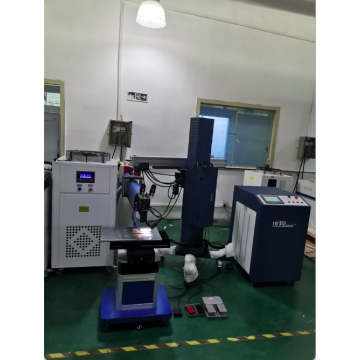

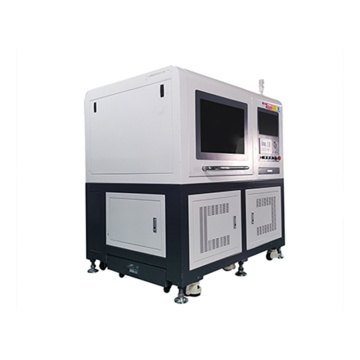

Knife mold laser welding machine

-

$25000.00≥10000 Set/Sets

- Min. Order:

- 10000 Set/Sets

- Min. Order:

- 10000 Set/Sets

- Transportation:

- Ocean, Land, Express

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | L/C,T/T,D/P,D/A,Paypal |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP |

| Transportation: | Ocean,Land,Express |

Performance characteristics:

1. X, y manual working platform, electric z-axis lifting, easy to operate;

2. The heat affected area is small, the welding depth is large, the melting is sufficient, and no repair trace is left;

3. The laser can move up and down, back and forth, and the worktable can be electrically operated up and down. It is mainly used for large and medium mold repair;

4. Liquid crystal light barrier can automatically adjust the amount of light barrier according to the pulse width to protect the operator's eyes from strong light;

5. Adjustable protective gas switch can blow gas in advance and turn off gas in delay to ensure that the welding spot is not oxidized;

Application materials:

S136, SKD-11, nak808407718738, H13, P20, w302344 and other die steel, carbon steel, ordinary alloy steel, stainless steel, beryllium copper, red copper and very hard alloy materials

Application fields:

Plastic mold, casting mold, forging mold, stamping mold, die casting mold, mobile phone, digital products, automobile and motorcycle mold manufacturing and molding industry.

Technical Parameters:

Parameter name

Parameter value

Maximum laser power

500W

The laser wavelength,

1064nm

Laser type

ND :YAG

Adjustable spot range

0.1mm-3.0mm

Cooling Type

Water cooling

Welding Depth

≤3.0mm3.0 mm or less

Pulse frequency

0-100HZ

Welding Wire Type

0.1mm-0.8mm

Observation system

The microscope

Position indicating

LD 650nm

Shielding gas

Argon gas

Output focal length

80mm-200mm (80mm is standard, others are optional)

Host power consumption

≤11KW 11 kw or less

Electricity Demand

380V/50HZ/60A

Workbench

X,Y,Z/ load is less than 250KG

Installation Area

2.5mx2.5m

Related Keywords