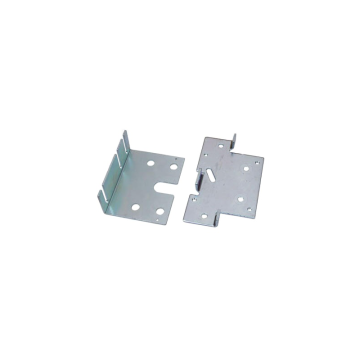

Custom sheet metal Stamping Parts service

-

$6.00≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- ShenZhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 8000000 |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | IOS9001 |

| HS Code: | Non |

| Transportation: | Ocean,Land,Air |

| Port: | ShenZhen |

Bending parts can often be seen in mechanical processing production, such as metal V shapes, U shapes,s, and so on. In the general common situation, there are two methods of metal bending, one dies bending, and the other is bending machine bending, the former is suitable for complex structures, small volumes, and large quantities of processing. The latter is suitable for machining structures with large sizes and small outputs. For bending parts of the processing technology, the following hook net gives you a specific introduction.

One, bending machine bending

The use of bending machine bending is mainly divided into ordinary bending and CNC bending two. CNC bending is mainly used for machining high precision requirements, bending irregular shapes of sheet metal bending, its basic principle is to use a bending machine bending knife, V-groove, bending and forming materials. Its advantages are convenient clamping, accurate positioning, and fast processing speed, and the disadvantage is that the pressure is small, can only process simple forming, low efficiency.

Two, CNC bending machine bending

Numerical control bending machine is the use of a numerical control system for the slider administration (punch into the concave die depth) and the position of the rear stopper for automatic control, in order to achieve different bending workpiece bending intersection and bending edge width bending forming. The process characteristics of a CNC bending machine are mainly high productivity, can improve the precision of bending parts, and simple operation, saving the middle stack area and reducing the labor intensity.

Product details

|

Aluminum Alloy

|

AL6061, AL6063, AL6082, AL7075, AL5052, etc.

|

|

Steel

|

Mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45#, etc.

|

|

Iron

|

A3, 45#, 1213, 12L14, 1215, etc.

|

|

Stainless Steel

|

SS201,SS301,SS303, SS304, SS316, SS416, etc.

|

|

Brass

|

HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90, etc.

|

|

Copper

|

C11000,C12000,C12000, C36000, etc.

|

|

Plastic Profile

|

ABS, PC, PE, POM, Nylon, PP, Peek, PTFE etc.

|

|

Steel Sheet Metal

|

Zinc plating, Oxide black, Nickel plating, Chrome plating, Painting, Powder Coated, etc.

|

|

Aluminum Sheet Metal

|

Clear Anodized, Color Anodized, Sandblast Anodized, Powder Coating, Painting, Chemical Film,Brushing,Polishing, etc.

|

|

Stainless Sheet Metal

|

Brush, Polishing, Nickel Plating, Chrome Plating

|

|

Copper & Brass Sheet Metal

|

Brush,

|

Picture case

Often ask questions

What parts can you buy from Bergek?

CNC machining milling parts/turning parts, stamping parts, sheet metal processing parts, bending parts

Why should you buy from Bergek instead of another vendor?

Focus on CNC processing and sheet metal processing, provide CNC turning, CNC milling, stamping bending, sheet metal manufacturing one-stop solution.

Can Bergek make the blueprints for me?

We do not provide design services. You are responsible for submitting 2D and 3D CAD drawings and then we can provide a manufacturing design review upon receipt of your order.

Bergek is a world-class manufacturing service provider in Shenzhen. We have advanced equipment to provide a full range of custom products to manufacturers around the world, focusing on CNC machining and sheet metal processing. Our goal is to make it easier to customize parts. So why not come and see our facilities for yourself? We stand ready to help you bring your next product to market, let us help you succeed! Please contact us with your inquiry.

click request quotation

Related Keywords