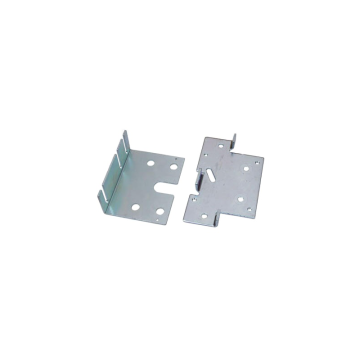

Stainless Sheet Metal Bending

-

$6.00≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- ShenZhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 8000000 |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | IOS9001 |

| HS Code: | Non |

| Transportation: | Ocean,Land,Air |

| Port: | ShenZhen |

What are the process designs in sheet metal bending?

Hole margin: there are two kinds of hole processing methods for the bending parts, one is first bending after punching, and the other is first punching after bending. The former only needs to design the hole margin according to the requirements of punching and cutting parts; The latter needs to determine the hole margin first to ensure that the hole position is outside the deformation zone, otherwise, it will cause the deformation of the hole and crack at the opening. The minimum hole margin should be greater than or equal to the sum of the bending radius and the material thickness.

Specifications:

1.OEM & ODM

2.High Quality & Precision

3.Competitive Price

4.Large Quantity Production Capacity

5.Short Delivery Time

6.RoHS Compliant

7.Optional Materials:Aluminum,Brass,Copper,Stainless Steel etc

8.Specification Is Customize

9.LOGO Can Be Customized

10.Processing Type:Metal Stamping Bending Parts,Metal Stamping Drawing Parts,Metal Stamping Parts

11.Samples: Stamping Hand Samples Are Available To Reduce Costing

Our promise:

1.Offering design and improvement scheme freely.

2.Offering video and photos with details freely during production.

3.Helping customers to do factory inspection freely for his other Chinese suppliers.

4.Helping customers lacking money to apply for Alibaba finacing.

5.Producing completely according to the accuracy of drawings,assembly measurement to detect function and strict quality control to ensure 0 return rate.

6.99% orders can be ensured delivery time.

7.Quote can be offered within 2 days fastest

8.Delivery time is only 7 days fastest.

9.Responding to the enquiry within 2 hours.

10.The materials we use are optimal.

11.24 hours online service.

12.The lowest price with the same quality and service.

13.Logistics arrangement with high performance to price ratio.

14.The most suitable packing method to different products.

Often ask questions

1. Are you a trading company or a manufacturer?

A: We are A manufacturer specializing in hardware parts production for many years. Our main products include CNC machining parts, hardware stamping parts, and so on. We provide OEM and ODM services.

2.What's your delivery date?

A: The delivery date is 15~20 days after receipt of payment.

3. What are the materials of your products?

A: The materials we use in our products are environmentally friendly and safe.

4.What are your terms of payment?

A:30%~50% deposit, balance before delivery.

5. How about the quality of your products?

A: 100% quality inspection before delivery

click request quotation

Related Keywords