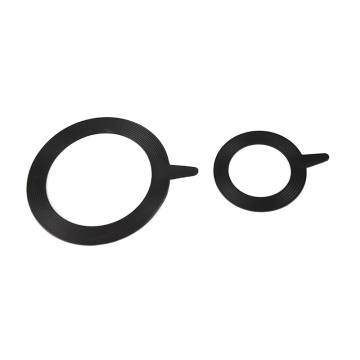

peek sector gear product custom

-

$6.50≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- ShenZhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 800000 |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| HS Code: | NON |

| Transportation: | Ocean,Land,Air |

| Port: | ShenZhen |

PEEK material:

Polyether etherketone can be used at very high tmperatures(about+260°C) and it

shows an extraordinary mechanical strength,thoughness,hardness,flexural strength,

PEEK exhibits excellent chemical resistance, very good dielectric properties up to

+260°C and a very good resistance to all kinds of radiation(even ultraviolet rays only

lead to a slight yellow discolouration of its self-extinguishing properties according to UL 94.

Product Descriptions:

| Item: | peek plastic moulding injection gears |

| Color: | Nature, black. |

| Material: | PEEK, PEEK CA30, PEEK CF30 |

| Size: | OEM is welcome. |

| Weigth: | 0.5~500g |

| Process: | CNC machining or molding injection |

Characteristics:

* Strong and stiff plastic

* Outstanding chemical resistance

* Good mechanical properties at elevated temperatures

* Resistant to hot water and steam

* Bearing grade PEEK has excellent wear characteristics

* UL 94 V-0 flammability rating

* Very low smoke and toxic gas emissions when exposed to flame

Typical Applications:

* Semiconductor machinery components

* Pump and valve seals, components

* Electrical components, Insulation parts

* The surgical and dental equipments that required repeat using and sterilization, and body parts

* Food processing machinery components.

Advantages of PEEK:

1. Lower fuel consumption and environmental impact with lighter solutions;

2. Improve component life through elastic performance in a wide temperature range;

3. Enhanced durability and excellent wear resistance of components;

4. Reduce downtime and component failures to resist harsh chemicals and natural elements;

5. Relying on long-term mechanical properties and dimensional stability;

6. Meet strict safety requirements, with low fire, smoke, and toxic emissions;

7. Greater component integrity due to excellent barrier performance on fluids and gases.

FAQ

Q1:Will we Wo sign Non-Disclosure Agreements(NDA) ?

A:Yes.If it gives you peace-of-mind to sign an NDA,we are more than w ling to do so.But we have the rightkeep your design in confidential no matter NDA is signed or not.All factories are camera monitored.

Q2:How do I get a quote?

A:Please kindly provide us 3D or CAD solid model in Step, IGS,X_T format, normally Two-dimensional(2D)drawings are not adequate for accurate quoting or parts making B.Please tell us your requirement on quantisurface treatment.Color material,application enviranment for accurate pricing.

Q3:How quickly can l get my parts?

A:Quality parts can be made in 3-5 days if you provide us with complete 2Dand3DCAD models.Morecomplex parts requiring or other special features will take longer.As for shipping,most of our shipments arevia DHL, UPS,Fedex,which can take a few days from China to Europe or NorthAmerica.

Q4;How you do the quality control?

A: a.Materials inspection by IQC.

b.The fist sample inspected by QC,QC wild o over check as per the parameters list and critical dimensic requested by customers, to decide if it can go ahead for production.

c.During processing# our IP QC will check the injection molded parts every 2 hours,ensure no any rejects.

d.FQC will check the products before sending to the warehouse.

e.100% inspected by O QC before shipping out.

Related Keywords