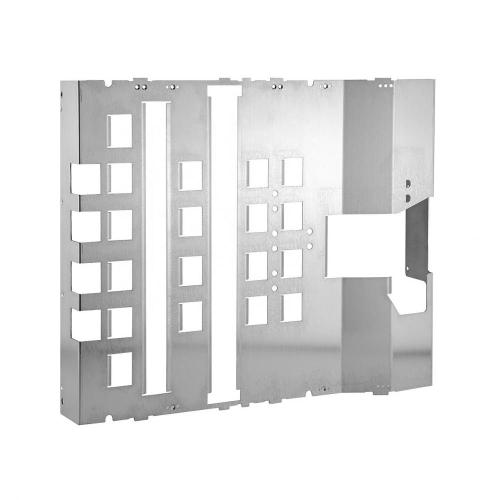

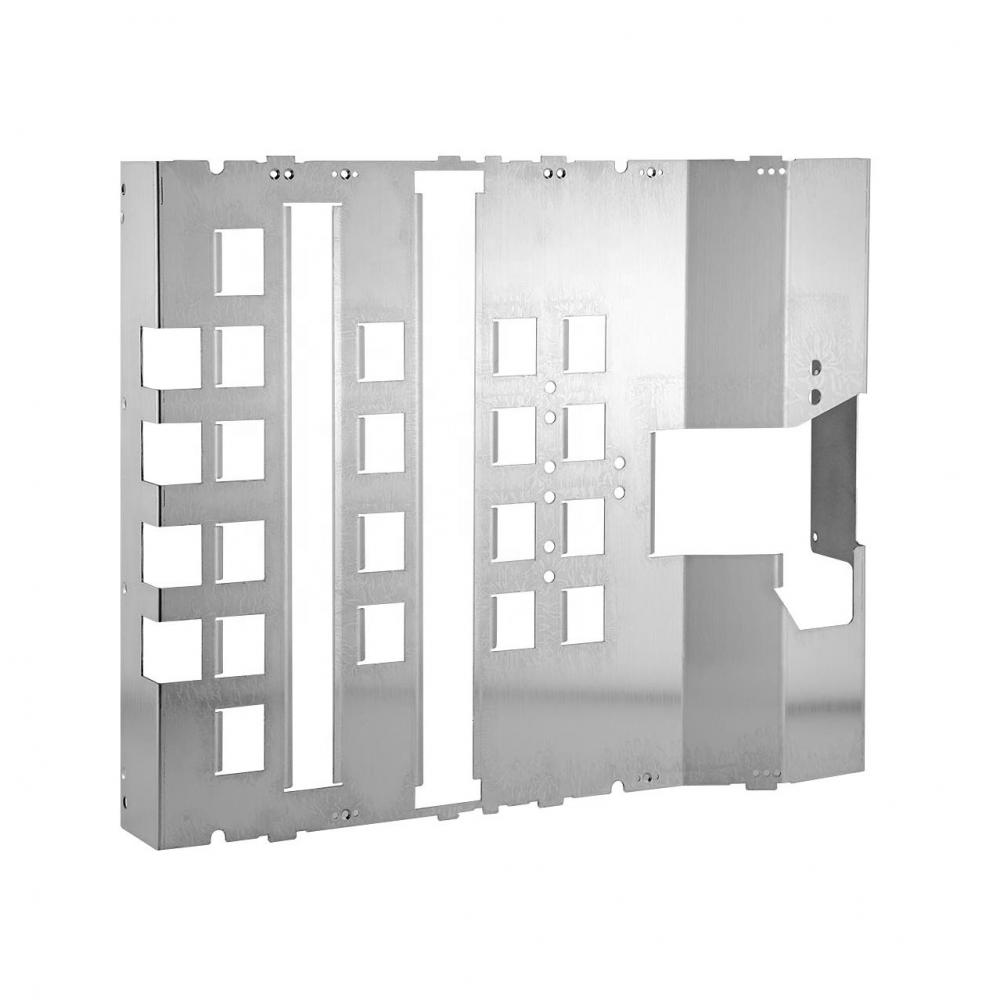

machinery sheet metal fabrication

-

$6.00≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- ShenZhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 8000000 |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | IOS9001 |

| HS Code: | Non |

| Transportation: | Ocean,Land,Air |

| Port: | ShenZhen |

Common sheet metal processing, mainly composed of six steps, the following with your specific introduction: sheet metal processing drawing design -- > laser processing or (CNC stamping) -- > bending -- > welding molding -- > electrostatic powder spraying or (liquid paint) -- > packaging shipment.

