fixed-point welding technology. Surface heat is transferred to internal diffusion. By controlling parameters such as laser pulse width, energy, peak power and repetition frequency, the workpiece is melted to form a specific molten pool. Because of its unique advantages, it is widely used in gold and silver jewelry processing and welding of small and small parts.

Features of laser welding machine for jewelry

1. Energy, pulse width, frequency and spot size can be adjusted in a large range to achieve a variety of welding effects, with small heat affected area and no product deformation;

· 2. The ceramic concentrator is corrosion-resistant, high temperature resistant and high photoelectric conversion efficiency;

3. Advanced automatic shading system is adopted to eliminate eye irritation during working hours;

The welding depth is large and the welding is firm;

Full melting, no sand hole and no repair trace;

6. It has the ability to work continuously for 24 hours, and the working performance of the whole machine is stable.

Application fields of laser welding machine for jewelry

Jewelry laser welding machine, using laser deposition welding, uses laser high thermal energy and centralized fixed-point welding technology. Surface heat is transferred to internal diffusion. By controlling parameters such as laser pulse width, energy, peak power and repetition frequency, the workpiece is melted to form a specific molten pool. Because of its unique advantages, it is widely used in gold and silver jewelry processing and welding of small and small parts.

Features of laser welding machine for jewelry

1. Energy, pulse width, frequency and spot size can be adjusted in a large range to achieve a variety of welding effects, with small heat affected area and no product deformation;

· 2. The ceramic concentrator is corrosion-resistant, high temperature resistant and high photoelectric conversion efficiency;

3. Advanced automatic shading system is adopted to eliminate eye irritation during working hours;

The welding depth is large and the welding is firm;

Full melting, no sand hole and no repair trace;

6. It has the ability to work continuously for 24 hours, and the working performance of the whole machine is stable.

Application fields of laser welding machine for jewelry

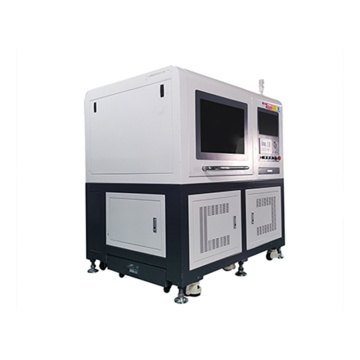

Widely used in precision machining of small parts, jewelry, denture, communication products, hardware, clocks, stainless steel, etc

Sample display:

Related Keywords

Related Keywords