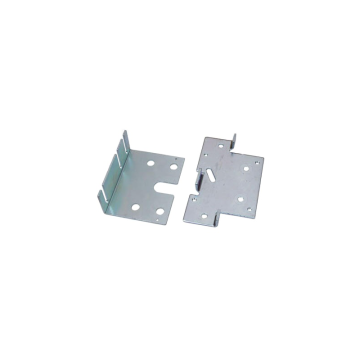

OEM Sheet Metal Bending Parts

-

$6.00≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- ShenZhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 8000000 |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | IOS9001 |

| HS Code: | Non |

| Transportation: | Ocean,Land,Air |

| Port: | ShenZhen |

With the development of society, the sheet metal processing industry is also developing rapidly, sheet metal industry involves various industries. What are the benefits of sheet metal processing? Or how to operate, the actual use of oil drums, iron pipes, and air pipes in daily life

The choice of sheet metal processing technology will directly affect the manufacturing cost, if the proofing parts are small batch, without indicating the number of subsequent processing, generally choose sheet metal processing, so that the price will be more reasonable; If it is a batch sheet metal processing, then use the stamping process.

Here are some of the sheet metal processing technology introduced, with cutting, deburring, bending, secondary processing, painting, such as processing technology, process burr be done by hand, the rest to complete by machine, with the right positioning fixture, the process can realize mechanization and automation, so as to greatly improve the part of the processing efficiency and product quality.

Product details

|

Advantage

|

One-Stop Solution for Mechanical Customers

Rich experience in Small Volume & Large variety Rich experience in Large Volume 29 Years field experience, and 80+ engineers |

|

Processing Method

|

CNC machining. Turning. Milling, Stamping, Sheet metal. Screw manufacturing, Assembly

|

|

Materials Available

|

Stainless steel Carbon steel, Brass, Bronze. Iron, Alumunum alloy, Nylon, SPCC, SECC, etc.

|

|

Materials Standard

|

GB. ASTM, EN, DIN, JIS, BS, ANSI. SAE

|

|

Processing Capacity

|

Outer diameter: 0.5mm-500mm Length: 1.0mm-2000mm

|

|

Tolerance

|

± 0.002mm

|

|

Surface Treatment

|

Anodizing, Sandblast, Electroplating. Powder coating.

Liquid Painting, PVD, Electrolytic polishing, ect. |

|

Equipment

|

Over 70 sets automatic lathes, over 30 sets CNC lathes,

over 10 sets CNC machining center, over 200 sets secondary processing machines. |

|

RFQ

|

Customer Inquiry → Engineering Communication → Cost Analysis →Sales Analysis →Quote to Customer

» 1-3 Work Days Only » Submit RFQ with complete commercial terms |

|

Sample Making

|

Sample Order → Engineering Review → Sample Plan to Customer → Sample Status Tracking → Submit Samples with Doc.

» Tooling L/T: 2-4 wks. Sample L/T: 2 wks » Continuous Sample Status Tracking » Complete Documents for sample approval |

|

Order Management

|

CRM System → Open Order Confirm → Logistic Arrangement.

» Production L/T: 2-4 wks » Weekly Open Order Confirm » Preferred 3PL Service to Customers |

|

Quality Control

|

Certificates: RoHS, 1809001:2015, SGS.

IQC → IPQC → OQC/FQC → Quality Complain Feedback → Audit & Training. » Plant Audit and Qualified by world famous company » Strict Quality Management Procedure with Traceability |

|

Application

|

Aerospace/ Marine/ Metro/ Motorbike/ Automotive industries. Instruments & Meters. Office equipments, Home appliance. Medical

equipments, Telecommunication, Electrical & Electronics, Fire detection system, etc. |

Picture case

Often ask questions

What parts can you buy from Bergek?

CNC machining milling parts/turning parts, stamping parts, sheet metal processing parts, bending parts

Why should you buy from Bergek instead of another vendor?

Focus on CNC processing and sheet metal processing, provide CNC turning, CNC milling, stamping bending, sheet metal manufacturing one-stop solution.

Can Bergek make the blueprints for me?

We do not provide design services. You are responsible for submitting 2D and 3D CAD drawings and then we can provide a manufacturing design review upon receipt of your order.

Bergek is a world-class manufacturing service provider in Shenzhen. We have advanced equipment to provide a full range of custom products to manufacturers around the world, focusing on CNC machining and sheet metal processing. Our goal is to make it easier to customize parts. So why not come and see our facilities for yourself? We stand ready to help you bring your next product to market, let us help you succeed! Please contact us with your inquiry.

click request quotation

Related Keywords