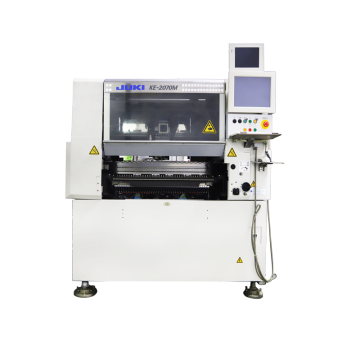

SMT high-speed placement machine price

- Payment Type:

- T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- Negotiable Days

- Transportation:

- Ocean, Land

- Port:

- Shenzhen, Guangzhou, Zhuhai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | shenzhen |

|---|---|

| Payment Type: | T/T |

| Incoterm: | FOB |

| Transportation: | Ocean,Land |

| Port: | Shenzhen,Guangzhou,Zhuhai |

SMT high-speed placement machine price

PCB Max Size: 330×250mm

Fixing Rail: Front Fixed

Components height : 5mm

Placement speed: 16,000CPH (IPC 9850)

Feeder inputs : Max. 80 on 8mm T/F6

Power supply : 200 to 415 VAC, 3-phase

Apparent power : 3kVA

Operating air pressure : 0.5±0.05Mpa

Air consumption : 345L/min (Opt.:Vacuum Pump 50L/min)

One multi-nozzle laser head (6 nozzles)

Machine dimensions : 1,400×1,393×1,455mm

Mass (approximately) : 1,530kg

Modified special-shaped plug-in machine JUKI-KE-2070CM:

The manual plug-in speed is too slow and the quality is unstable?

The fully automated plug-in machine has invested too much, and now the good news is coming. Shenzhen Kechuang Industrial Co., Ltd.'s subordinate brand sticking and inserting machine is developed to meet the current manual plug-in speed is too slow, difficult to use, and unstable quality.

Existing placement equipment can be used to achieve automatic plug-ins without affecting placement, saving you money and increasing productivity!

Features of modified special-shaped plug-in machine JUKI-KE-2070CM:

1. Using laser to identify component pins, it is easier to calibrate the pins than a camera to ensure that components are inserted correctly

Parameters of JUKI-KE-KE-2070CM

Alien Plug-in:

|

Feeder |

Bulk material, tray material, |

|

Number of feeders that can be loaded |

Tape feeder: 14 |

|

Material height |

Ke2050 height≤20mm Ke2060 height s25mm |

|

Material size |

KE2050: 0.6*0.3~ Line length 47MM

|

|

Number of plug-in headers |

Ke2050- .4个

|

|

Reclaiming method |

1. Draw |

|

Substrate size |

|

|

Plug-in accuracy |

+/-0.05MM

|

|

Plug-in speed

|

The fastest 0.7S/piece |

|

Equipment size |

1500*1500*1450MM

|

|

Power supply/power. |

Power supply: three-phase 380V |

|

Weight/air consumption |

Weight: 1500KG |

Company Overview

Our company integrates SMT equipment sales and maintenance.

The products cover all aspects of the SMT industry. The main business scope is placement machines, peripheral products, feeders, suction nozzles, and placement machine accessories services.

Engaged in the business of JUKI equipment and JUKI feeder for 14 years.

Strives for innovative development and dedication to provide you with assured quality products and services.

We provide customers with competitive, safe and reliable products, solutions and services in the fields of SMT patches and plug-ins.

Open cooperation with the industry's ecological partners, increase business barriers, continue to create value for customers, and insist on continuous innovation around customer needs.

Our team

We always put you first, continue to grow and innovate, and provide you with suitable solutions.

The brands we work with

We have in-depth discussions and cooperation with many brands, work down-to-earth, and win trust.

Actively expand products to SMT peripheral equipment.

Integrate the advantages of products to provide customers with a complete set of SMT equipment and production solutions, as well as a fully automated intelligent industry line.

Provide customers with a full range of solutions to achieve the goal of improving efficiency and reducing costs, so as to achieve a win-win situation for customers and the company.

Related Keywords