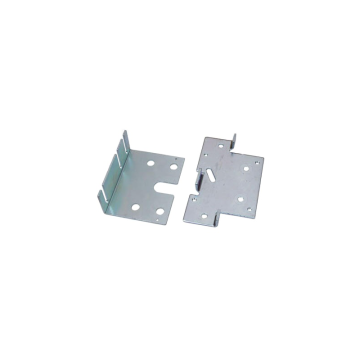

custom sheet metal bending process

-

$6.00≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- ShenZhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 8000000 |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | IOS9001 |

| HS Code: | Non |

| Transportation: | Ocean,Land,Air |

| Port: | ShenZhen |

Bending principle: refers to the sheet metal parts do straight edge, hypotenuse, bending and other shapes, such as bending sheet metal parts into L shape, U shape, V shape, etc.

Die bending: generally used for complex shape, small size, large output of sheet metal products.

Bending machine bending: generally used for large product size, small batch production of sheet metal products.

(1) minimum bending radius of sheet metal bending parts

When the material is bent, the outer layer is stretched and the inner layer is compressed at the rounded corners. When the thickness of the material is constant, the smaller the inner fillet is, the more serious the tensile and compression of the material is. When the tensile stress of the outer fillet exceeds the ultimate strength of the material, cracks and fractures will occur. If the bending fillet is too large, it will be affected by the material rebound, and the accuracy and shape of the product can not be guaranteed.

(2) straight edge height of bending parts

The straight edge height of bending parts can not be too small, otherwise, it is difficult to achieve the precision requirements of the product.

(3) the smallest edge margin of the bending piece.

There are two ways to process the holes on the bending parts, one is to bend first and punch holes; The other is punching and bending. Bending first after punching margin design according to the requirements of punching pieces; Punching after bending should let the hole in the bending deformation zone, otherwise, it will cause the deformation of the hole and the opening of the crack

(4) When bending the adjacent edge close to the rounded corner, the curved edge should be kept a certain distance from the rounded corner

(5) Process gap design of bending parts

If a side is only partially bent, in order to prevent cracking and deformity, it should be designed with a process notch, the width of the process notch is not less than 1.5t, the depth of the process notch is not less than 2.0t+R, where T is the sheet metal thickness

(6) the design of bending parts.

The bending side refers to the bending side and the bottom side parallel, commonly known as the dead side. The previous process of beating the edge is to bend the bending edge into a certain Angle, and then beat and fit.

(7) Process hole design of bending parts

U-shaped bending parts in the design, two curved edges as long as the best, in order to avoid bending when migration and produce waste products, if you don't allow both sides as long for structure design, in order to ensure the accurate location in the mold of products, should be added when the design process in advance positioning hole, especially bending forming parts for many times, must design process hole for the locating datum, in order to reduce the accumulated error, Ensure product quality

Often ask questions

What parts can you buy from Bergek?

CNC machining milling parts/turning parts, stamping parts, sheet metal processing parts, bending parts

Why should you buy from Bergek instead of another vendor?

Focus on CNC processing and sheet metal processing, provide CNC turning, CNC milling, stamping bending, sheet metal manufacturing one-stop solution.

Can Bergek make the blueprints for me?

We do not provide design services. You are responsible for submitting 2D and 3D CAD drawings and then we can provide a manufacturing design review upon receipt of your order.

Bergek is a world-class manufacturing service provider in Shenzhen. We have advanced equipment to provide a full range of custom products to manufacturers around the world, focusing on CNC machining and sheet metal processing. Our goal is to make it easier to customize parts. So why not come and see our facilities for yourself? We stand ready to help you bring your next product to market, let us help you succeed! Please contact us with your inquiry.

click request quotation

Related Keywords