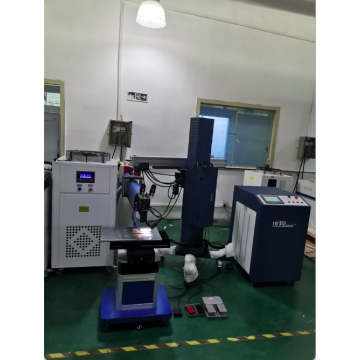

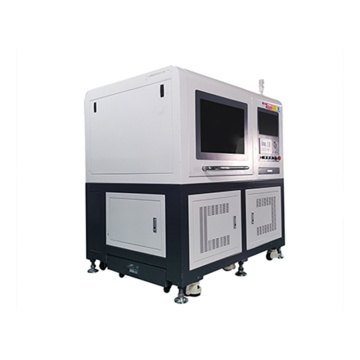

Mold laser welding machine

-

$25000.00≥10000 Set/Sets

- Min. Order:

- 10000 Set/Sets

- Min. Order:

- 10000 Set/Sets

- Transportation:

- Ocean, Land, Express

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | L/C,T/T,D/P,D/A,Paypal |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP |

| Transportation: | Ocean,Land,Express |

Mold Laser Welding Machine

Laser Welders Product Description

Laser processing is to irradiate the surface of the workpiece, use the Laser high energy to cut off, melt the material and change the surface performance of the object. As the laser processing is non-contact processing, the tool will not directly grind with the surface of the workpiece to produce resistance, so the laser processing speed is very fast, the processing object is affected by the heat range is small and will not produce noise. Since the energy of laser beam and the moving speed of laser beam can be adjusted, the laser processing can be applied to different levels and ranges.

Features:

Non-contact processing, no tool wear, no need to change tools halfway, and the energy of high-energy laser beam and its moving speed are adjustable, so it can achieve a variety of processing purposes;

②

The Laser beam has high energy density, fast processing speed, small workpiece deformation , small heat affected area, and small subsequent processing;

③

It can process many kinds of metals and non-metals, especially the materials with high hardness, high brittleness and high melting point, and can process a wide range of materials

④

The laser beam is easy to guide and focus, and can be changed in all directions, and it is easy to process complex workpieces with the CNC system;

⑤

It is easy to combine with traditional production technology to form a production line, which is an extremely flexible processing technology.

⑥

Laser processing, high production efficiency, reliable quality, good economic benefits

Application

Widely used in 2344, S136, 718,738, skd-11, NAK80 and other mold steel, common alloy steel, stainless steel, carbon steel, copper, beryllium copper, plastic mold, stamping mold, die casting mold, etc.

Technical Parameters:

Parameter name

Parameter value

Maximum laser power

500W

The laser wavelength,

1064nm

Laser type

ND :YAG

Adjustable spot range

0.1mm-3.0mm

Cooling Type

Water cooling

Welding Depth

≤3.0mm3.0 mm or less

Pulse frequency

0-100HZ

Welding Wire Type

0.1mm-0.8mm

Observation system

The microscope

Position indicating

LD 650nm

Shielding gas

Argon gas

Output focal length

80mm-200mm (80mm is standard, others are optional)

Host power consumption

≤11KW 11 kw or less

Electricity Demand

380V/50HZ/60A

Workbench

X,Y,Z/ load is less than 250KG

Installation Area

2.5mx2.5m

Related Keywords