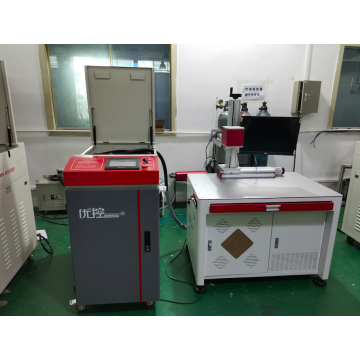

Brand of handheld laser welding machine

-

$8000.00≥4000 Set/Sets

- Min. Order:

- 4000 Set/Sets

- Min. Order:

- 4000 Set/Sets

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | L/C,T/T,D/P,D/A,Paypal |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP |

| Transportation: | Ocean,Land,Air |

Hand-held Integrated Laser Welding Machine, with hand-held welding gun instead of the previous fixed light path, hand welding, flexible and convenient, welding distance is longer, overcome the limitations of the workbench space, workpiece size is not uniform, can not be used in the case of automatic welding. Mainly for large workpieces, fixed position such as inner right angle, outer right angle, plane welding, small heat affected area, small deformation, large welding depth and firm welding. It is a flexible new welding process for long distance welding of large workpieces.

Hand-held Integrated Laser Welding Machine Product principle:

1. The hand-held welding gun is more flexible and convenient to replace the previous fixed light path to realize long-distance laser welding and overcome the limitation of the travel space of the worktable;

2. The hand-held welding joint is light and flexible, easy to operate, and can meet the requirements of welding at various angles and positions;

3. The portable welding head can be equipped with 5 m / 10 m imported optical fiber, which is flexible and convenient to realize outdoor welding;

4. Infrared positioning is used to calibrate the position of welding joint and verify the position during welding. The welding position is more accurate and the weld is more beautiful;

Hand-held Integrated Laser Welding Machine Advantages and disadvantages:

1. The laser beam quality is good, the welding speed is fast, the welding seam is firm and beautiful, and it brings efficient and perfect welding solutions for users.

2. Hand held water-cooled welding gun, ergonomic design, flexible and convenient, longer welding distance, can achieve any part of the workpiece angle welding.

3. The welding area has small heat effect, is not easy to deform, blackens, and has traces on the back. The welding depth is large, and the melting is sufficient, firm and reliable.

4. Electro optic conversion efficiency is high, energy consumption is low, and the operation is simple and easy to learn, without professional welding master, ordinary workers can work after a short training. Long term use can greatly save processing costs.

5. High safety, the welding nozzle can only touch the metal when the touch switch is effective, and the touch switch has temperature sensing.

Index parameters:

Laser type: Fiber laser

Laser power: 1000-1500w

Laser wavelength: 1064nm

Cooling mode: water-cooling

Water temperature: 25℃

Welding speed: 10-40mm/s

Overall dimension (L) × wide × (high) 1000mm × 800mm × 1100mm

Control system: customized

Welding thickness: No more than 3mm stainless steel

Product splicing gap: Not more than 1 mm

Related Keywords