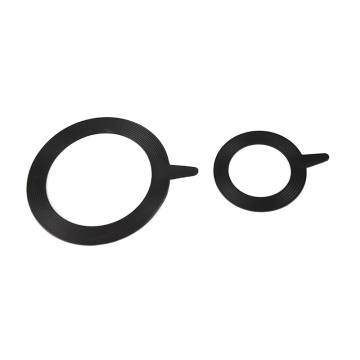

High precision 5 axis CNC machining service

-

$3.00≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Guangdong, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | shenzhen |

|---|---|

| Productivity: | 1000 |

| Supply Ability: | 1000 |

| Payment Type: | T/T |

| Incoterm: | CFR |

| Certificate: | ISO9001 |

| HS Code: | Non |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Guangdong,Shenzhen |

CNC Machining Applications:

Rapid Tooling:

CNC machining can cut a high variety of fully dense, durable materials such as aluminum 5052 and stainless steel, it is perfect for creating fixtures or molds.

Rapid Prototyping:

The range of affordable metal alloys (like aluminum 6061) and plastics (like acetal or ABS) combined with the speed of our skilled machinists makes it a great option for prototyping.

End-Use Production:

Performance-enhancing finishes, precision tolerances as low as +/- 0.005mm, and certifiable material options make CNC machining an excellent technology for end-use parts.

CNC processing advantages: CNC can process a variety of materials, each material has a variety of choices, the limiting factor is only whether it can be processed. After CNC treatment, the mechanical properties of the prototype are almost the same as those of the raw material. CNC machining tolerances are small. CNC surface finish is better. For tolerances and smoothness alone, CNC is definitely the best choice. However, consider the combination of cost, manpower, and lead time.

Product details:

CNC Machining or Not:Cnc Machining

Type:Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping

Material Capabilities:Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys

Micro Machining or Not:Micro Machining

Place of Origin:China

Point of origin:Guangdong

Model Number:OEM

Brand Name:szbergek

Material:Aluminum

Process:CNC Machining

Surface Treatment:Anodizing/ Chroming/ Polishing

Tolerance:0.005 mm

Size:Customized Size

Color:Customized Color

Drawing Format:DWG/ STEP/ PDF

Our advantages

* Good service

We will get back to you within 24 hours. We can manufacture non-standard parts according to your drawings. We offer the best after-sales service.

* Reasonable price

Our prices are reasonable and competitive with those of other manufacturers.

* Perfect quality

We have strict quality control from production to delivery. Our company has strong technical support. We have trained a group of managers who are familiar with product quality and good at modern management concepts.

* Flexible Lead time

When quoting, we will provide you with a suitable delivery date. If the project is urgent, we can set a faster delivery date for free according to the actual situation.

End: Merchants who need customized products can send drawings to szbergek for quotation, click request quotation

Related Keywords