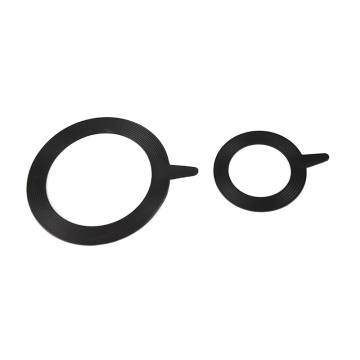

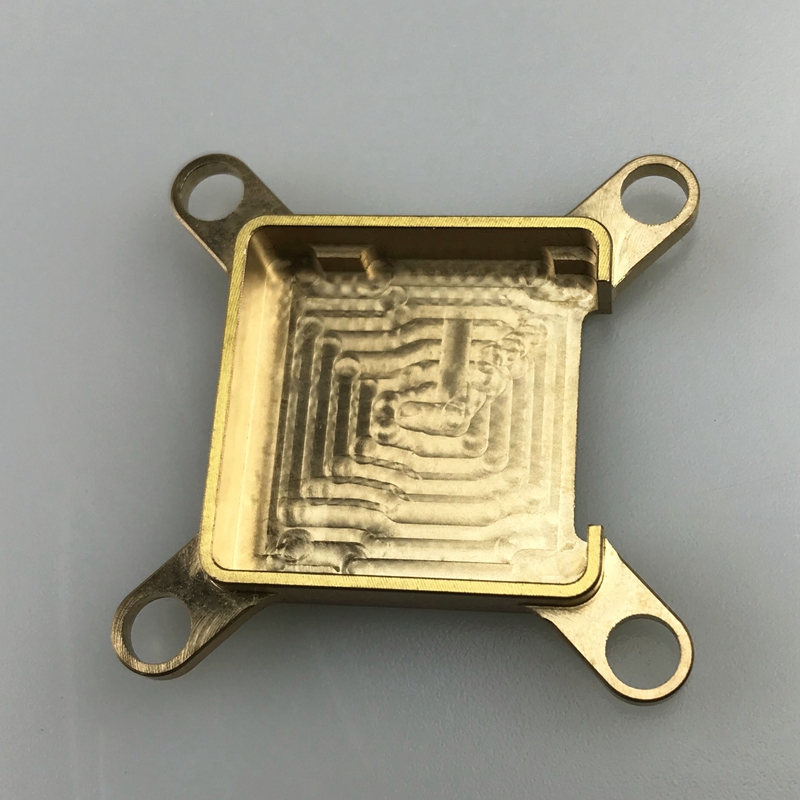

Customized cnc machining parts

-

$5.00≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Express, Air

- Port:

- Guangdong, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | shenzhen |

|---|---|

| Productivity: | 1000 |

| Supply Ability: | 1000 |

| Payment Type: | T/T,Paypal |

| Incoterm: | CFR,FOB,CIF,EXW,FCA,DDP,DDU,Express Delivery |

| Certificate: | ISO9001 |

| HS Code: | Non |

| Transportation: | Ocean,Land,Express,Air |

| Port: | Guangdong,Shenzhen |

What is machining service?

Numerical control machining (numerical control machining) refers to a process method for machining parts on CNC machine tools. The process rules of CNC machine tool processing and traditional machine tool processing are generally consistent, but there have also been significant changes. A machining method that uses digital information to control the displacement of parts and tools. It is an effective way to solve the problems of variable variety of parts, small batches, complex shapes, and high precision, and to achieve high-efficiency and automated processing.

Once your order is confirmed, we will review your design and provide a design for manufacturing review, pointing out any areas where we may not be able to achieve your desired tolerances. It’s helpful if you can specify which areas in your design have critical tolerances that must be met and which can be slightly modified if needed to reduce the time and costs involved. General Tolerances to DIN ISO 2768 for CNC machining in metal and plastic also as sheet metal parts.

Item:Customized Precision CNC Machining Service

Material:

1.Stainless Steel Alloy: 303 / 304 / 316 / 412 / etc.

2.Steel Alloy:l: Carbon Steel / Die Steel / Spring Steel etc.

3.Brass Alloy: 3602 / 2604 / H59 / H62 / etc.

4.Bronze:C51000, C52100,C54400 etc

5.Iron: 1213, 12L14,1215 etc

6.Aluminum Alloy: 5052 /6061/ 6063 / 2017 / 7075 / ADC12/518 etc.

Other Special Materials: Lucite / Nylon / Bakelite / POM / ABS / PP / PC / PE / PEEK / Titanium etc.

Surface treament:Anodize, Plating, Brushing, Polishing, Blackened, Powder coating, Sandblasting, Laser engraving etc.

Tolerance:±0.005mm

Equipment:CNC centre,CNC lathe,General lathe,General Milling, CNC milling, Drilling machine, internal grinder.Cylindrical grinder machine,centerless grinder machine & other equipments.

Standard:Our factory are specialized in the production of Non-standard products.

Our advantages

* Good service

We will get back to you within 1 hour and quote to you within 24 hours. We can manufacture non-standard parts according to your drawings. We offer the best after-sales service.

* Reasonable Price

Our prices are reasonable and competitive if you compare with other manufacturers.

* Perfect quality

We have strict quality control from production to delivery. Our company has strong technical support. We have trained a group of managers who are familiar with product quality and good at modern management concepts.

* Flexible Lead time

When quoting, we will provide you with a suitable delivery date. If the project is urgent, we can set a faster delivery date for free according to the actual situation.

End: Merchants who need customized products can send drawings to szbergek for quotation, click request quotation

FAQ:

Q1.What is your service?

A1:Our main services are CNC machining,sheet metal fabrication and plastic injection.

Q2. How to ensure the product quality.

A2:We have QC department.When the parts are ready,we will arrange inspection for the parts to make the parts are no problem before shipping.Also,we can send you product pictures before shipping for your confirmation.

Q3.How long is your delivery time?

A3:We have flexible delivery time.Urgent project match urgent production.General delivery time is 7-15 working days.

Q4. What is your payment method?

A4:30% value of T/T in advance and other 70% balance on B/L copy.

For order less than 5000USD, would suggest you pay 100% in advance to reduce the bank charges.

Q5: How to deal with the faulty?

A5: Firstly, Our products are produced in strict quality control system and the defective rate will be less than 1%. Secondly, If the parts you received are wrong by our mistakes,we will re-make them for you.Finally,if you received the wrong parts and you don't want us to re-make new parts for you,we can refund you the cost for the order.

Related Keywords