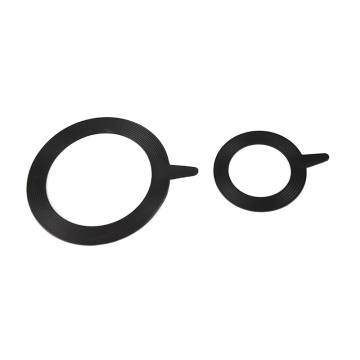

peek shaft sleeve plastic

-

$6.50≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- ShenZhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 800000 |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| HS Code: | NON |

| Transportation: | Ocean,Land,Air |

| Port: | ShenZhen |

PEEK resin is a kind of special engineering plastic with good performance. Compared with other special engineering plastics, PEEK resin has many significant advantages, such as high-temperature resistance, good mechanical properties, good self-lubrication, chemical corrosion resistance, flame retardant, peel resistance, and radiation resistance, stable insulation, hydrolysis resistance, and easy processing. It is recognized as a thermoplastic material with high comprehensive performance in harsh environments.

PEEK is a material that has appeared frequently on major search engines in recent years. There are two reasons: first, PEEK has been widely used in the application field, with the continuous innovation of product performance and the continuous decline of the price. PEEK has moved from its beginnings in the aerospace industry, replacing aluminum and other metals in making various aircraft parts. Up to now, in machinery, electronics, chemical, automobile, and other high-tech industrial fields, according to the required specifications of the industry, manufactured parts are applied to them, not only the product performance has been significantly improved, the price is less than metal products. Second, the research on special plastics has been broken in China. PEEK manufacturers not only meet the domestic demand but also export to foreign countries, breaking the previous PEEK production and supply technology monopolized by foreign countries.

The increasing use of PEEK is closely related to product features. PEEK material is the main properties as follows:

1, temperature resistance, good thermal stability, very high heat resistance, HDT above 315 degrees Celsius, UL continuous use temperature of 260 degrees Celsius.

2. Mechanical properties PEEK is plastic with a balance of toughness and rigidity. In particular, its excellent fatigue resistance to alternating stress is superior in all plastics, comparable with alloy materials.

3, self-lubricating PEEK has outstanding sliding characteristics in all plastics, suitable for strict requirements of low friction coefficient and wear resistance applications. In particular, carbon fiber and graphite mixed modified PEEK have better self-lubrication performance.

4, chemical resistance (corrosion resistance)PEEK has good chemical resistance. Of the usual chemicals, the only one that can dissolve or destroy it is concentrated sulfuric acid, which has similar corrosion resistance to nickel steel.

5,PEEK is a very stable polymer, 1.45mm thick sample, without any flame retardant can reach a higher flame retardant standard.

6, peel resistance PEEK has good peel resistance, so it can be made into thin coated or electromagnetic wire and can be used under harsh conditions.

7, radiation resistance high radiation resistance ability is very strong, more than the better radiation resistance of polystyrene in general resin. γ irradiation dose up to 1100Mrad can still maintain good insulation performance.

8, hydrolysis resistance PEEK and its composite materials are not affected by the chemical effects of water and high-pressure water vapor, the products made of this material can still maintain good characteristics in high temperature and high-pressure water continuous use.

With the deepening of PEEK research, more and more properties have been discovered, and the application fields are also expanding. In recent years, PEEK material has been widely used in the field of health, replacing the inherent metal with the high-performance health grade polymer material PEEK.

PEEK is a material that has appeared frequently on major search engines in recent years. There are two reasons: first, PEEK has been widely used in the application field, with the continuous innovation of product performance and the continuous decline of the price. PEEK has moved from its beginnings in the aerospace industry, replacing aluminum and other metals in making various aircraft parts. Up to now, in machinery, electronics, chemical, automobile, and other high-tech industrial fields, according to the required specifications of the industry, manufactured parts are applied to them, not only the product performance has been significantly improved, the price is less than metal products. Second, the research on special plastics has been broken in China. PEEK manufacturers not only meet the domestic demand but also export to foreign countries, breaking the previous PEEK production and supply technology monopolized by foreign countries.

FAQ

Q1:Will we Wo sign Non-Disclosure Agreements(NDA) ?

A:Yes.If it gives you peace-of-mind to sign an NDA,we are more than w ling to do so.But we have the rightkeep your design in confidential no matter NDA is signed or not.All factories are camera monitored.

Q2:How do I get a quote?

A:Please kindly provide us 3D or CAD solid model in Step, IGS,X_T format, normally Two-dimensional(2D)drawings are not adequate for accurate quoting or parts making B.Please tell us your requirement on quantisurface treatment.Color material,application enviranment for accurate pricing.

Q3:How quickly can l get my parts?

A:Quality parts can be made in 3-5 days if you provide us with complete 2Dand3DCAD models.Morecomplex parts requiring or other special features will take longer.As for shipping,most of our shipments arevia DHL, UPS,Fedex,which can take a few days from China to Europe or NorthAmerica.

Q4;How you do the quality control?

A: a.Materials inspection by IQC.

b.The fist sample inspected by QC,QC wild o over check as per the parameters list and critical dimensic requested by customers, to decide if it can go ahead for production.

c.During processing# our IP QC will check the injection molded parts every 2 hours,ensure no any rejects.

d.FQC will check the products before sending to the warehouse.

e.100% inspected by O QC before shipping out.

Related Keywords