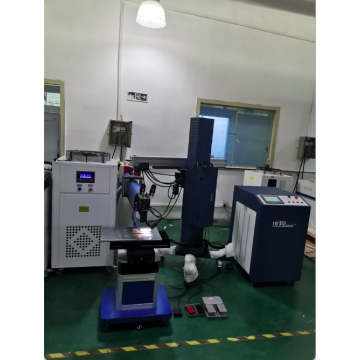

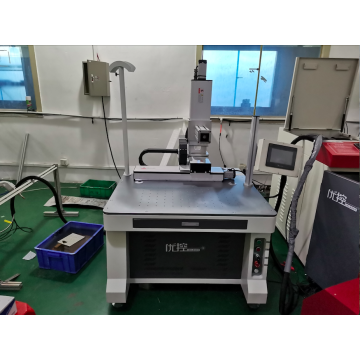

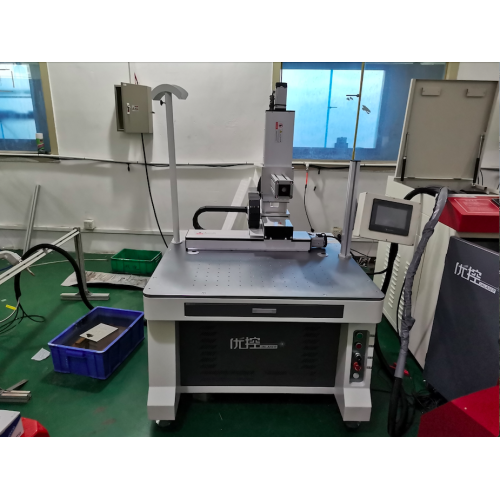

Handheld optical fiber transmission laser welding machine

-

$10000.00≥4000 Set/Sets

- Min. Order:

- 4000 Set/Sets

- Min. Order:

- 4000 Set/Sets

- Transportation:

- Ocean, Land, Express

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | L/C,T/T,D/P,D/A,Paypal |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP |

| Transportation: | Ocean,Land,Express |

1. Product introduction

Handheld continuous optical fiber welding machine "is composed of laser generator, refrigeration system, control system and handheld welding joint.

2. Preparations

① There are two kinds of power supplies for handheld continuous optical fiber welding machine, namely three-phase 380V and single-phase 220V. Please provide stable power supply according to the specific model of the equipment. The voltage fluctuation range is less than 5%. Unstable voltage will cause damage to laser generator or other components and other serious consequences.

② . the handheld continuous optical fiber welding machine needs to use inert gas such as nitrogen or argon for auxiliary welding. The gas pressure is about 0.3KG. Please select a suitable pressure reducing valve. Too large or too small pressure will affect the welding effect. The equipment is equipped with a new air pressure alarm device. When there is no air pressure or the air pressure is less than the set value, the alarm lamp will give an alarm.

③ Hand held continuous optical fiber welding machine needs to use about 25L pure water or distilled water. Tap water, well water and mineral water are strictly prohibited!

3. Introduction to use

① . startup process: open the air valve → open the air switch on the right side of the equipment → release the emergency stop button on the panel → turn the key to the right to turn on the system power → press the power button of the water turbine → press the blue on / off button on the water turbine control panel → press the laser power button, and wait for 20 seconds before use.

② Welding process: clamp the welding protection collet on the worktable; Check whether the process parameters are required by the current welding workpiece; Click the "open valve" button on the control system interface to check whether the blowing flow meets the welding requirements; Click the "start" button on the control system interface to test whether the light protection circuit works normally (align the welding joint with the surface of the test plate, press the light out button, and it is normal if there is no light out; Contact the welding joint with the surface of the test plate, press the light out button, and the light out is normal); Welding can be started after the test is correct.

③ . shutdown process: place the welding head on the welding head holder, click the "stop" button on the control system interface, turn off the laser power button → turn off the water machine power button → turn the system power key to the left and pull it out → press the emergency stop button → close the air switch on the right side of the equipment → close the air valve.

4. Precautions

① Radiation proof glasses and safety protective clothing must be worn to ensure the safe production of staff. All safety accidents caused by illegal operation have nothing to do with the company.

② During use, the welding joint must not be aligned with any part of the body.

③ In case of any accident, immediately press the emergency stop button and contact our personnel to reflect the situation.

④ If you stop working at 0:00, please click "stop" to enter the standby mode, or if you stop working after work, please click "stop" to enter the standby mode and turn off the equipment.

⑤ The power supply of the equipment must be turned off when replacing the protective lens or inspecting the welding joint.

⑥ Set the water temperature of the refrigerator, and the temperature difference between the refrigerator and the room temperature shall not be greater than 10 degrees! It is recommended to set the water temperature to 26 ℃ - 30 ℃ in summer and 20 ℃ - 22 ℃ in winter. Excessive temperature difference in the cabinet will cause condensation of laser devices, resulting in damage to the laser. Antifreeze measures must be taken when the room temperature is lower than 4 ℃. Ethylene glycol and purified water can be mixed in the ratio of 1:3 and added into the water tank after mixing evenly.

Related Keywords