mini custom pc keyboard

-

$10.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express, Others

- Port:

- Guangdong, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | shenzhen |

|---|---|

| Productivity: | 1000 |

| Supply Ability: | 10000 |

| Payment Type: | L/C,T/T,D/P,D/A,Paypal,Others |

| Incoterm: | FOB,CFR,CIF,Express Delivery,DAF,DES,EXW,FAS,FCA,CPT,CIP |

| HS Code: | Non |

| Transportation: | Ocean,Land,Air,Express,Others |

| Port: | Guangdong,Shenzhen |

Mechanical keyboard structure includes keycap, mechanical shaft, and shell three parts, mechanical shaft is the core of the mechanical keyboard, is the key of the mechanical keyboard, different shafts have a different key feel, mechanical keyboard shell is usually made of aluminum alloy and plastic material, this shell can be processed by CNC.

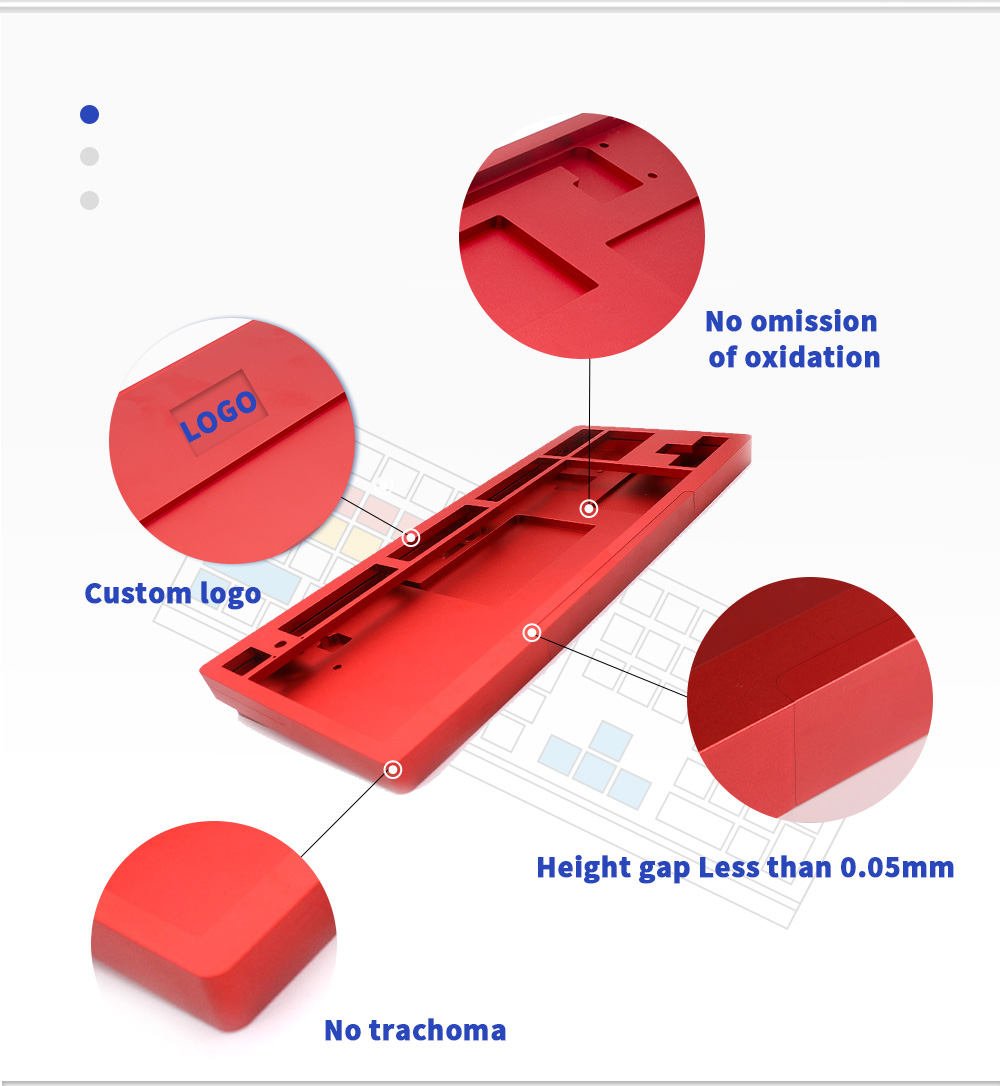

Matters needing attention in processing aluminum shell of CNC mechanical keyboard:

1. First of all, we choose appropriate materials for processing, to ensure a good feel and appearance of the mechanical keyboard,

2, processing matters needing attention: considering the product volume and processing time, we choose 20 milling cutters in the adjustment stage, increase the z-axis feed quantity, so that the processing efficiency can be improved by 30%; And in order to ensure the surface quality of the aluminum shell of the mechanical keyboard, minimize the surface knife marks and joint marks, we reduce the number of knife connections, the R Angle of the art line is micro rounded, and the PCD polishing knife is used for one-time processing.

3. After processing the aluminum shell of the mechanical keyboard, this is only a semi-finished product. We need to manually use a sponge to clean the acute Angle, prevent the acute Angle from being wiped flat after oxidation, and avoid the oxidation layer falling off.

4. In addition, clean with water to prevent corrosion of cutting fluid.

Details of customized products:

Customization: Welcome customization, send drawings to us.

Make you want to do the unique thing you want to do, make your beautiful dream come true.

According to customer requirements, flexible and rapid temporary deployment to meet as far as possible, accept your special needs, so that you save time and worry.

Material: aluminum alloy: brass alloy, stainless steel alloy, steel alloy, carbon steel, die steel, spring steel, etc.

Surface treatment: blackening, polishing, anodizing, chrome plating, zinc plating, nickel plating, coloring

Customize products according to customers' specific requirements

Frequently Asked Questions:

Q1: How soon can I get the samples?

3-5 days, 10-15 days for bulk orders.

Q2: How to control product quality?

First full-size inspection - Batch production - Inspection process (3-hour sampling)- random inspection of 100% shipment. We have a professional QC team to control quality during mass production and check complete goods before shipment.

Q3: What information is required for a quotation?

Please provide product drawings in PDF format, preferably DWG or STEP.

End: Merchants who need customized products can send drawings to szbergek for quotation

click request quotation

Related Keywords