CNC Machining 3D Printing Service

-

$6.00≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean

- Port:

- Guangdong, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | shenzhen |

|---|---|

| Productivity: | 1000 |

| Supply Ability: | 1000 |

| Payment Type: | T/T |

| Incoterm: | CFR |

| Certificate: | ISO9001 |

| HS Code: | Non |

| Transportation: | Ocean |

| Port: | Guangdong,Shenzhen |

CNC machining or computer numerical control machining is a common reduction manufacturing technique that uses a series of complex machines such as grinders, lathes, drills, routers, plasma cutters, laser cutters, and milling machines to remove excess parts from raw materials and create molded precision CNC machined parts. CNC processing covers CNC milling, CNC turning, CNC drilling, and other services.

CNC machining and 3D Printing - The difference between 3D printing and CNC machining

There are some similarities and differences between 3D printing and CNC machining. The main differences between them are material, size, speed, cost, production, scale, waste, etc.

Materials. CNC is mainly metal processing but also processing plastics, thermoplastics, acrylic resins, softwood and hardwood, molding foam, and wax. 3D printing is mainly used for plastics and, to a lesser extent, metals. Some technologies can produce parts from ceramics, wax, sand, and composite materials. 3D printers can't use every material used by traditional manufacturers because a high melting point can deform the metal. And a separate 3D printer for each material.

Commonly used CNC processing materials - Plastic: ABS, nylon, polycarbonate, PEEK; Metals: aluminum, stainless steel, titanium, brass, alloy

Commonly used 3D printing materials -- plastics: nylon, PLA, ABS, ULTEM, ASA, TPU, resin; Metals: aluminum, stainless steel, titanium

Speed. CNC can be produced faster than 3D printing. 3D printing requires building the final product layer by layer, and automated CNC machines can work for long periods of time without interruption as long as they are properly maintained. One hour of CNC work is equivalent to several hours of 3D work. 3D-printed products also need to be worked on after construction, such as cleaning, polishing, and sealing.

Size. Various sizes can be produced by CNC machining, whether it is a small part of a refrigerator. In 3D printing, there are some limitations on the size. The part cannot be larger than the printing bed.

CNC processing is a wood reduction process that ends up producing some non-recyclable waste, which makes cleaning up more difficult. 3D printing, on the other hand, uses only the materials needed for the process, controls the quantity precisely, doesn't produce much waste, and doesn't need to be cleaned up.

Quality. No matter what material is used, CNC machines can produce high-precision parts with better tolerances than 3D printers. Good manufacturers can provide products with 0.01mm accuracy.

Versatility. CNC produces tools, fixtures, and a wide range of custom parts, with thousands of identical parts or one-off prototypes available for a variety of industries. 3D printing is limited in terms of materials, sizes, and types.

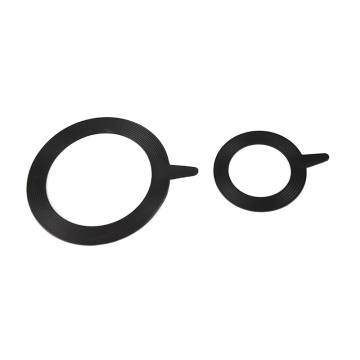

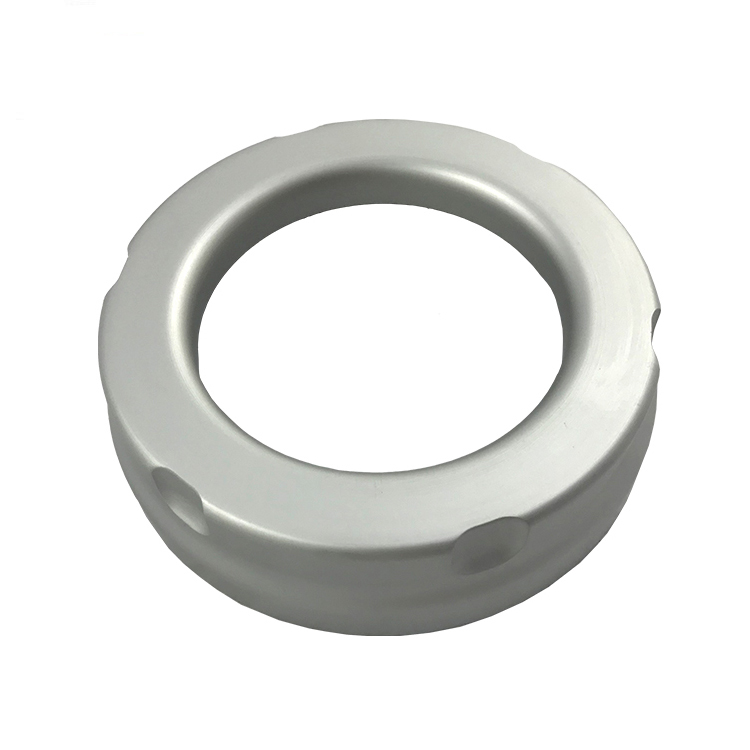

Product details:

CNC Machining or Not:Cnc Machining

Type:Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping

Material Capabilities:Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys

Micro Machining or Not:Micro Machining

Place of Origin:China

Point of origin:Guangdong

Model Number:OEM

Brand Name:szbergek

Material:Aluminum

Process:CNC Machining

Surface Treatment:Anodizing/ Chroming/ Polishing

Tolerance0.005 mm

Size:Customized Size

Color:Customized Color

Drawing Format:DWG/ STEP/ PDF

End: Merchants who need customized products can send drawings to szbergek for quotation, click request quotation

Related Keywords