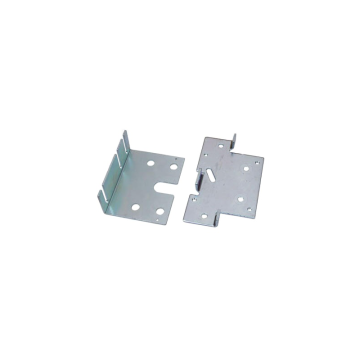

Custom Made Sheet Metal Bending Parts

-

$6.00≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- ShenZhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 8000000 |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | IOS9001 |

| HS Code: | Non |

| Transportation: | Ocean,Land,Air |

| Port: | ShenZhen |

Bending is one of the most common sheets metal manufacturing operations. Also known as bending, flanging, die bending, folding, and trimming, this method is used to deform materials into angular shapes.

Bending method

There are quite a few different bending methods available. Each approach has its own advantages. The usual dilemma is between precision and simplicity, and the latter is used more often. The simple approach is more flexible and, most importantly, requires fewer different tools to get a result.

V-shaped bending

V-bending is the most common bending method using punches and dies. It is divided into three subgroups - base, air bending, and stamping. Air bending and underlaying account for about 90% of all bending work.

U-shaped bending

A U-bend is very similar in principle to a V-bend. There's a die and a punch, and this time they're both U-shaped, creating a similar bend. For example, this is a very simple method of bending steel U-channel steel, but it is not common because such profiles can also be produced using other, more flexible methods.

Ladder bending

Step bends are essentially repeated V bends. Also known as bump bending, this method uses many v-shaped bends in succession to get a larger radius for your workpiece. The final mass depends on the number of bends and the steps between them. The more you have, the smoother the results.

|

Custom Precision Sheet Metal Fabrication Parts |

|

|

Quotation |

According to your drawing(size, material, thickness, processing content, and required technology, etc) |

|

Material |

Carbon steel, SPCC, SGCC, Stainless steel, Aluminum, Brass, Copper, etc. |

|

Processing |

Laser Cutting, Precision Stamping, Bending, CNC Punching, Threading, Riveting, Drilling, Welding etc |

|

Surface Treatment |

Brushing, Polishing, Anodizing, Powder Coating, Plating, Silkscreen printing, Sandblast, etc |

|

Tolerance |

+/-0.2mm, 100% QC quality inspection before delivery, can provide quality inspection form |

|

Logo |

Silk print, Laser marking. |

|

Size |

Accept custom size. |

|

Color |

White, black,silver, red, grey, Pantone and RAL, etc |

|

Drawing format |

DWG, DXF, STEP, IGS, 3DS, STL, SKP, AI,PDF, JPG, Draft. |

|

Sample lead time |

No surface treatment, 1-3 workdays. Require surface treatment, 3-5 workdays. |

|

Pricing Term |

EXW, FOB, CIF, etc |

|

Payment term |

Sample: 100% payment before production Mass production: (50% in advance as deposit, balance before delivery) |

|

Certificate |

ISO9001:2015/SGS/TUV/RoHS |

|

Packing |

By carton or as your request |

Often ask questions

What parts can you buy from Bergek?

CNC machining milling parts/turning parts, stamping parts, sheet metal processing parts, bending parts

Why should you buy from Bergek instead of another vendor?

Focus on CNC processing and sheet metal processing, provide CNC turning, CNC milling, stamping bending, sheet metal manufacturing one-stop solution.

Can Bergek make the blueprints for me?

We do not provide design services. You are responsible for submitting 2D and 3D CAD drawings and then we can provide a manufacturing design review upon receipt of your order.

Bergek is a world-class manufacturing service provider in Shenzhen. We have advanced equipment to provide a full range of custom products to manufacturers around the world, focusing on CNC machining and sheet metal processing. Our goal is to make it easier to customize parts. So why not come and see our facilities for yourself? We stand ready to help you bring your next product to market, let us help you succeed! Please contact us with your inquiry.

click request quotation

Related Keywords