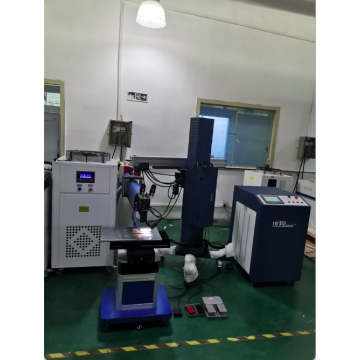

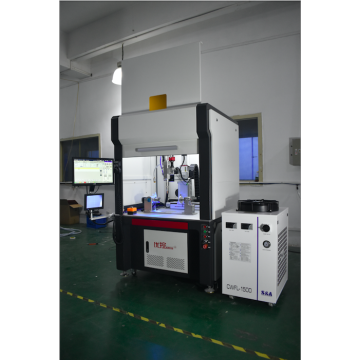

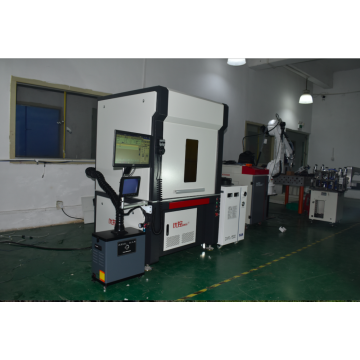

Optical fiber transmission laser welding machine

-

$8000.00≥2400 Set/Sets

- Min. Order:

- 2400 Set/Sets

- Min. Order:

- 2400 Set/Sets

- Transportation:

- Ocean, Land, Express

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | L/C,T/T,D/P,D/A,Paypal |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,DEQ,DDP |

| Transportation: | Ocean,Land,Express |

Optical fiber transmission laser welding machine

Product introduction

Youkong400 optical fiber transmission laser welding machine has the advantages of good beam quality and thin spot. Optical fiber transmission laser welding machine is a kind of laser welding equipment that laser is transmitted through optical fiber, collimated into parallel light through collimating lens, and then focused on the workpiece for welding. It can carry out long-distance and flexible welding operation, and can process multiple stations at the same time through light splitting.

Youkong400 optical fiber transmission laser welding machine is suitable for welding microelectronic components, precision parts, digital components, optical fiber connectors, medical devices, etc. Weldable materials: carbon steel, ordinary alloy steel, stainless steel, laser welding between different steels, stainless steel - low carbon steel, 416 stainless steel - 310 stainless steel, 347 stainless steel - hastally nickel alloy, nickel electrode - cold forged steel, bimetallic strip with different nickel content, titanium, nickel, tin, copper, aluminum, chromium, niobium, gold, silver and other metals and their alloys, and steel Welding between the same materials of Kovar alloy and other alloys. Copper nickel, nickel titanium, copper titanium, titanium molybdenum, brass copper, low carbon steel copper and other dissimilar metals

The unique trusteeship device keeps contact with the surface of the pipe when the pipe is fed and rotated. The support force is set according to the pipe specification to ensure effective support, prevent the pipe from sagging, reduce the axis swing when the pipe rotates, and improve the processing accuracy.

Automatic whole bundle feeding function (optional), reduce the number of operators and improve the processing efficiency at the same time.

|

model |

UK-HJLX-SC500W |

UK-HJLX-SC1000W |

UK-HJLX-SC1500W |

|

|

500w |

1000w |

1500w |

|

Laser wavelength

|

1070±5 nm |

1070±5 nm |

1070±5 nm |

|

Operation mode

|

Continuous / modulation |

Continuous / modulation |

Continuous / modulation |

|

Output welding joint type |

Hand held swinging head |

Hand held swinging head

|

Hand held swinging head |

|

Output power stability |

<3% |

<3% |

<3% |

|

Power regulation range |

10~100% |

10~100% |

10~100% |

|

Weld penetration

|

0.5~2.0mm |

0.5~2.0mm |

0.5~2.0mm |

|

Spot width

|

0.2-3mm |

0.2-3mm |

0.2-3mm |

|

Cooling mode

|

Built in water cooling |

Built in water cooling |

Built in water cooling |

|

Fiber line length

|

Standard 10 meters, Max15 meters |

Standard 10 meters, Max15 meters |

Standard 10 meters, Max15 meters |

|

Blowing protection |

Argon, nitrogen |

Argon, nitrogen |

Argon, nitrogen

|

|

Electricity demand

|

AC220v/50Hz |

AC220v/380v/50Hz |

AC380v/50Hz |

|

Equipment power

|

3.5 Kw |

4.5 Kw |

5.5 Kw |

|

area covered

|

1*1.6m |

1*1.6m |

1*1.6m |

|

Overall weight |

180 Kg |

200 Kg |

200 Kg |

|

working temperature |

0~40°C |

0~40°C |

0~40°C |

|

Working humidity |

10~75% |

10~75% |

10~75% |

|

Environmental requirements

|

No vibration, no interference source, keep ventilation |

No vibration, no interference source, keep ventilation |

No vibration, no interference source, keep ventilation |

|

Consumables

|

Purified water, argon

|

Purified water, argon

|

Purified water, argon

|

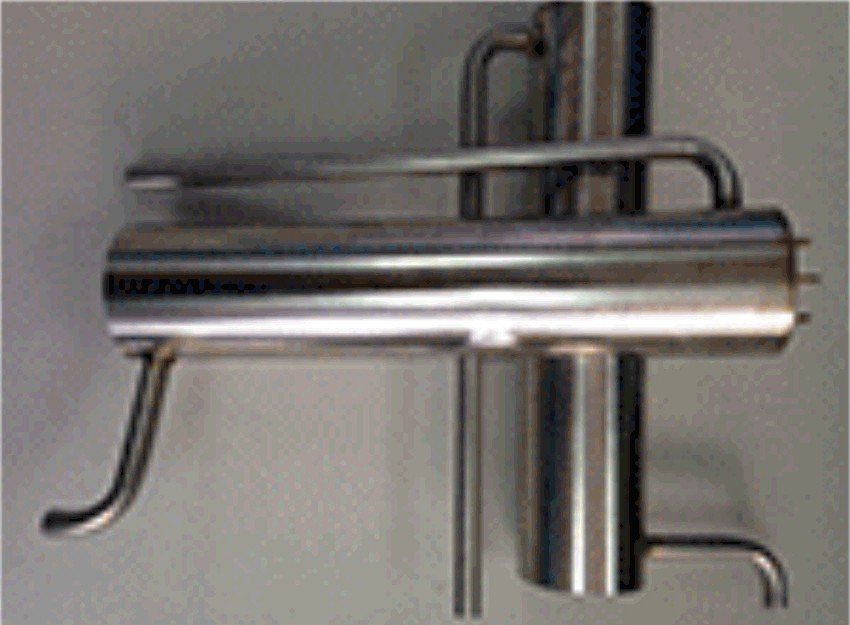

Working drawing

Related Keywords