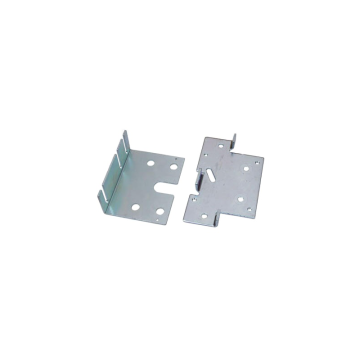

Sheet Metal Bending High Precision Custom

-

$6.00≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- ShenZhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 8000000 |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | IOS9001 |

| HS Code: | Non |

| Transportation: | Ocean,Land,Air |

| Port: | ShenZhen |

Sheet metal processing is a key technology that sheet metal technicians need to master, and also an important process of sheet metal product forming. Sheet metal processing includes traditional cutting blanking, blanking, bending stamping, and other methods and process parameters, as well as a variety of cold stamping, die structure and process parameters, the working principle, and operation methods of various equipment, and new stamping process and process. Parts sheet metal processing is called sheet metal processing. So, what are the technical characteristics of sheet metal processing?

1. Sheet metal processing power density is high: workpiece absorption sheet metal processing rapidly rising temperature and melting or vaporization, and even high melting point, high hardness, high brittle materials (such as ceramics, diamond, etc.). Can also be processed with sheet metal;

2. Sheet metal processing beam is easy to control: easy to combine with precision machinery, precision measurement technology, electronic computer, to achieve high automation, high processing accuracy;

3. Sheet metal processing is convenient and flexible: the robot can process sheet metal in a harsh environment or places that are difficult for others to enter.

4. Sheet metal processing application range is wide: sheet metal processing beam divergence Angle can be less than 1 milliradian, spot diameter can be small to the micron, action time can be shortened to nanoseconds and picoseconds. At the same time, the continuous output power of high-power sheet metal processing can reach the kilowatt to ten-kilowatt order of magnitude. As there are many welding methods used in industrial production, they can be divided into three categories according to the characteristics of the welding process.

Specifications:

1.OEM & ODM

2.High Quality & Precision

3.Competitive Price

4.Large Quantity Production Capacity

5.Short Delivery Time

6.RoHS Compliant

7.Optional Materials:Aluminum,Brass,Copper,Stainless Steel etc

8.Specification Is Customize

9.LOGO Can Be Customized

10.Processing Type:Metal Stamping Bending Parts,Metal Stamping Drawing Parts,Metal Stamping Parts

11.Samples: Stamping Hand Samples Are Available To Reduce Costing

Our promise:

1.Offering design and improvement scheme freely.

2.Offering video and photos with details freely during production.

3.Helping customers to do factory inspection freely for his other Chinese suppliers.

4.Helping customers lacking money to apply for Alibaba finacing.

5.Producing completely according to the accuracy of drawings,assembly measurement to detect function and strict quality control to ensure 0 return rate.

6.99% orders can be ensured delivery time.

7.Quote can be offered within 2 days fastest

8.Delivery time is only 7 days fastest.

9.Responding to the enquiry within 2 hours.

10.The materials we use are optimal.

11.24 hours online service.

12.The lowest price with the same quality and service.

13.Logistics arrangement with high performance to price ratio.

14.The most suitable packing method to different products.

Often ask questions

What parts can you buy from Bergek?

CNC machining milling parts/turning parts, stamping parts, sheet metal processing parts, bending parts

Why should you buy from Bergek instead of another vendor?

Focus on CNC processing and sheet metal processing, provide CNC turning, CNC milling, stamping bending, sheet metal manufacturing one-stop solution.

Can Bergek make the blueprints for me?

We do not provide design services. You are responsible for submitting 2D and 3D CAD drawings and then we can provide a manufacturing design review upon receipt of your order.

Bergek is a world-class manufacturing service provider in Shenzhen. We have advanced equipment to provide a full range of custom products to manufacturers around the world, focusing on CNC machining and sheet metal processing. Our goal is to make it easier to customize parts. So why not come and see our facilities for yourself? We stand ready to help you bring your next product to market, let us help you succeed! Please contact us with your inquiry.

click request quotation

Related Keywords