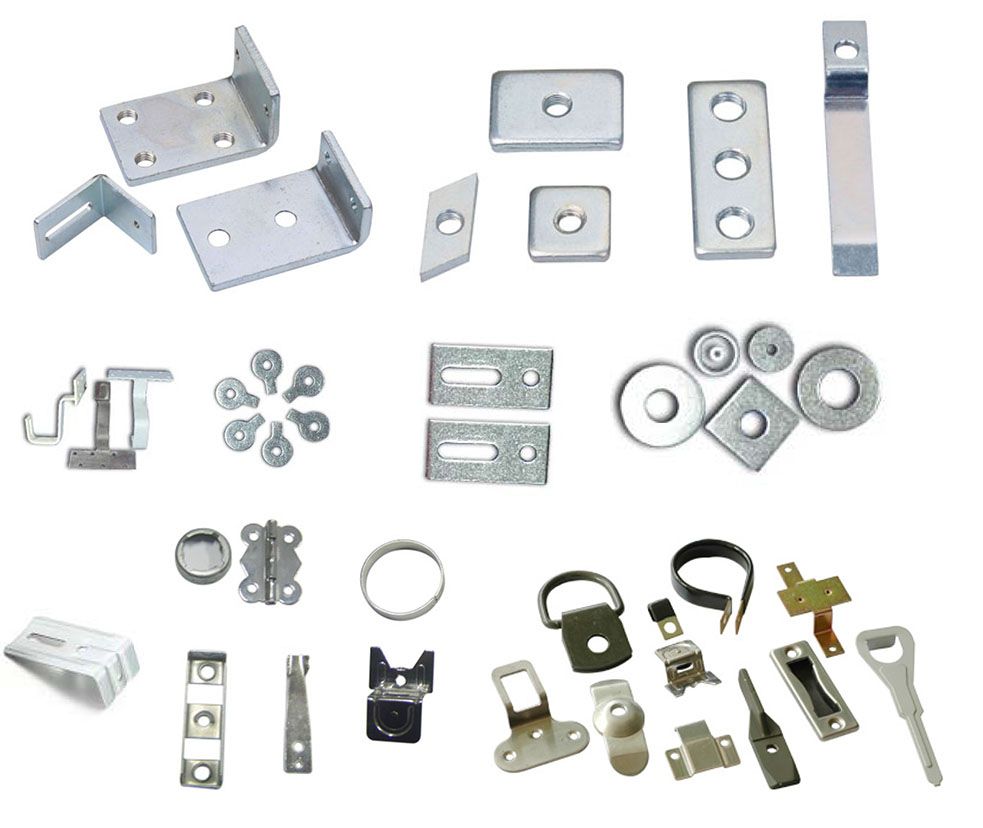

Sheet metal stamping parts/sheet metal fabrication

-

$6.00≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- ShenZhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 8000000 |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | IOS9001 |

| HS Code: | Non |

| Transportation: | Ocean,Land,Air |

| Port: | ShenZhen |

Stamping process is the basis of mold design, and a good mold structure design, but also to achieve the process of reliable guarantee, if the stamping process is changed, often cause mold rework, or even scrap. Several different methods can usually be used to punch the same part. The center of the process design is based on the principle of advanced technology, reasonable economy, efficient production, safe and reliable use, so that the production of parts in accordance with the premise of ensuring the technical requirements of parts, to achieve the best technical effect and economic benefits.

Determine the mold type and structure size, mold design

The general procedure for mold design is as follows:

1. Determine the mold type and structure form according to the determined process plan, shape characteristics of stamping parts, precision requirements, production

Batch, mold manufacturing and maintenance conditions, convenient operation and safety requirements, and the possibility of using and realizing mechanization automation

Determine the choice of composite die, continuous die or simple die. Special attention should be paid to making mold type, mold structure and mold strength,

Rigidity and service life requirements are coordinated.

2. The selection of workpiece positioning mode workpiece positioning in the mold mainly consider the positioning datum, feeding mode, safe and reliable operation

Factors. In order to make the positioning reliable, the surface with high precision and no deformation and movement during stamping should be selected as the positioning surface. Stamping parts can be used for positioning of the surface with different parts of the shape is different, flat parts are best used far from the two holes positioning, bottom or edge cutting flange positioning.

3 die parts for small and long punch, thin wall thickness of the concave die, etc., also need to carry out strength check. Such as

After determining the structural size of the die, the die frame can be selected according to the die perimeter. Mold closure height, profile size, pressure

The center should be adapted to the selection of equipment, and draw a sketch of the mold structure.

Why us?

We have many years of experience in sheet metal, CNC processing production, has an advanced sheet metal processing production line, equipped with laser cutting, CNC shear, CNC punching, CNC bending, automatic riveting, automatic welding, automatic spraying, tooling, polishing, screen printing, assembly, and another large workshop, has all kinds of advanced testing equipment, perfect testing process.

click request quotation

Related Keywords