Sheet metal processing process:

1, drawing design: general customers to provide drawings or samples, by the company's engineering personnel to scale, design, expand, form a processing decomposition map and assembly map submitted to the production department for processing.

2, laser processing: with a large laser cutting machine, carbon steel, stainless steel, and other materials for cutting blanking, the use of laser cutting blanking, workpiece processing neat section, smooth and beautiful, accurate size, with the arc of the workpiece is more advantageous, is the general CNC stamping can not be replaced by the processing method.

3, CNC stamping: with imported turret CNC punch, CNC stamping mainly for product processing material thickness is thin, generally in the following 2.5mm material is more suitable, sheet metal processing workpiece hole more or need to open a special mold to process the workpiece, large batch with CNC stamping has a certain cost advantage.

4, bending: the workpiece under the good material, such as most of the need for bending molding, CNC bending machine, not only fast, more accurate workpiece processing.

5, welding forming: artifacts in general need to assemble after molding, there are many means of assembly, some directly with screws, pull the welding process such as forming, general mechanical shell use more welding sheet metal forming, the company usually adopt argon arc welding, touch welding, co2 welding, etc., after welding to grinding and polishing of artifacts, such artifacts are strong and beautiful.

6, electrostatic dusting: electrostatic dusting mainly for carbon steel workpiece, in the process of oil removal, cleaning, phosphating treatment, electrostatic dusting, high-temperature baking, and other processes, after the processing of the workpiece surface is beautiful, will not rust in a few years, low cost and other advantages.

Liquid paint: this craft and electrostatic spray powder have differences, general in the light of large workpieces, in the case of unable to carry the use of liquid paint has convenient, low cost and other advantages, liquid paint is generally divided into two steps, in the workpiece after processing primer again above paint.

7. Packaging and shipment: 100% inspection shall be carried out before packaging and inspection data shall be provided. The shipping requirements and packing method have been confirmed by the representative of the client on the spot and are hereby recorded for the client's reconfirmation

Often ask questions

What parts can you buy from Bergek?

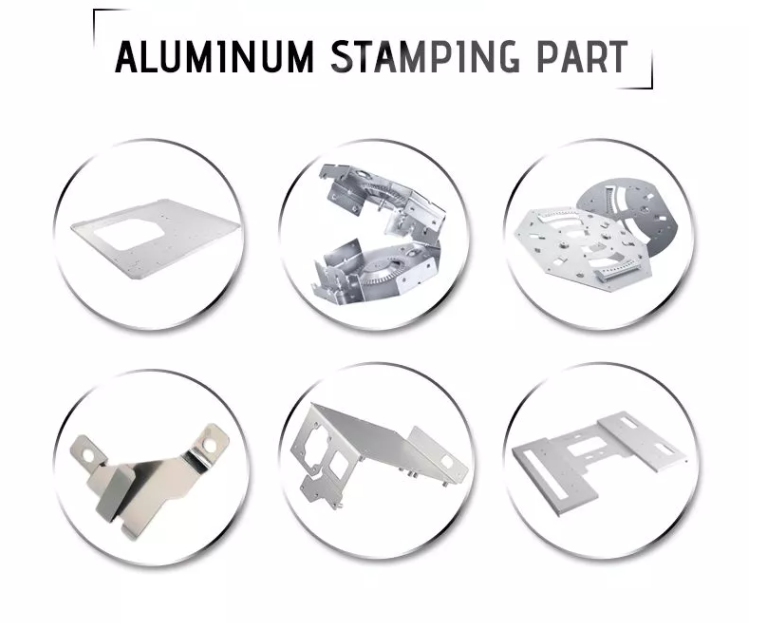

CNC machining milling parts/turning parts, stamping parts, sheet metal processing parts, bending parts

Why should you buy from Bergek instead of another vendor?

Focus on CNC processing and sheet metal processing, provide CNC turning, CNC milling, stamping bending, sheet metal manufacturing one-stop solution.

Can Bergek make the blueprints for me?

We do not provide design services. You are responsible for submitting 2D and 3D CAD drawings and then we can provide a manufacturing design review upon receipt of your order.

Bergek is a world-class manufacturing service provider in Shenzhen. We have advanced equipment to provide a full range of custom products to manufacturers around the world, focusing on CNC machining and sheet metal processing. Our goal is to make it easier to customize parts. So why not come and see our facilities for yourself? We stand ready to help you bring your next product to market, let us help you succeed! Please contact us with your inquiry.

click request quotation

Related Keywords