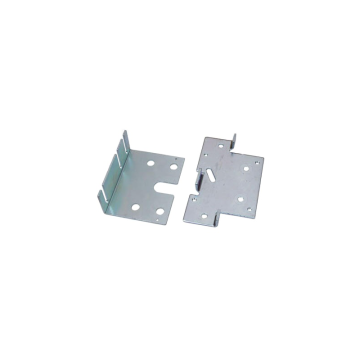

sheet metal bending box

-

$6.00≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- ShenZhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 8000000 |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | IOS9001 |

| HS Code: | Non |

| Transportation: | Ocean,Land,Air |

| Port: | ShenZhen |

Selection of materials

Sheet metal processing materials commonly used are cold-rolled sheet (SPCC), hot-rolled sheet (SHCC), galvanized sheet (SECC, SGCC), copper (CU) brass, red copper, beryllium copper, aluminum plate (6061, 6063, hard aluminum, etc.), aluminum profiles, stainless steel (mirror, drawing surface, fog surface), according to the different role of the product, the selection of materials, Generally, the use and cost of the product should be considered.

1. SPCC cold-rolled sheet, mainly used in electroplating and paint parts, low cost, easy molding, material thickness ≤3.2mm.

2. Hot rolled plate SHCC, material T≥3.0mm, also used electroplating, paint parts, low cost, but difficult to form, mainly used flat parts.

3. Galvanized sheet SECC, SGCC. SECC electrolytic plate N material, P material, N material is not mainly surface treatment, high cost, P material for spraying parts.

4. Copper; Mainly with conductive materials, its surface treatment is nickel plating, chromium plating, or no treatment, high cost.

5. Aluminum plate; General surface chromate (J11-A), oxidation (conductive oxidation, chemical oxidation), high cost, silver plating, nickel plating.

6. Aluminum profile; Materials with complex cross-section structures are widely used in various boxes. Surface treatment with aluminum plate.

7. Stainless steel; Mainly used without any surface treatment, high cost.

The common surface treatment process of the sheet metal:

1. Electroplating: in an electroplating solution, charged ions are attached to the surface of the product under the action of an electric field to form a coating.

2. Powder spraying: the powder is polarized, under the action of electric field force, evenly attached to the product surface of opposite polarity.

3. Electrophoretic coating: Under the action of Yin and Yang poles, charged coating ions move to the surface of the product and deposit to form a coating.

4. Dipping: the product is heated in the molten material, and the heated metal is combined with the surrounding molten material to form a surface material of a certain thickness.

Often ask questions

What parts can you buy from Bergek?

CNC machining milling parts/turning parts, stamping parts, sheet metal processing parts, bending parts

Why should you buy from Bergek instead of another vendor?

Focus on CNC processing and sheet metal processing, provide CNC turning, CNC milling, stamping bending, sheet metal manufacturing one-stop solution.

Can Bergek make the blueprints for me?

We do not provide design services. You are responsible for submitting 2D and 3D CAD drawings and then we can provide a manufacturing design review upon receipt of your order.

Bergek is a world-class manufacturing service provider in Shenzhen. We have advanced equipment to provide a full range of custom products to manufacturers around the world, focusing on CNC machining and sheet metal processing. Our goal is to make it easier to customize parts. So why not come and see our facilities for yourself? We stand ready to help you bring your next product to market, let us help you succeed! Please contact us with your inquiry.

click request quotation

Related Keywords