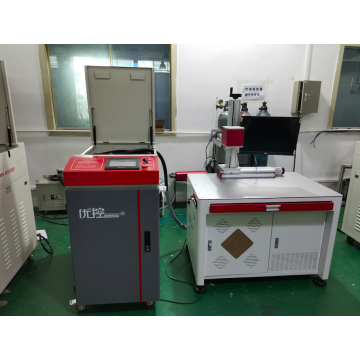

200W Automatic Laser Welding machine

-

$25000.00≥4800 Set/Sets

- Min. Order:

- 4800 Set/Sets

- Min. Order:

- 4800 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | L/C,T/T,D/P,D/A,Paypal |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP |

| Transportation: | Ocean,Land,Air,Express |

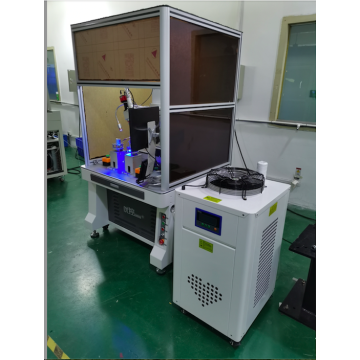

Excellent control laser automatic laser welding machine is widely used for laser welding of electric kettle with material thickness less than 1.0mm, laser welding of heating plate, laser welding of kettle nozzle, stainless steel water cup and other 3D curved surfaces. Equipped with professional industrial computer and multi axis NC software, X / Y / Z / u four axis linkage can realize laser welding of most hardware products.

Scope of application

Excellent control automatic laser welding machine is a high stability and high-power welding machine, which can meet the needs of long-time production. High power laser power supply and high-power heat dissipation system meet 24-hour mass production. The fuselage adopts high-strength structure to ensure accuracy and stable performance. The control system is a professional 4-axis control system specially tailored for laser welding, with high stability, easy to learn, understand and use. With strong expansibility, it can be combined with assembly line, photoelectric sensor, pneumatic fixture and other combinations for full-automatic unattended processing.

Scope of application: bathroom industry: 3D and spatial curve welding of water pipe joints, reducing joints, tees, valves and sprinkler heads.

Battery industry: laser welding of lithium battery, battery pack and electrode.

Glasses industry: precision welding of glasses buckle and outer frame made of stainless steel and titanium alloy.

Hardware industry: welding of impeller, kettle, handle, complex stamping parts and castings.

Professional laser power control system

1. The function of the whole machine is to control and correct the laser output based on the adjustment of the output current, so as to use the laser for welding safely and effectively;

2. The main controller adopts a new armv7 series processor with high processing speed to meet the real-time control of the equipment. It can quickly and accurately control and protect the laser machine. Provide customers with a fast and safe use experience as much as possible.

Related Keywords